|

|

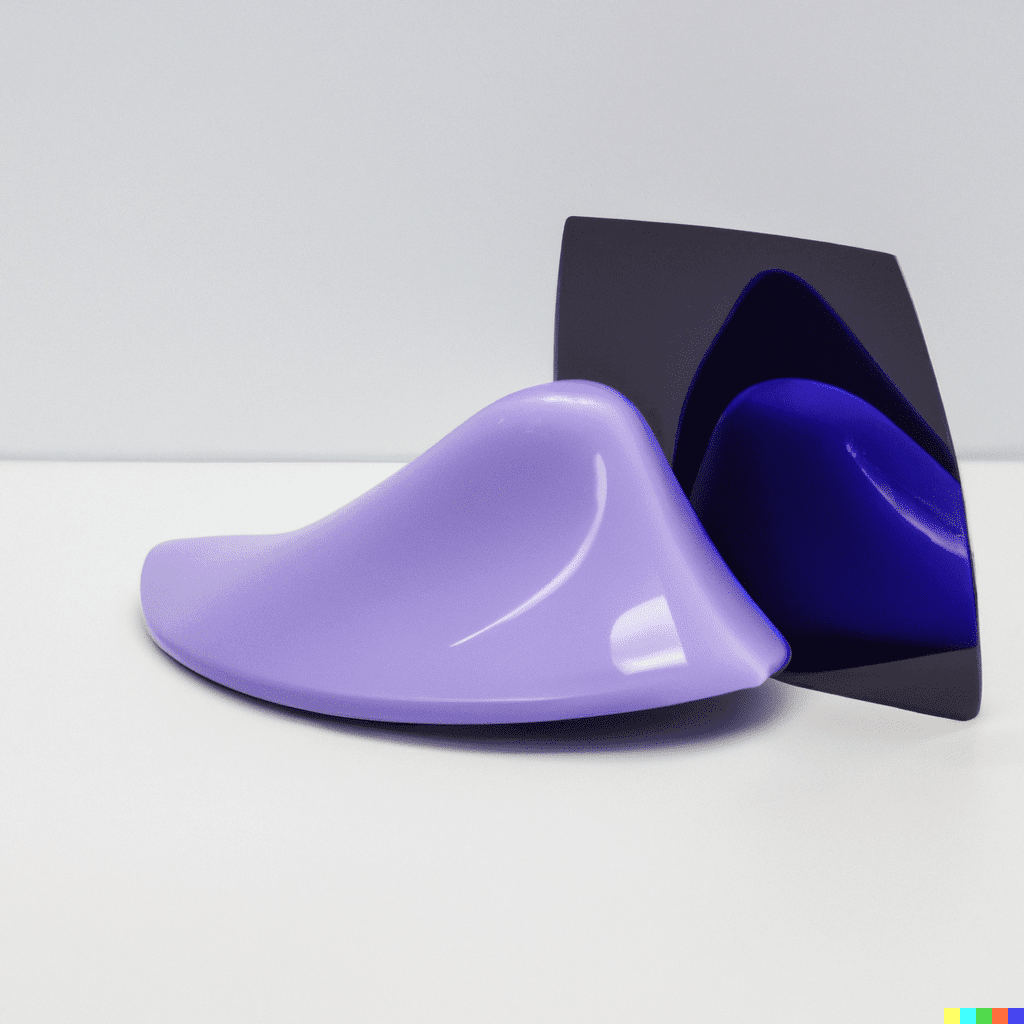

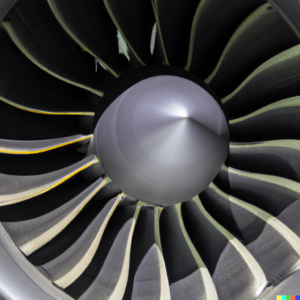

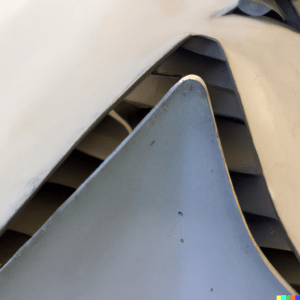

Tensile Strength: 60-70 MPa

Impact Strength: 10-20 kJ/m²

Heat Deflection Temperature: 135-150°C

|

Transparent or translucent

Good dimensional stability

|

Resistant to many chemicals and oils

|

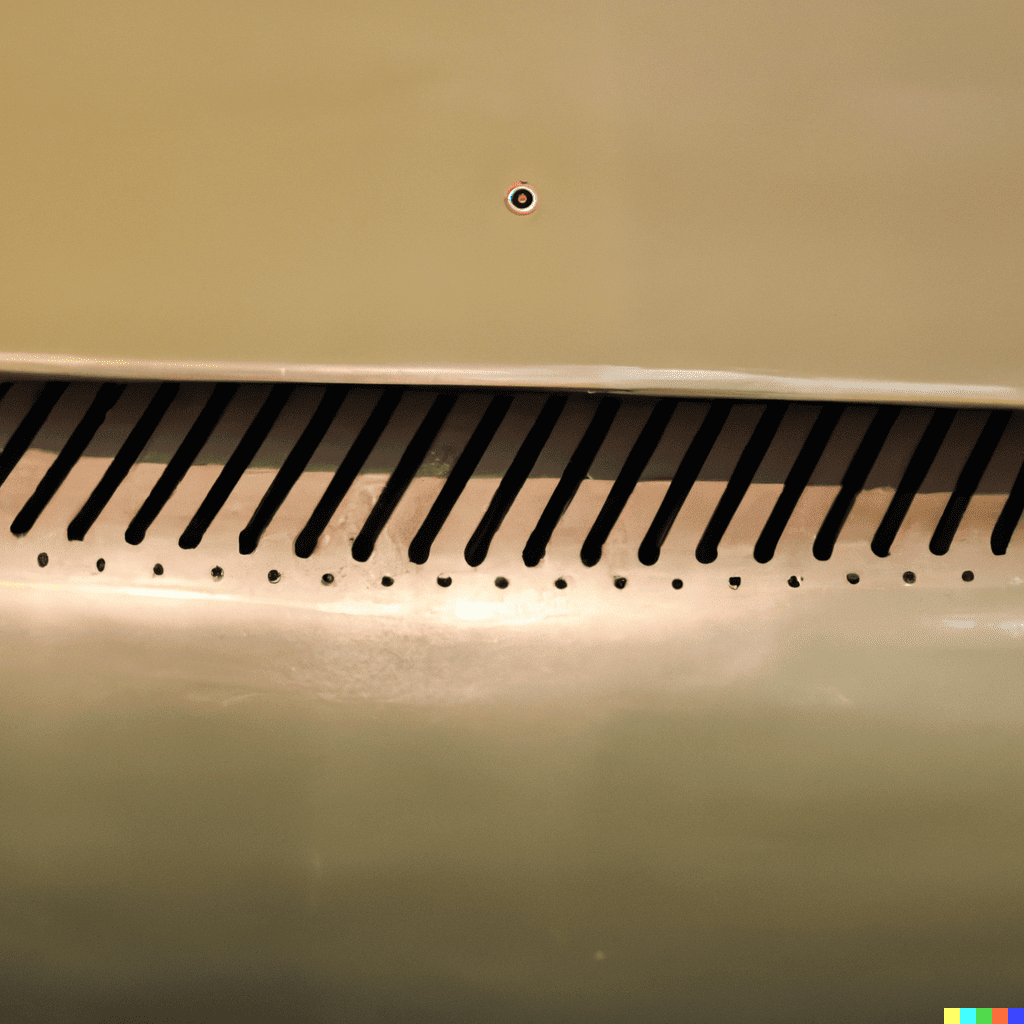

Excellent transparency

High temperature resistance

|

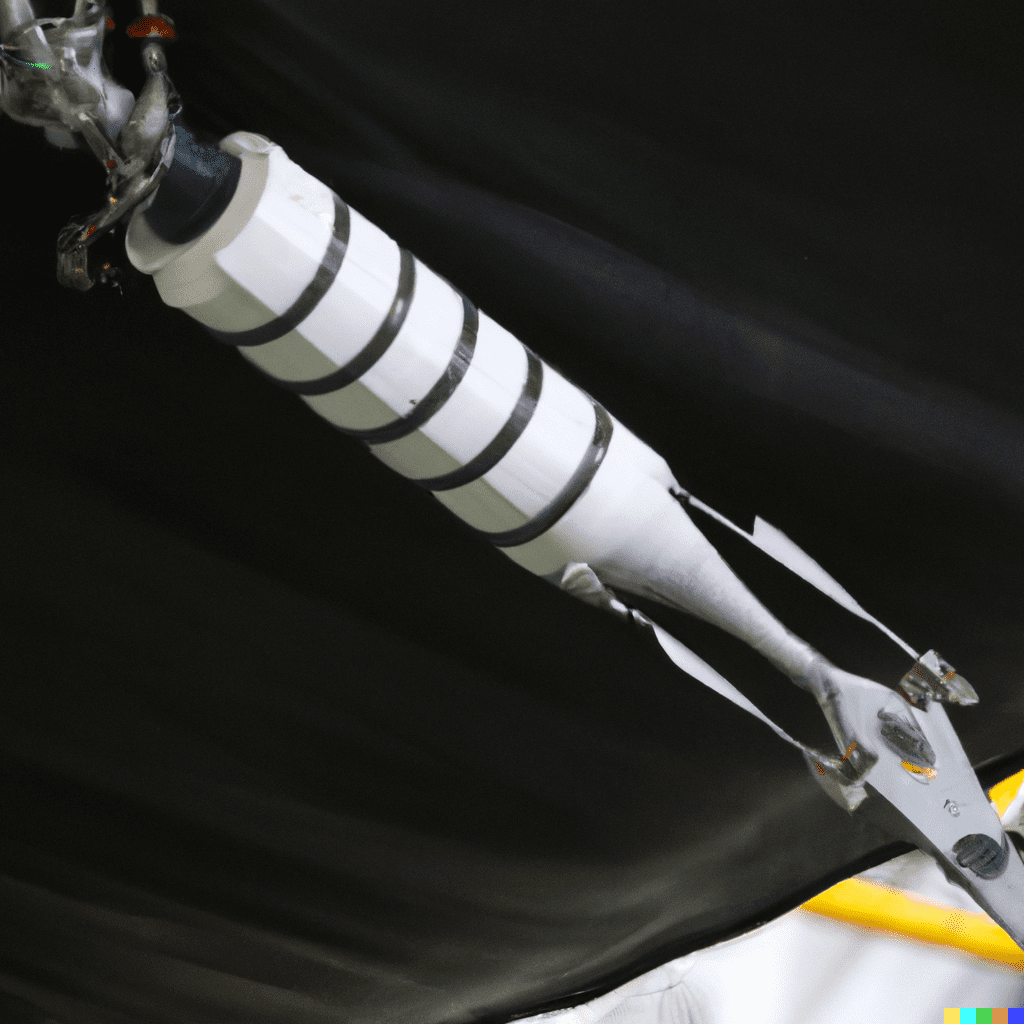

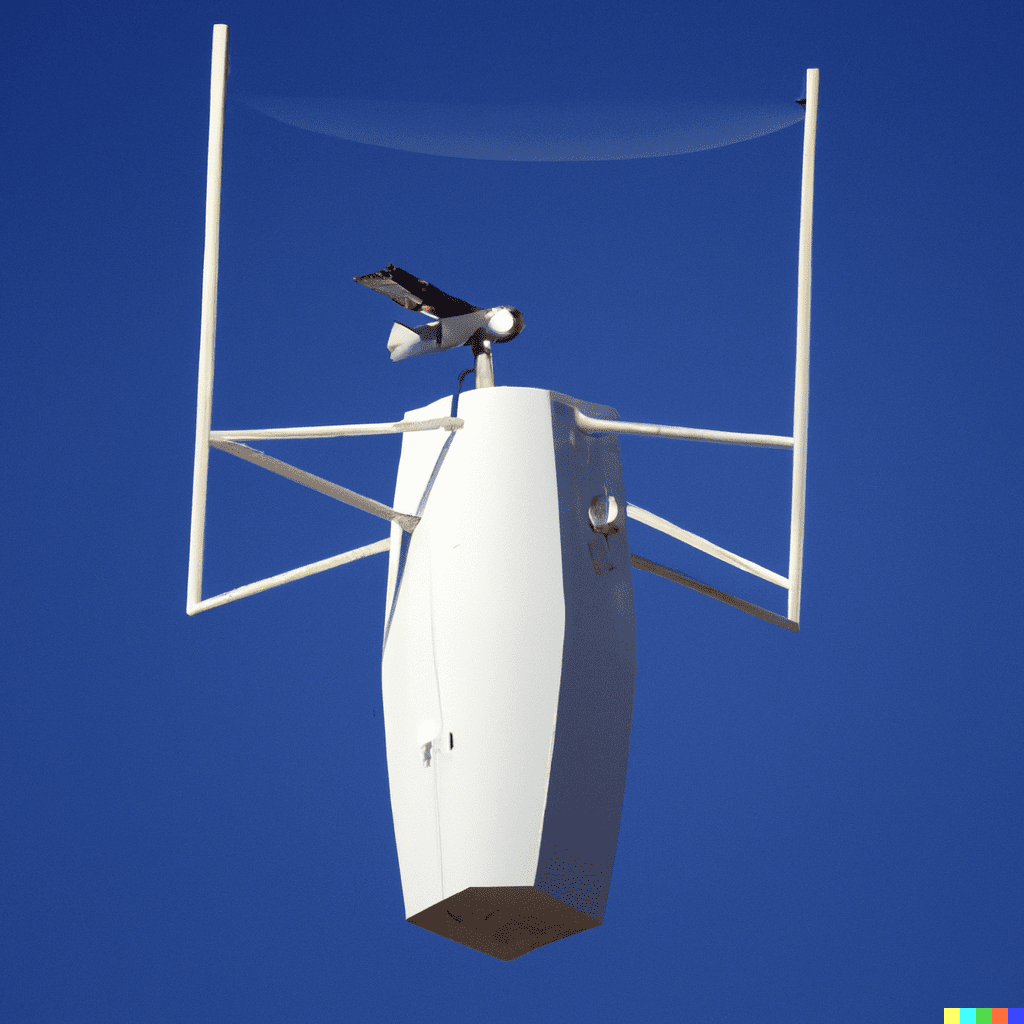

Aerospace and Defense: Transparent canopies, Medical: Medical device components |

|

|

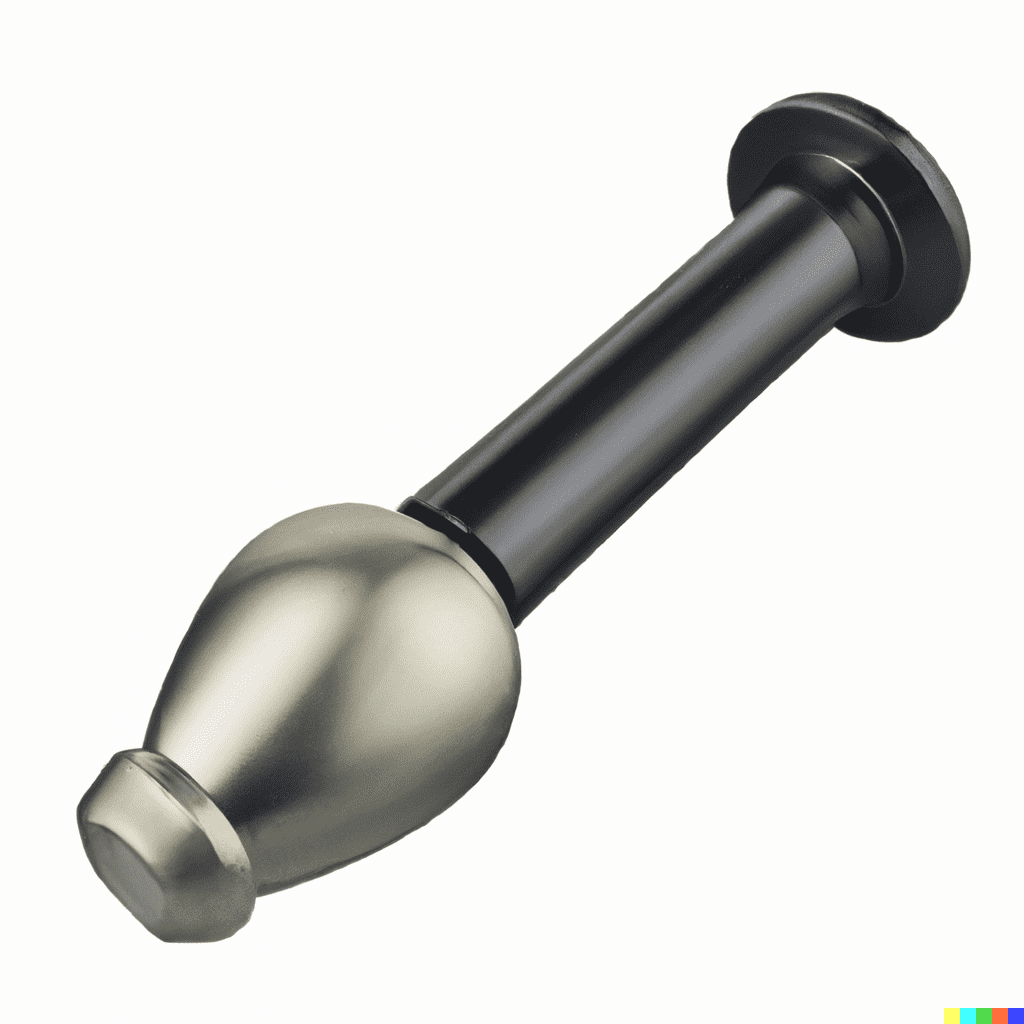

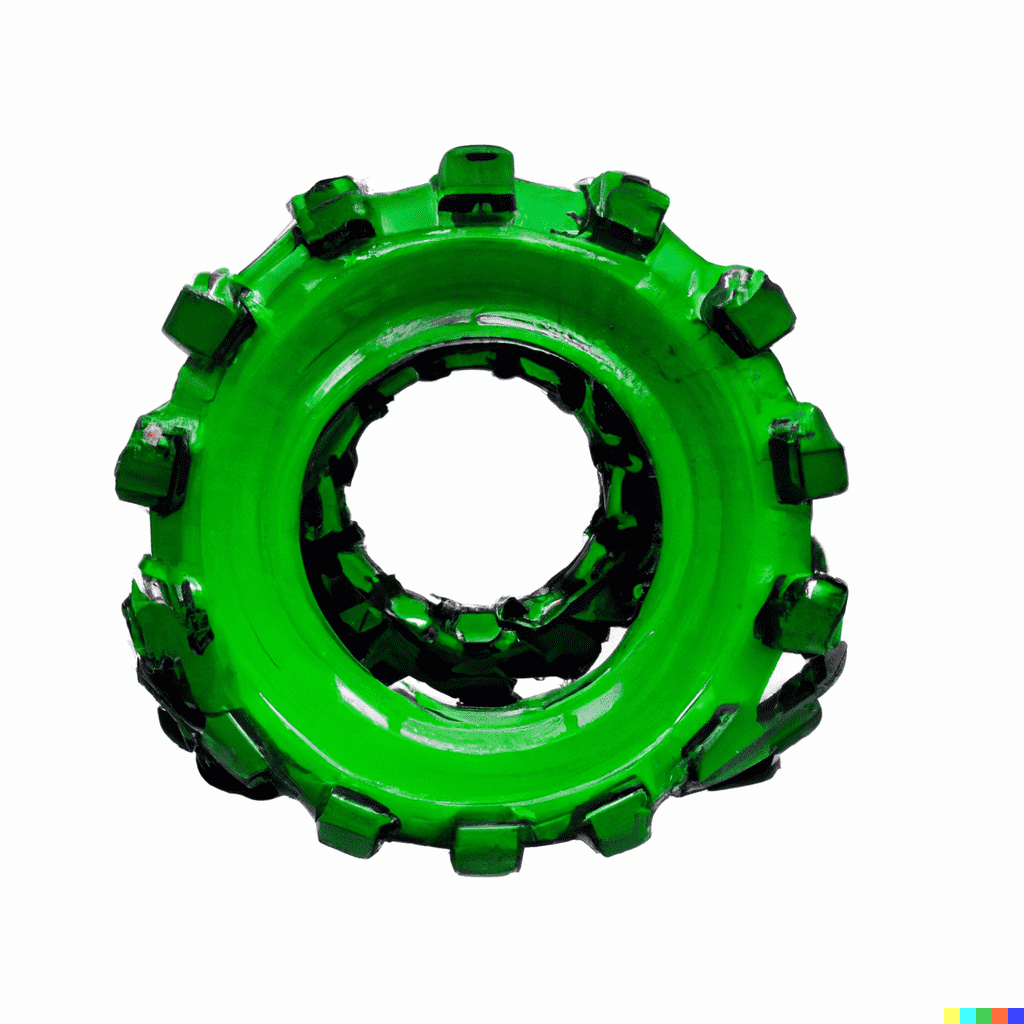

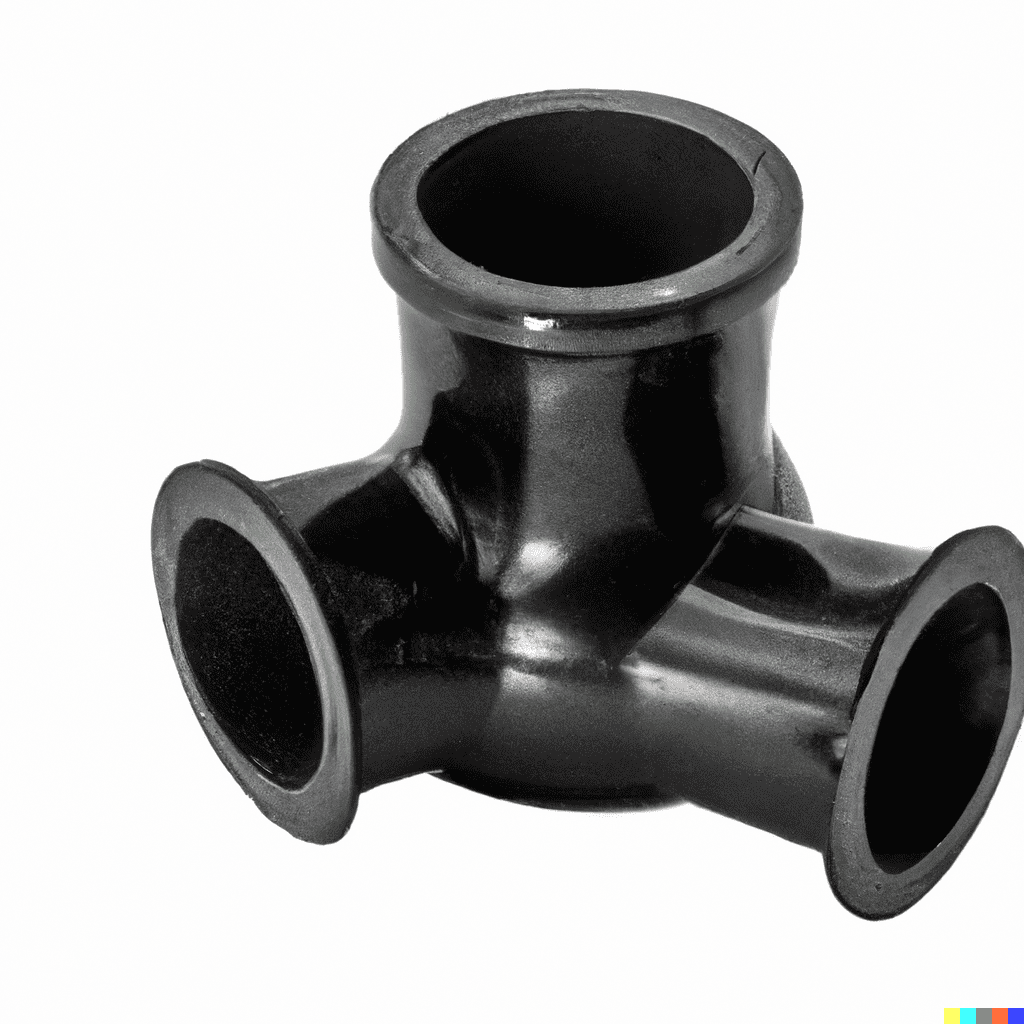

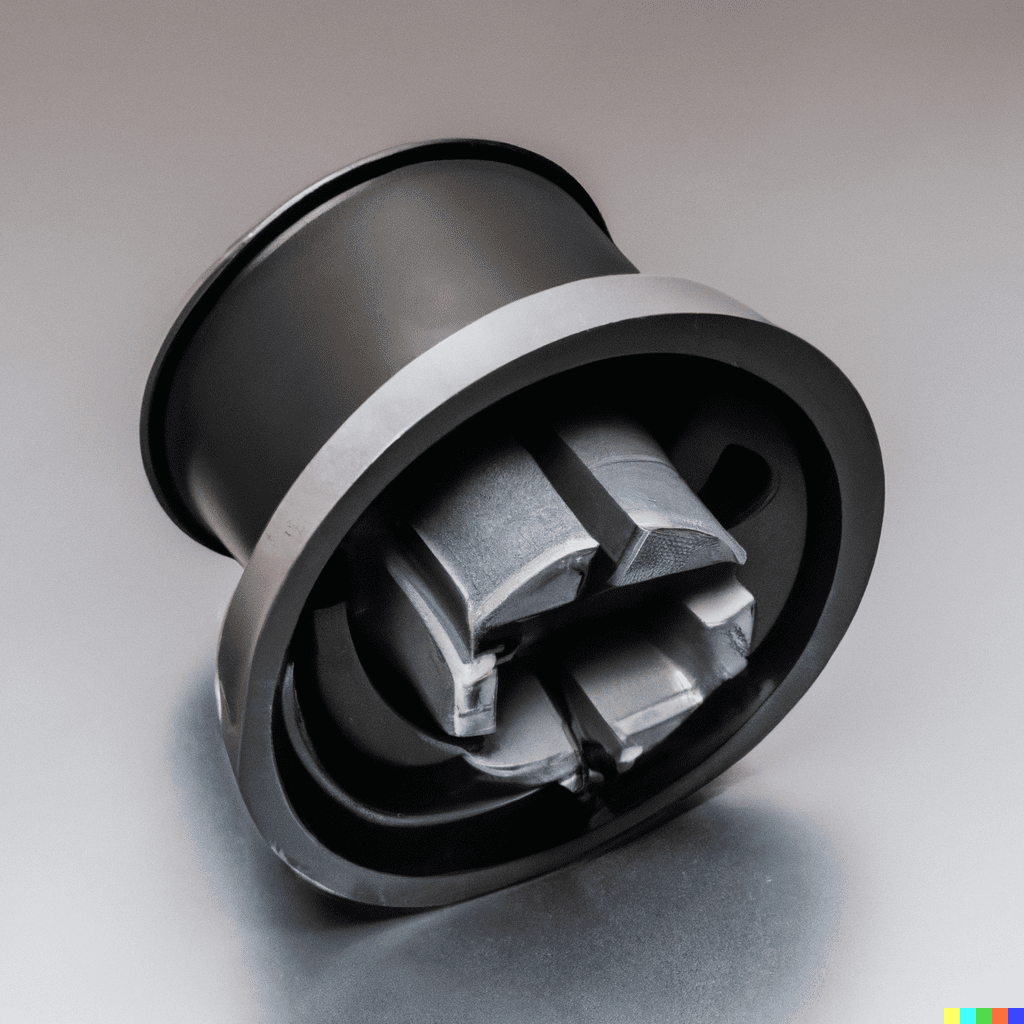

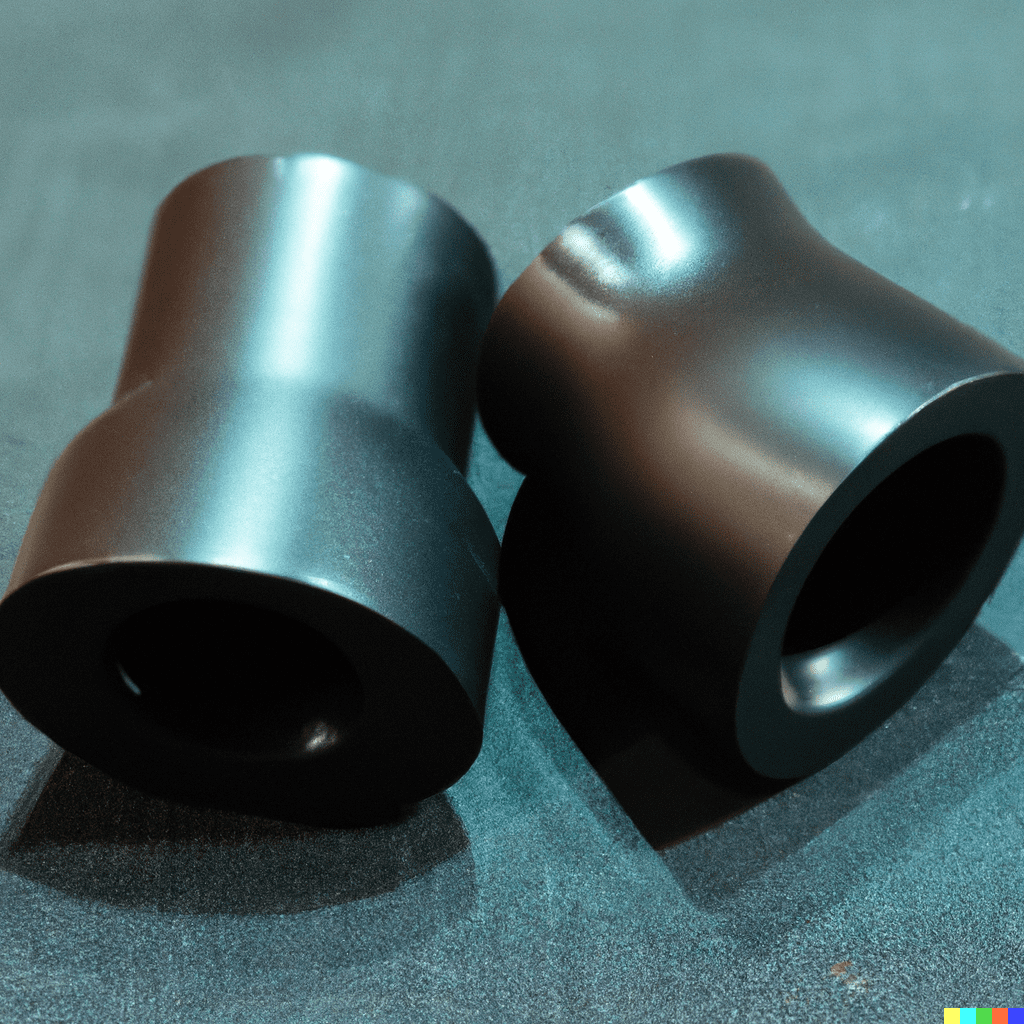

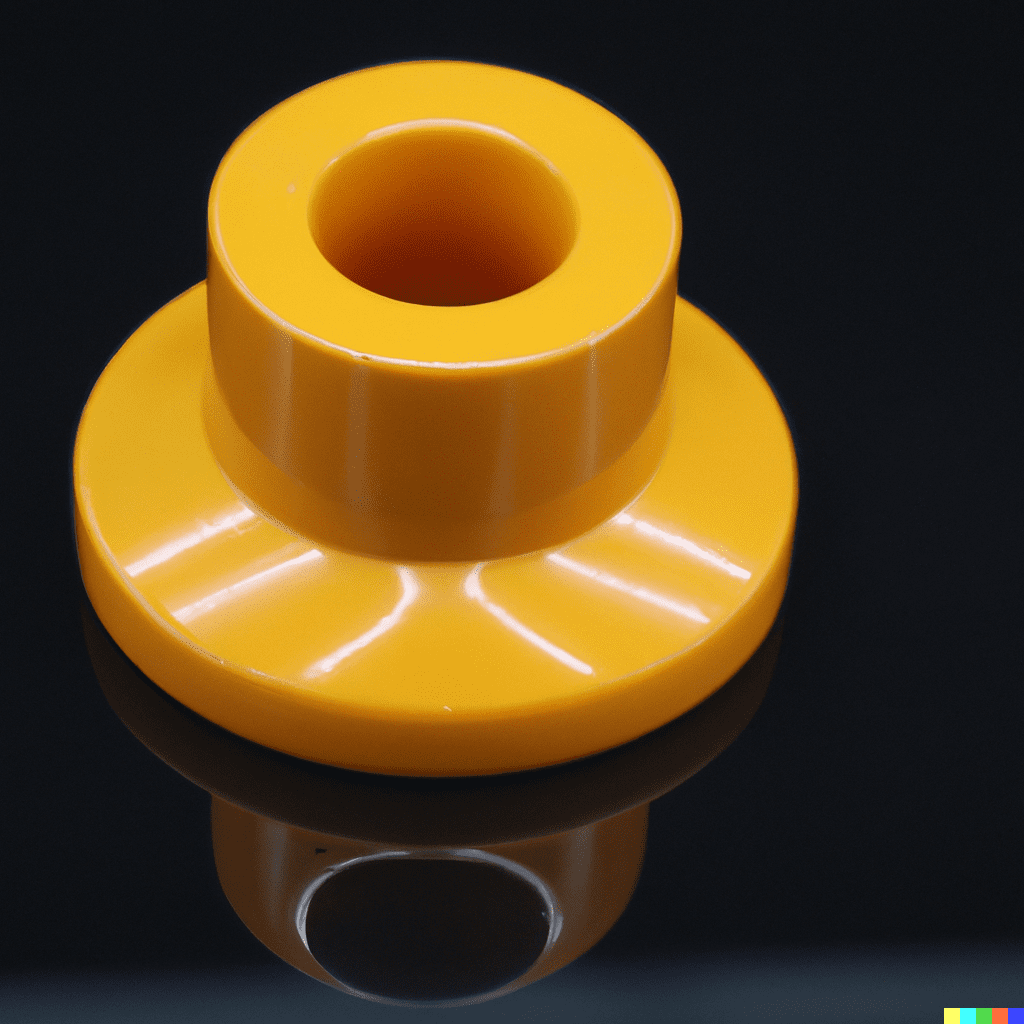

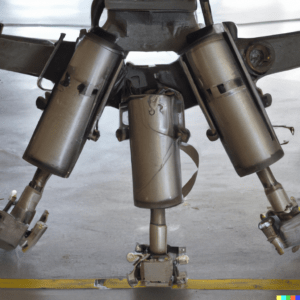

Tensile Strength: 40-60 MPa

Impact Strength: 5-20 kJ/m²

Heat Deflection Temperature: 100-120°C

|

Various colors available

Good dimensional stability

|

Resistant to many chemicals and oils

|

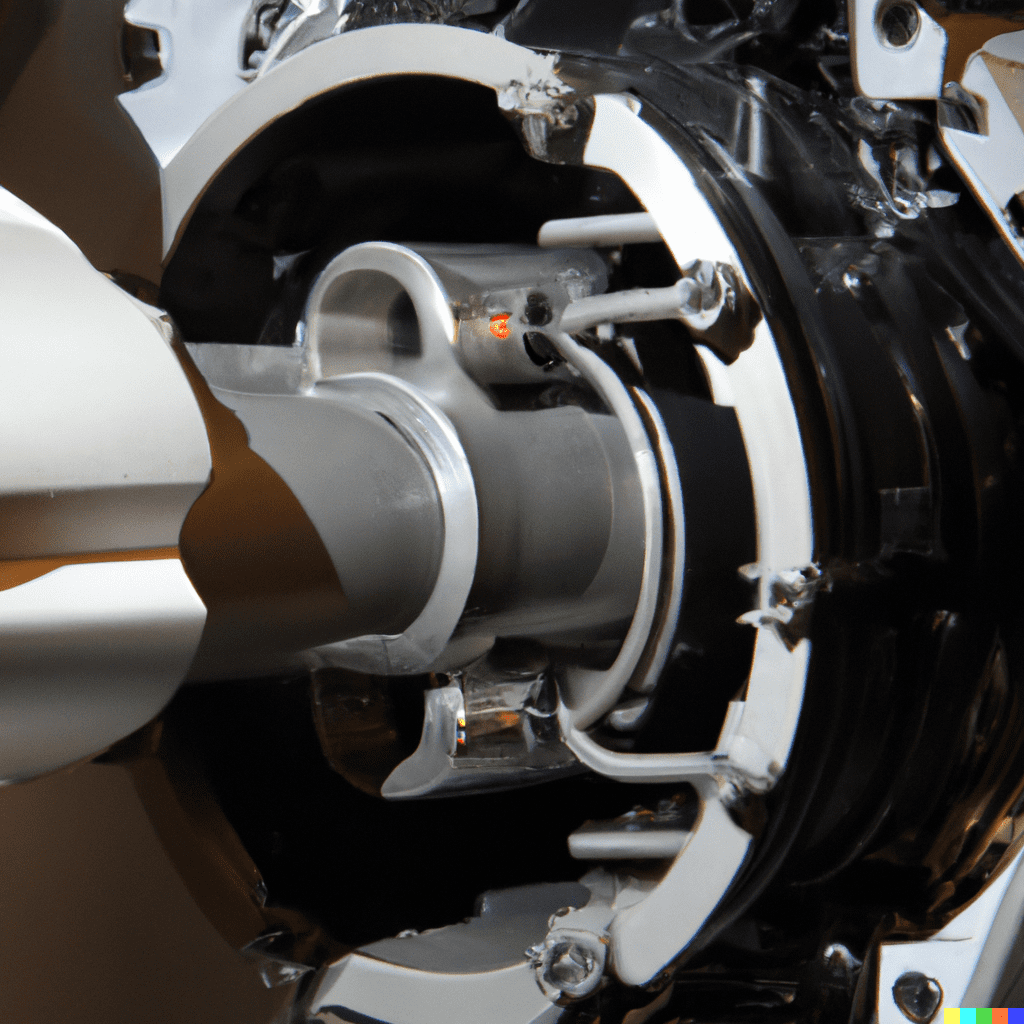

Suitable for high-temperature applications |

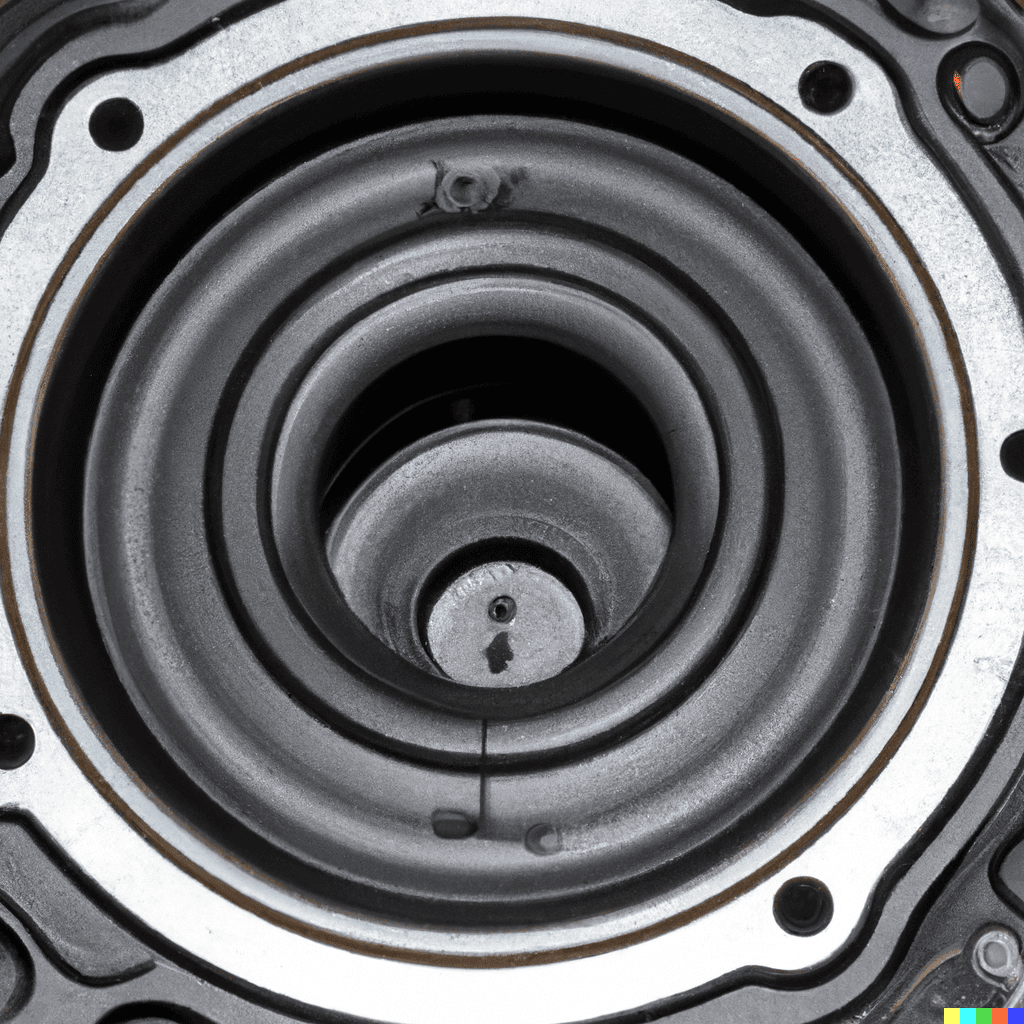

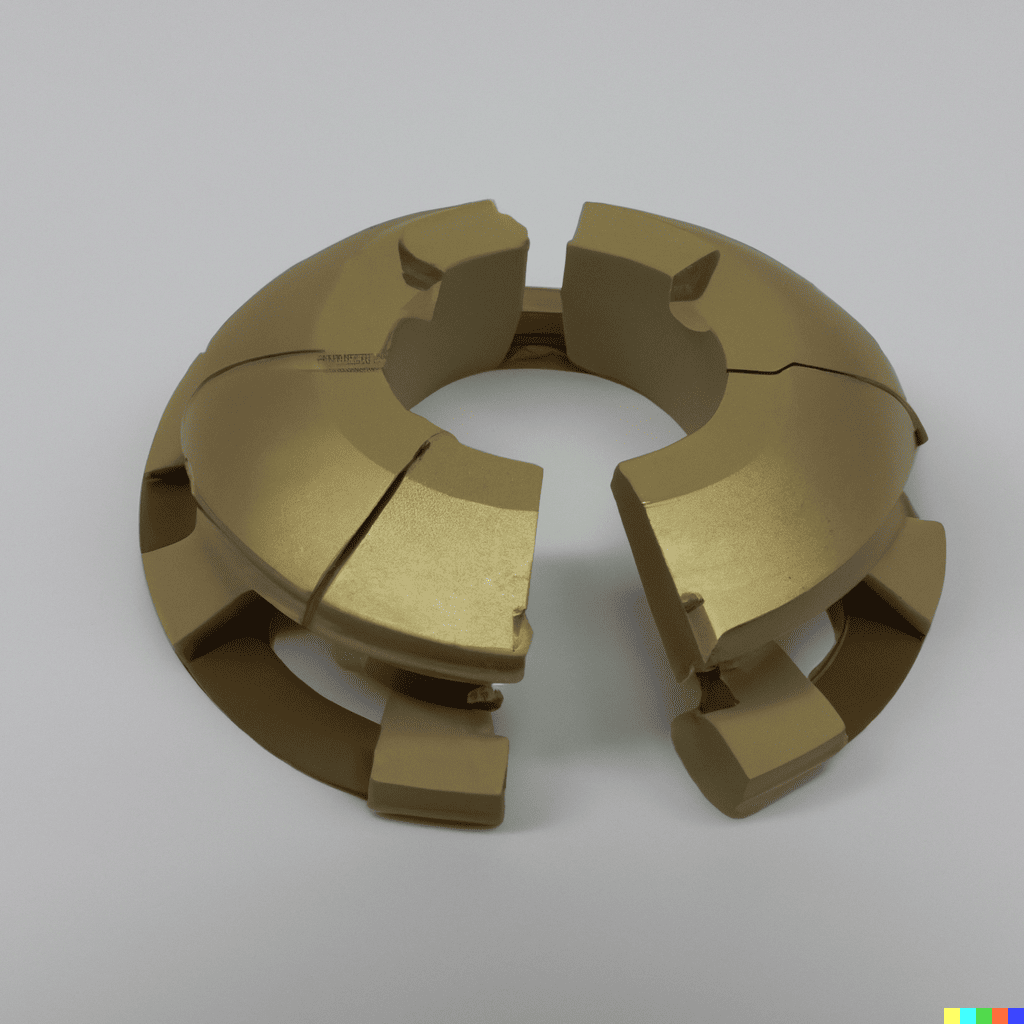

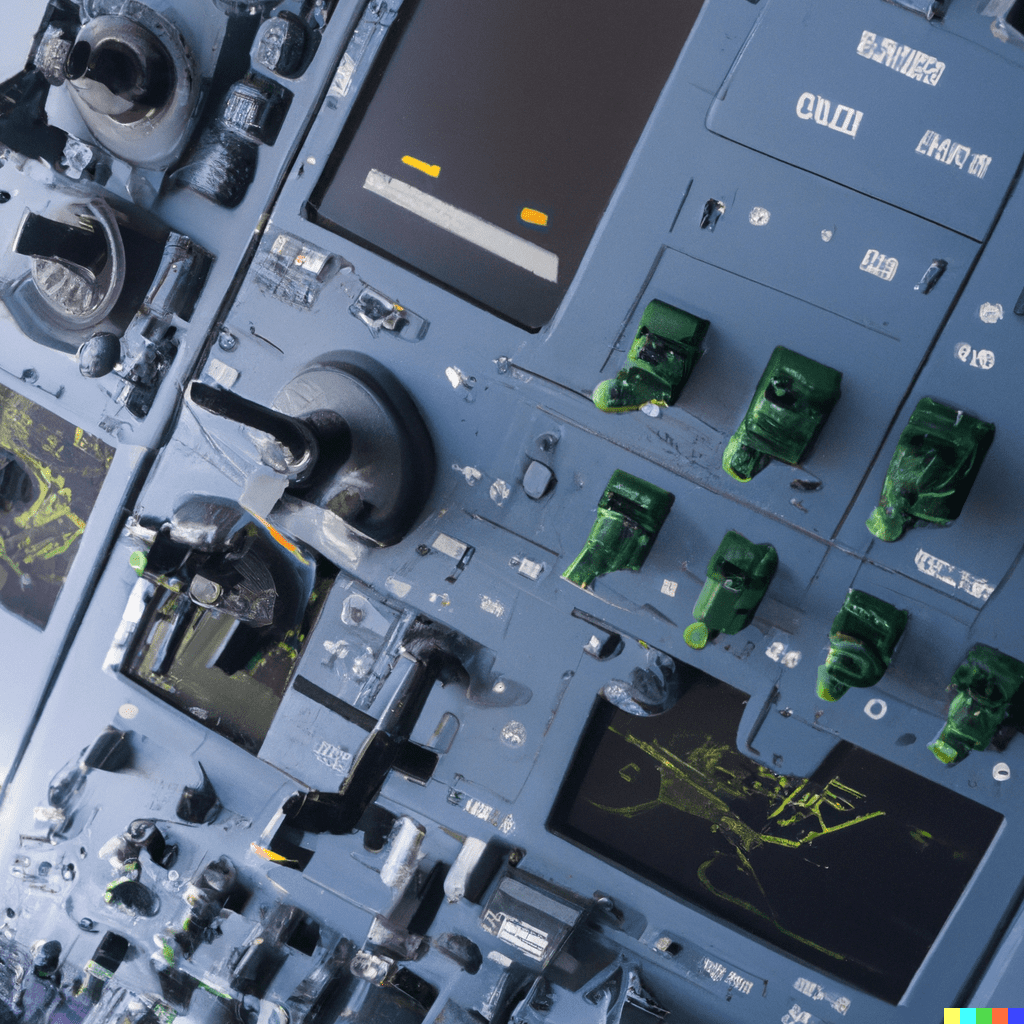

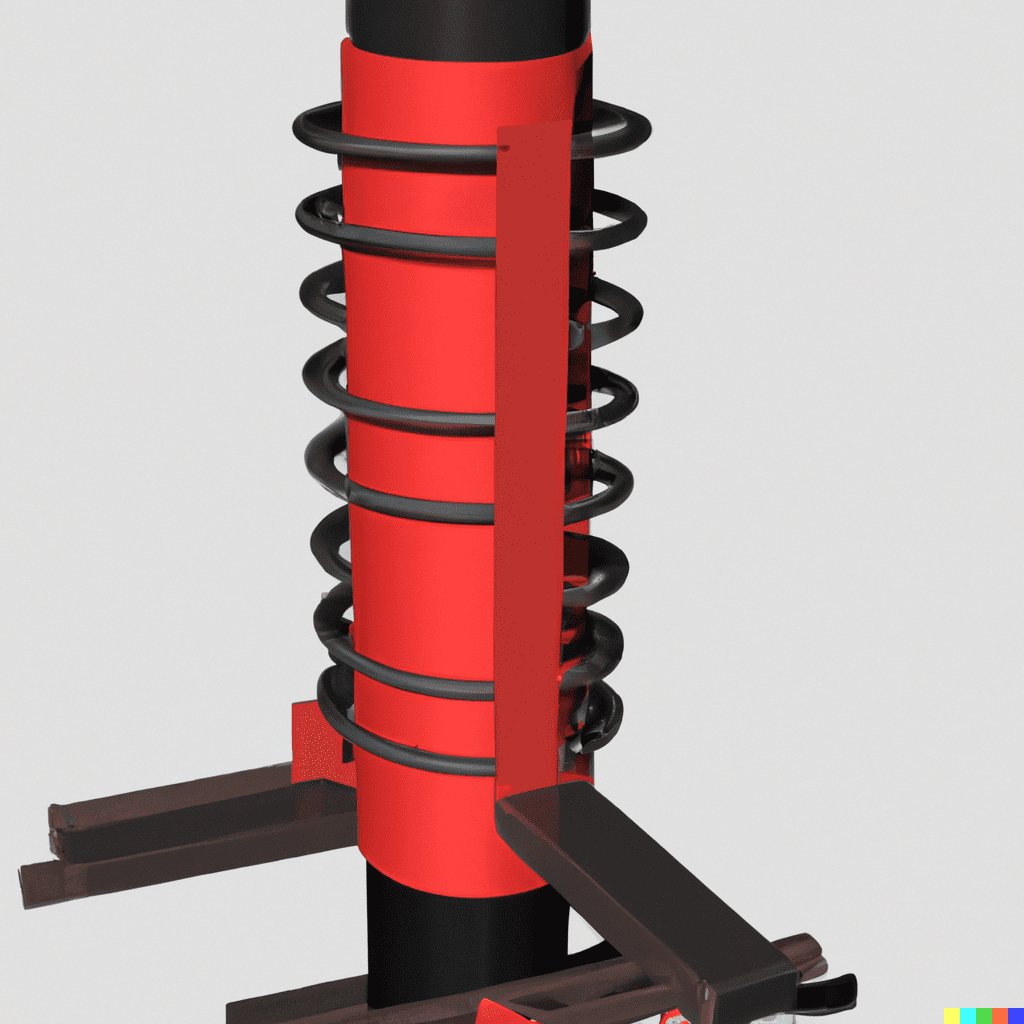

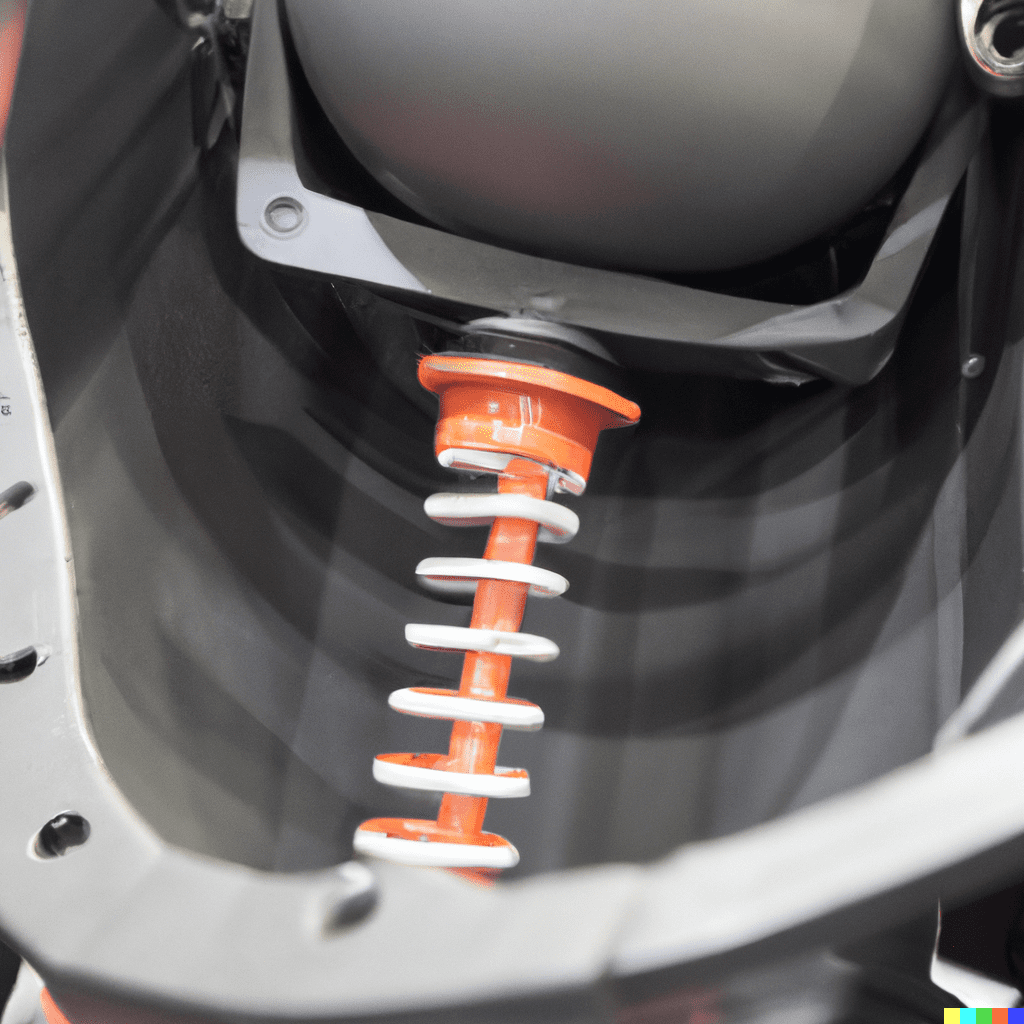

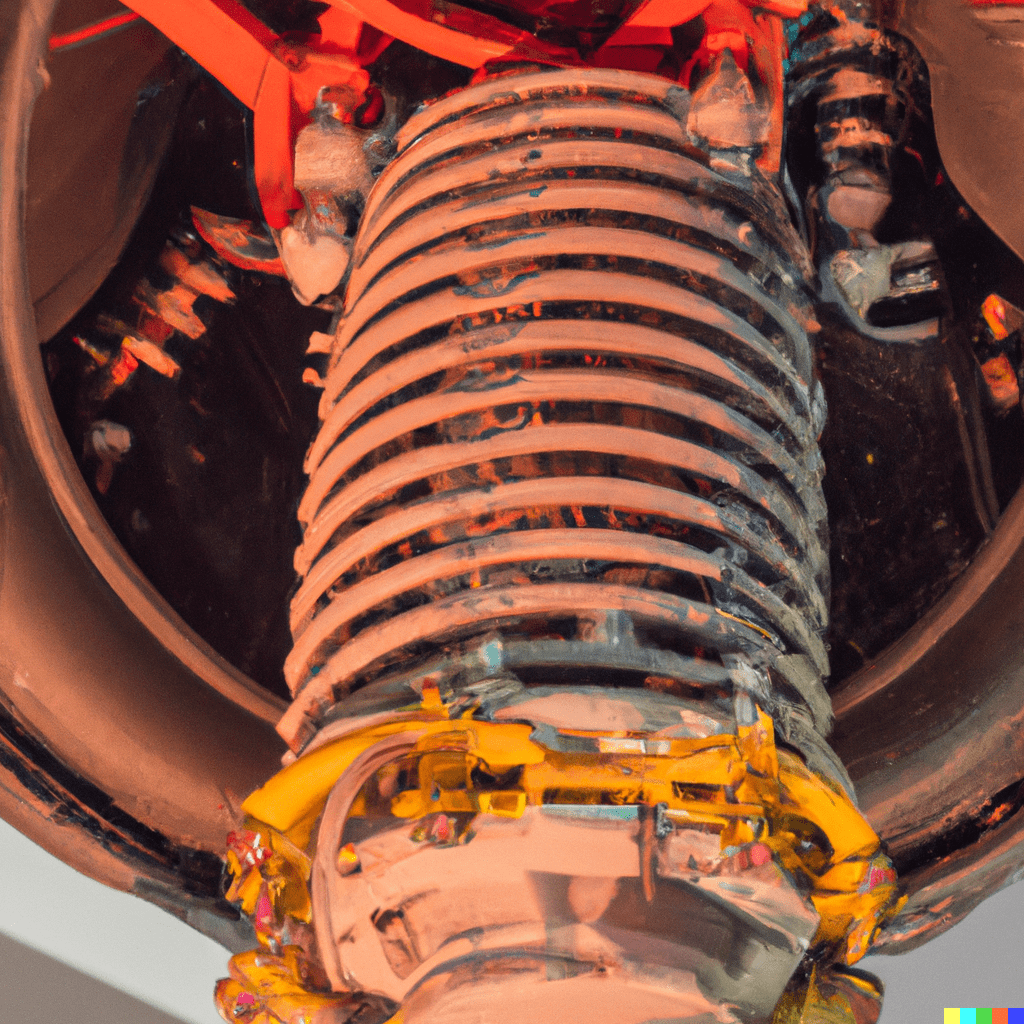

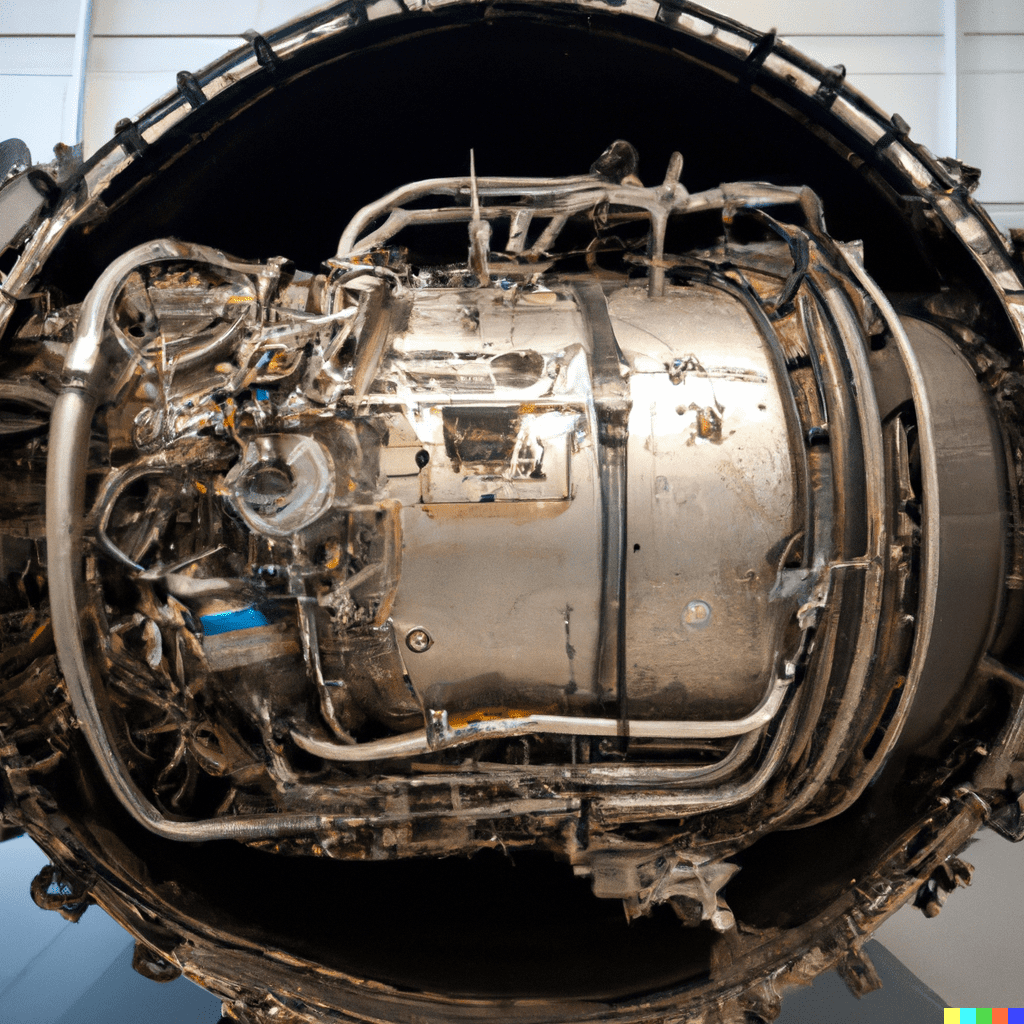

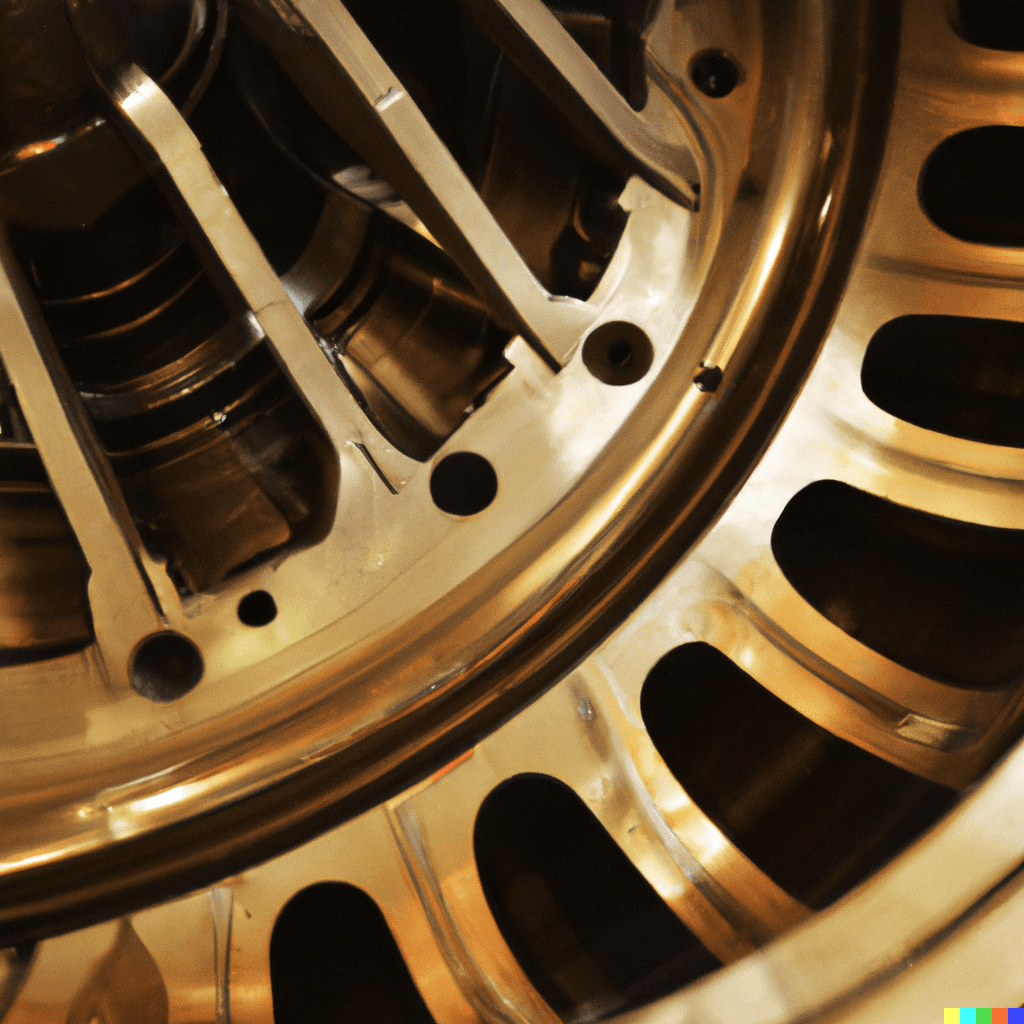

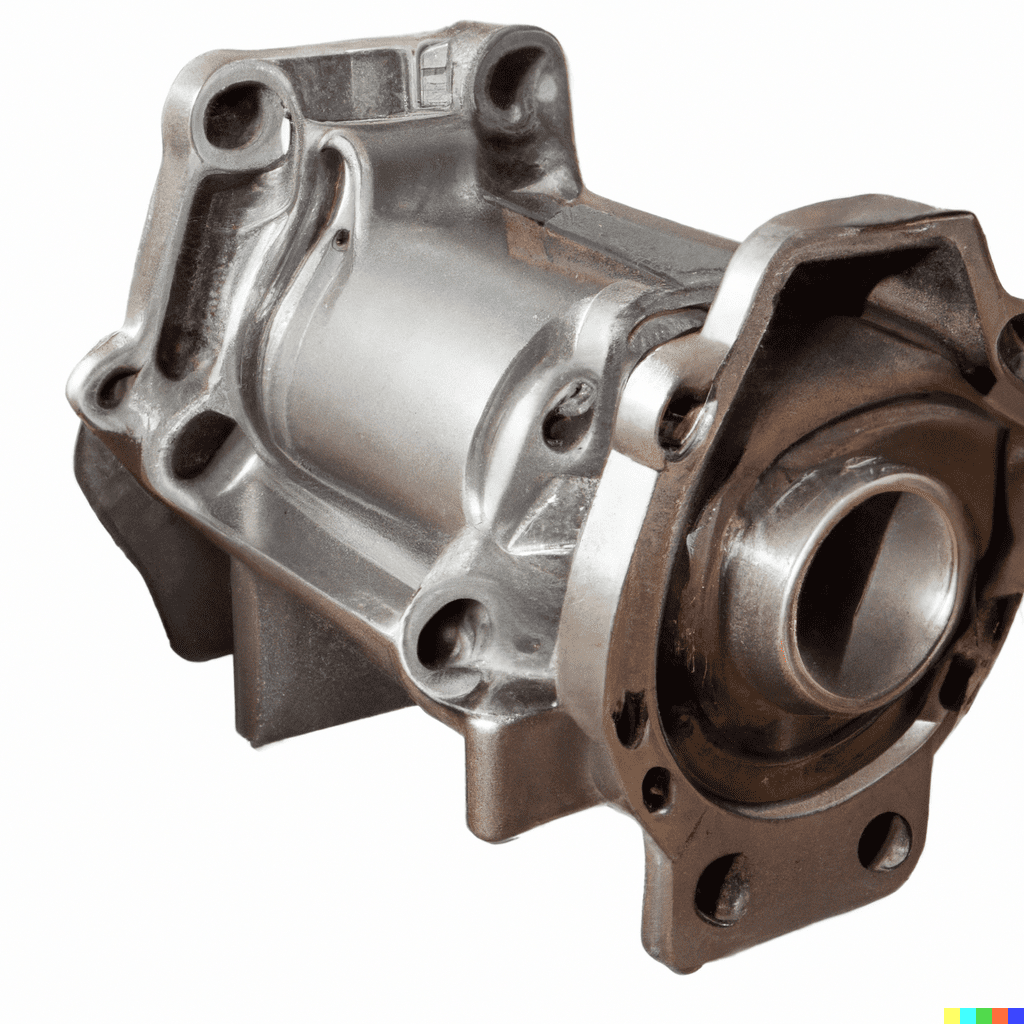

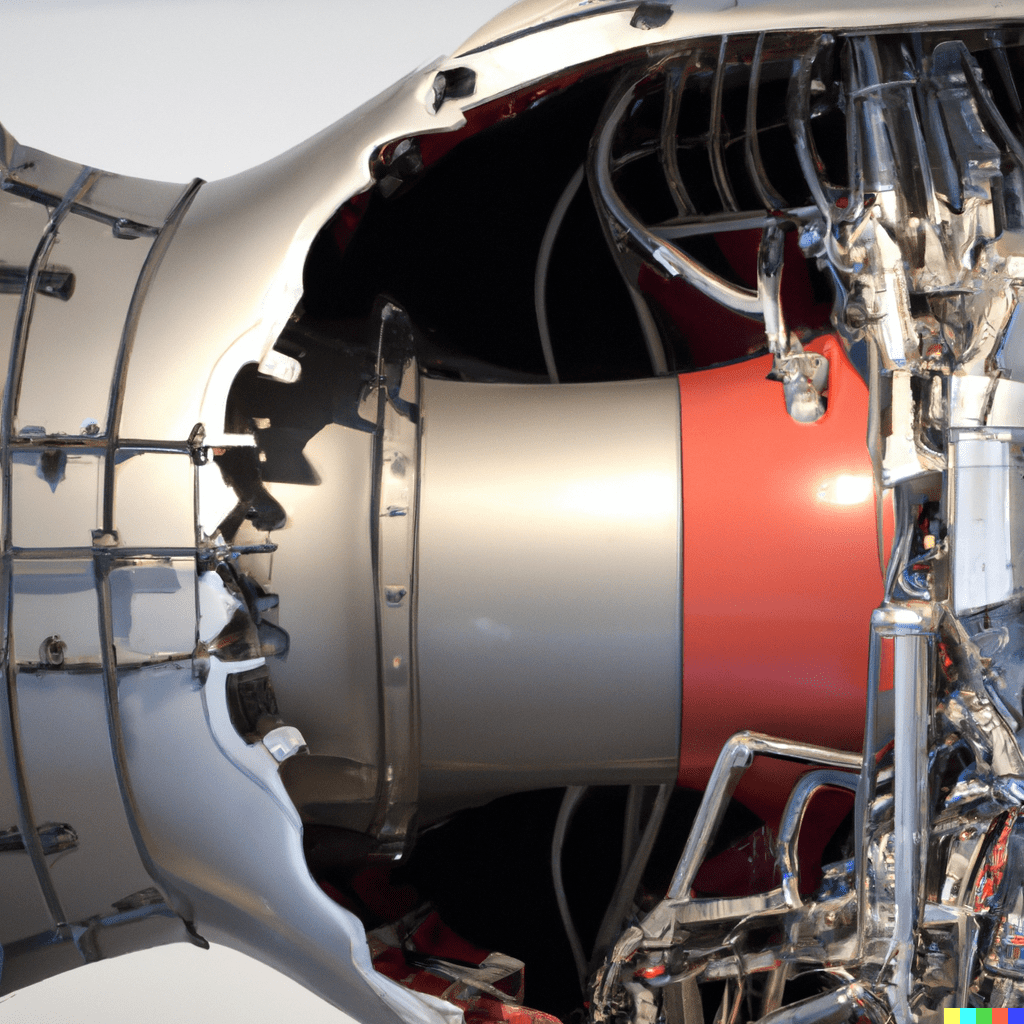

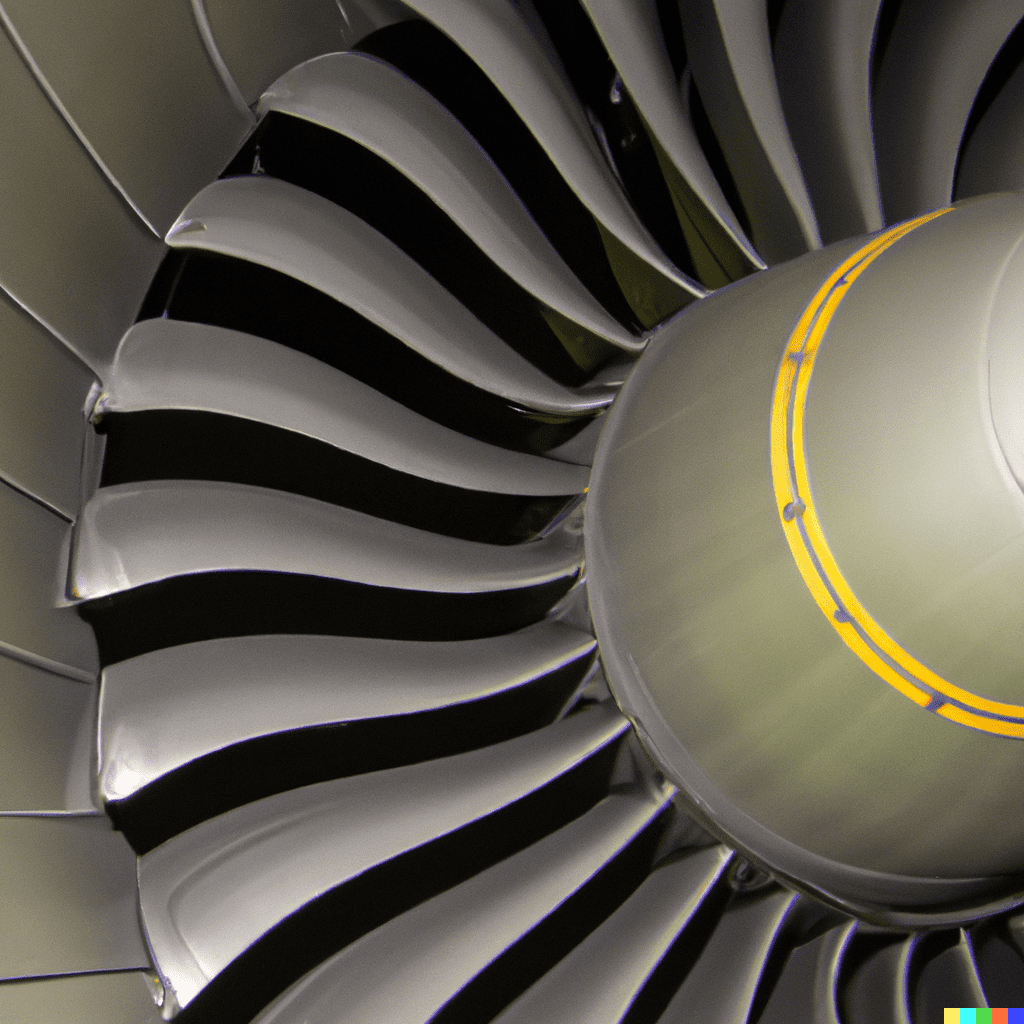

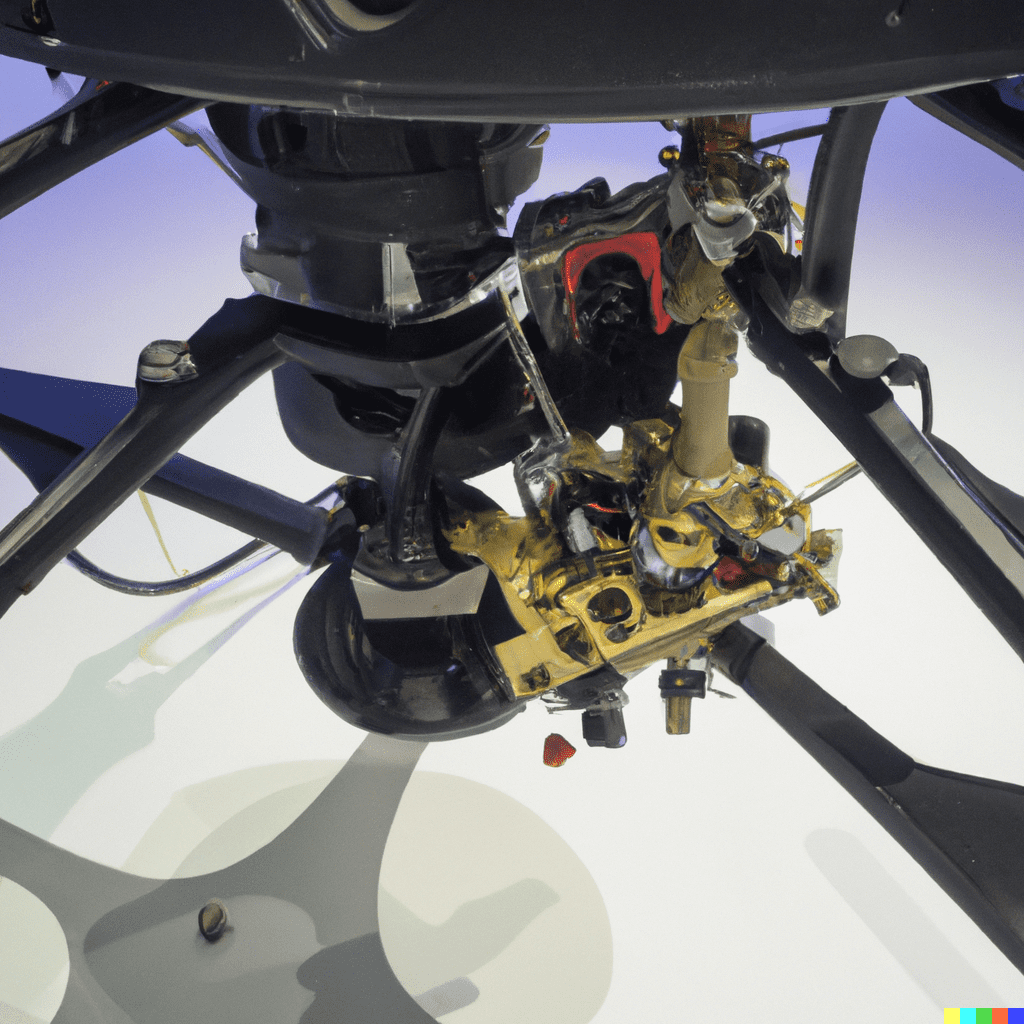

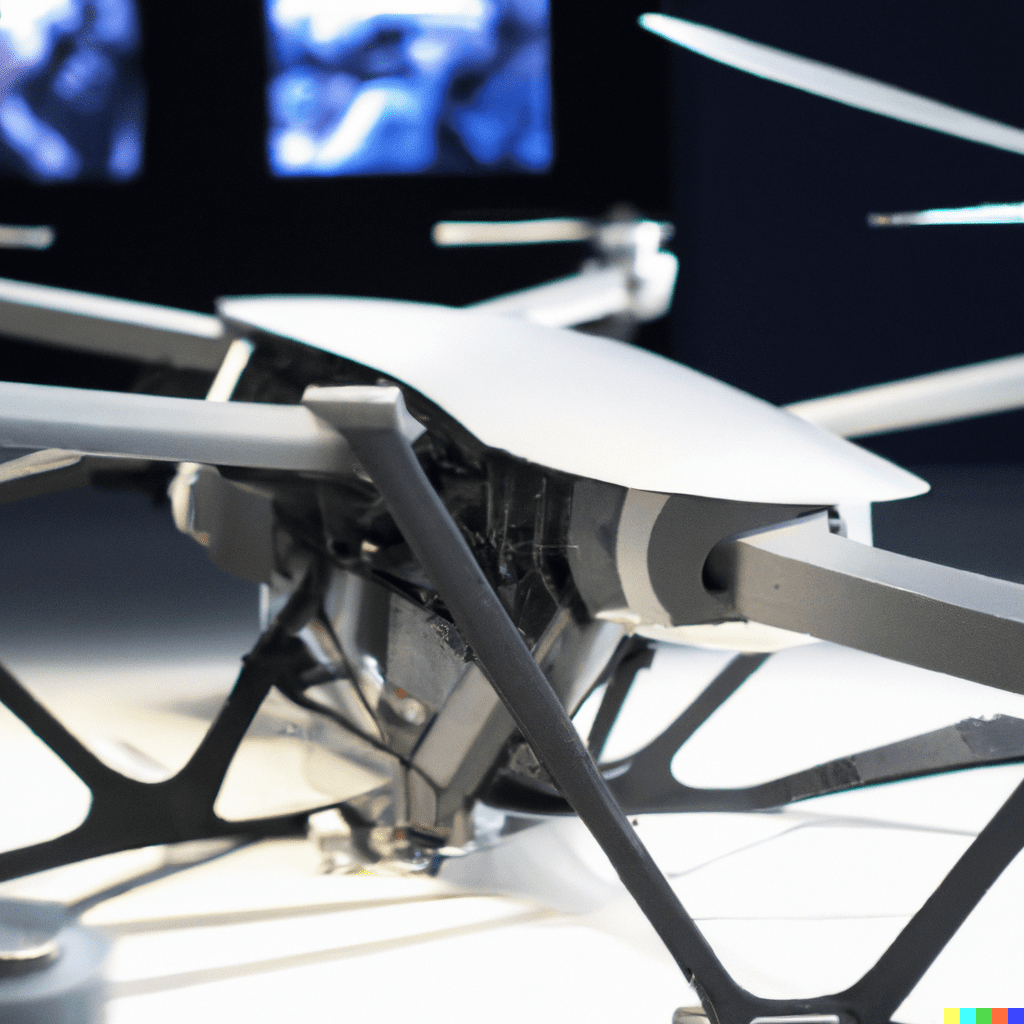

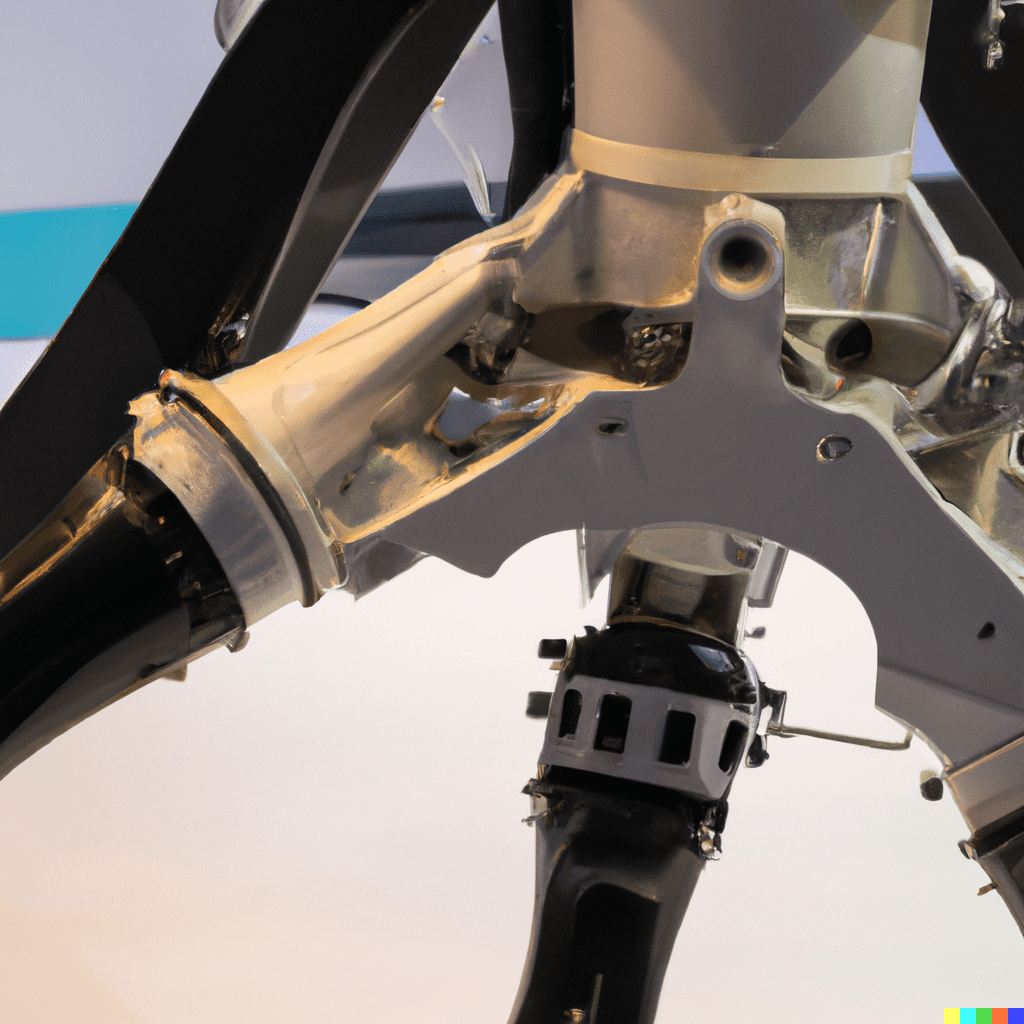

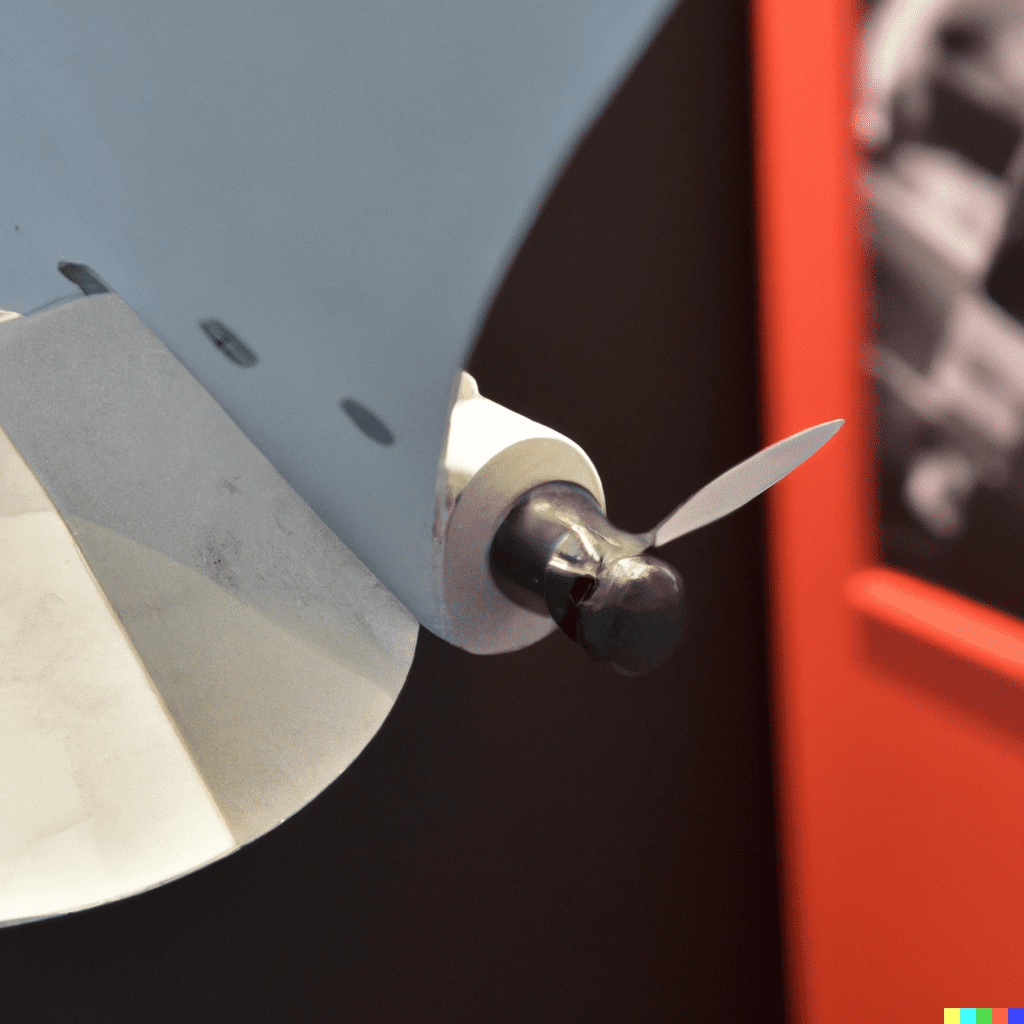

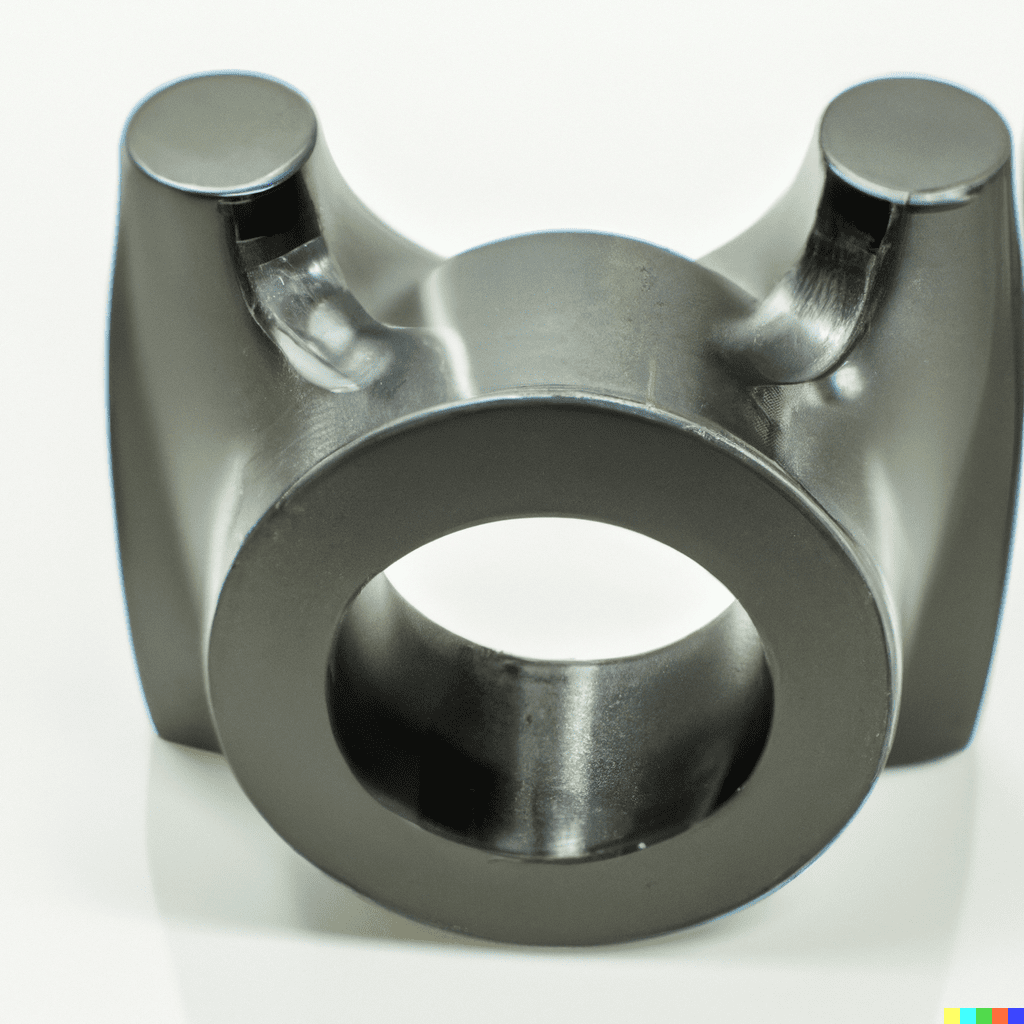

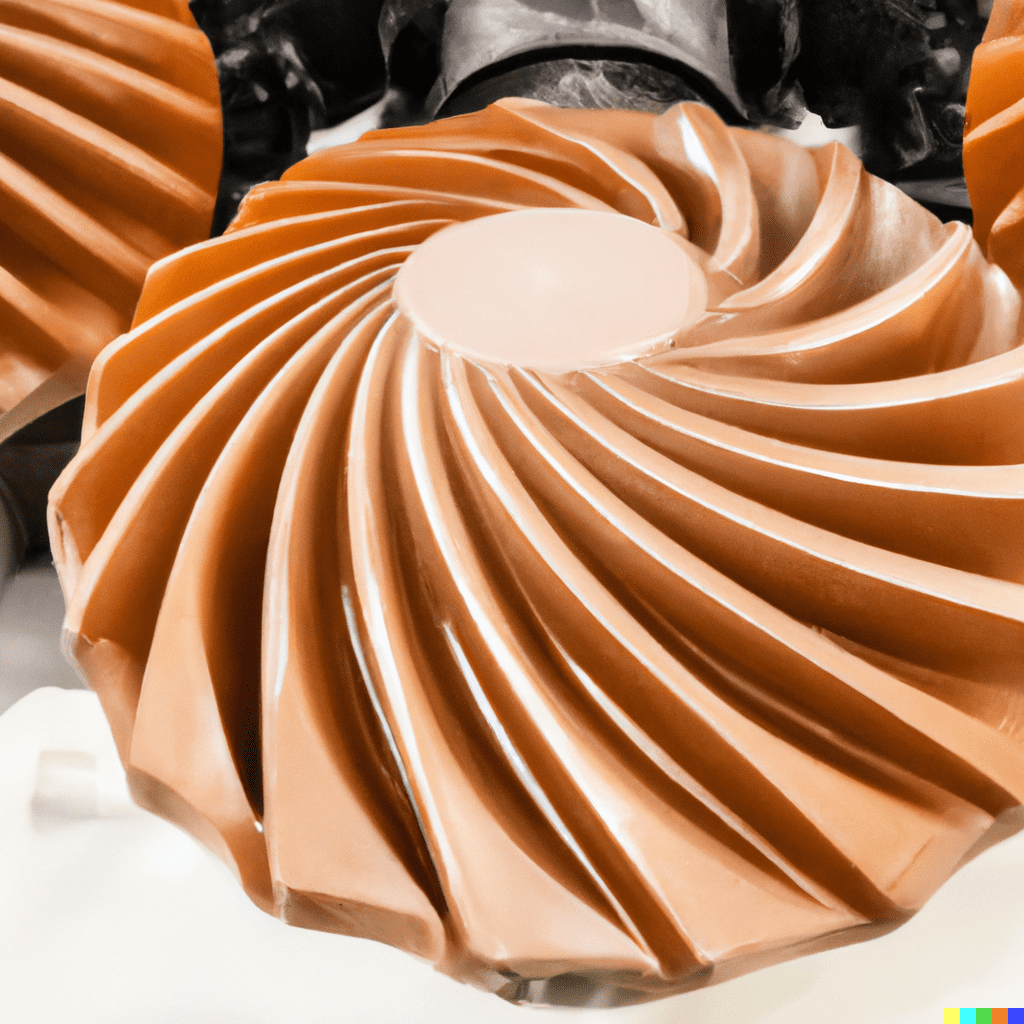

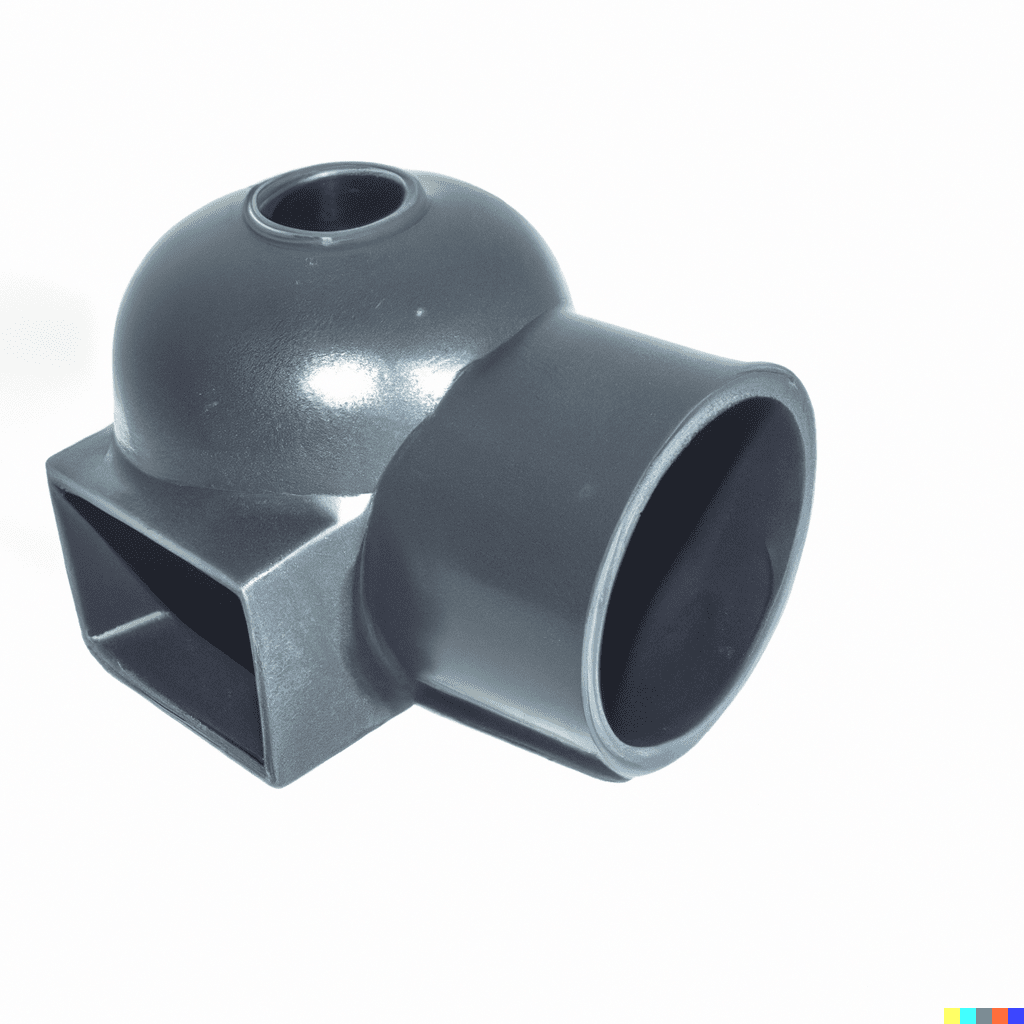

Aerospace and Defense: Engine components, Automotive: Engine components |

|

|

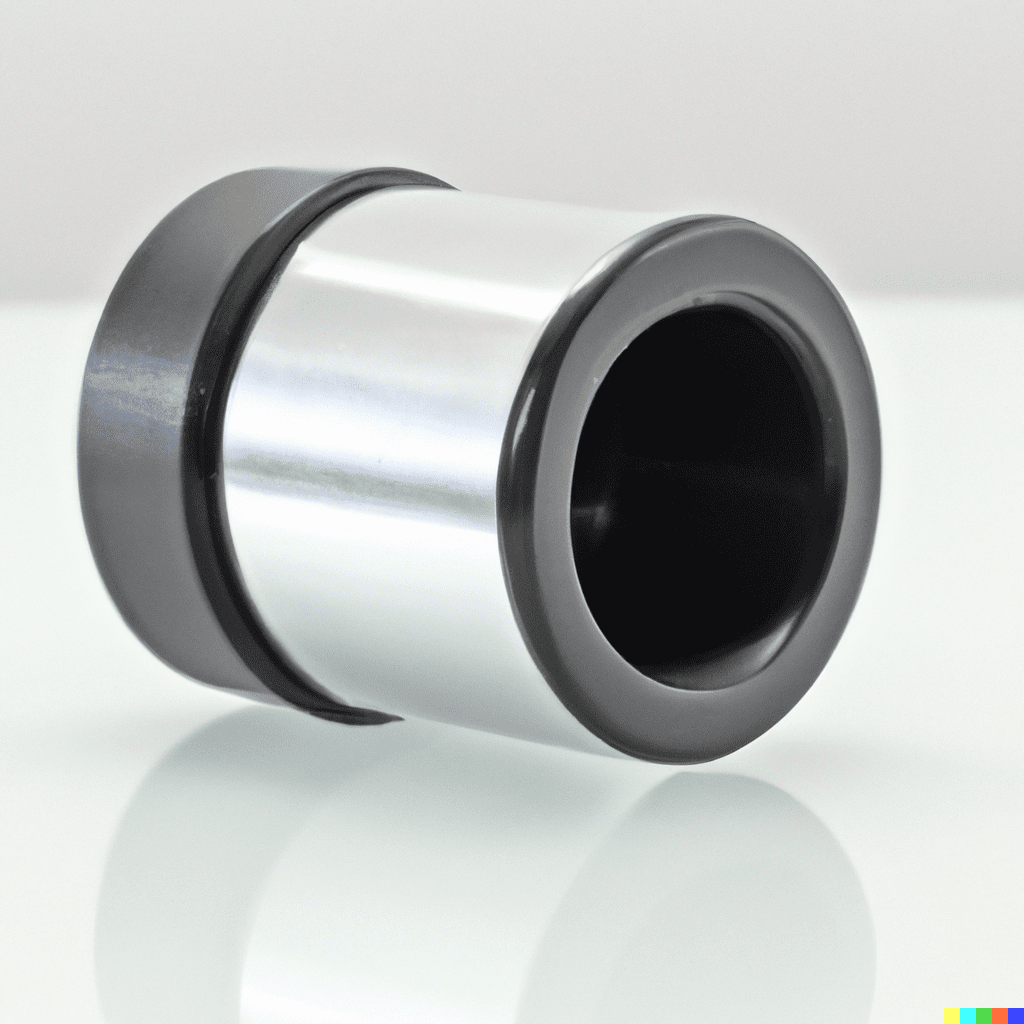

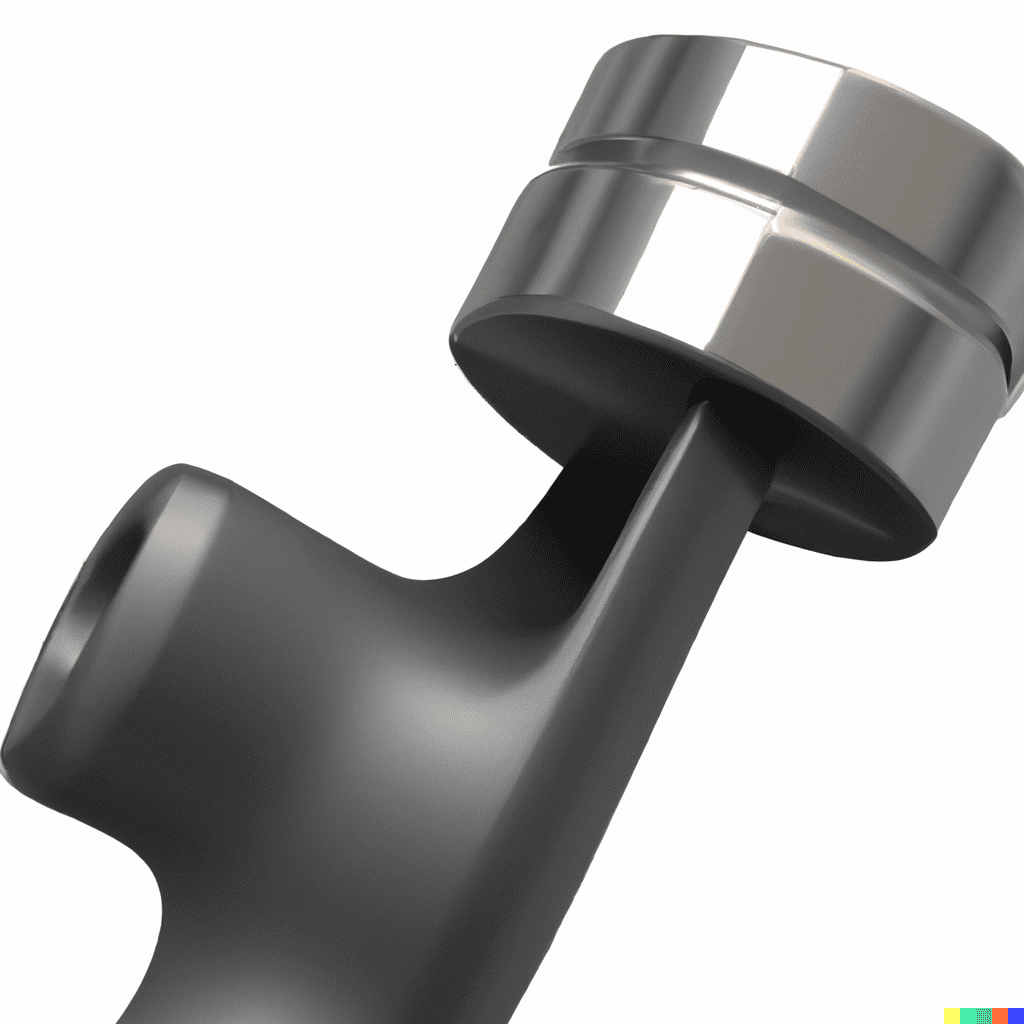

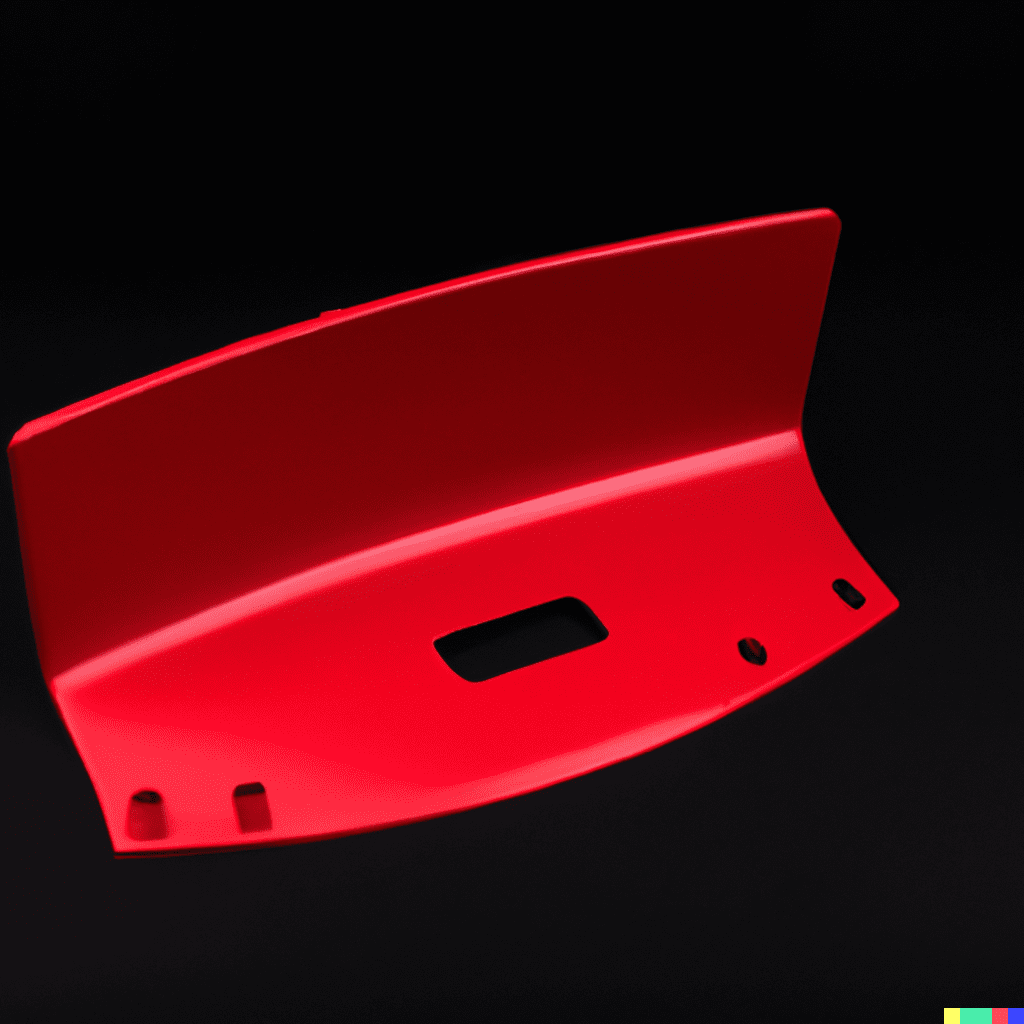

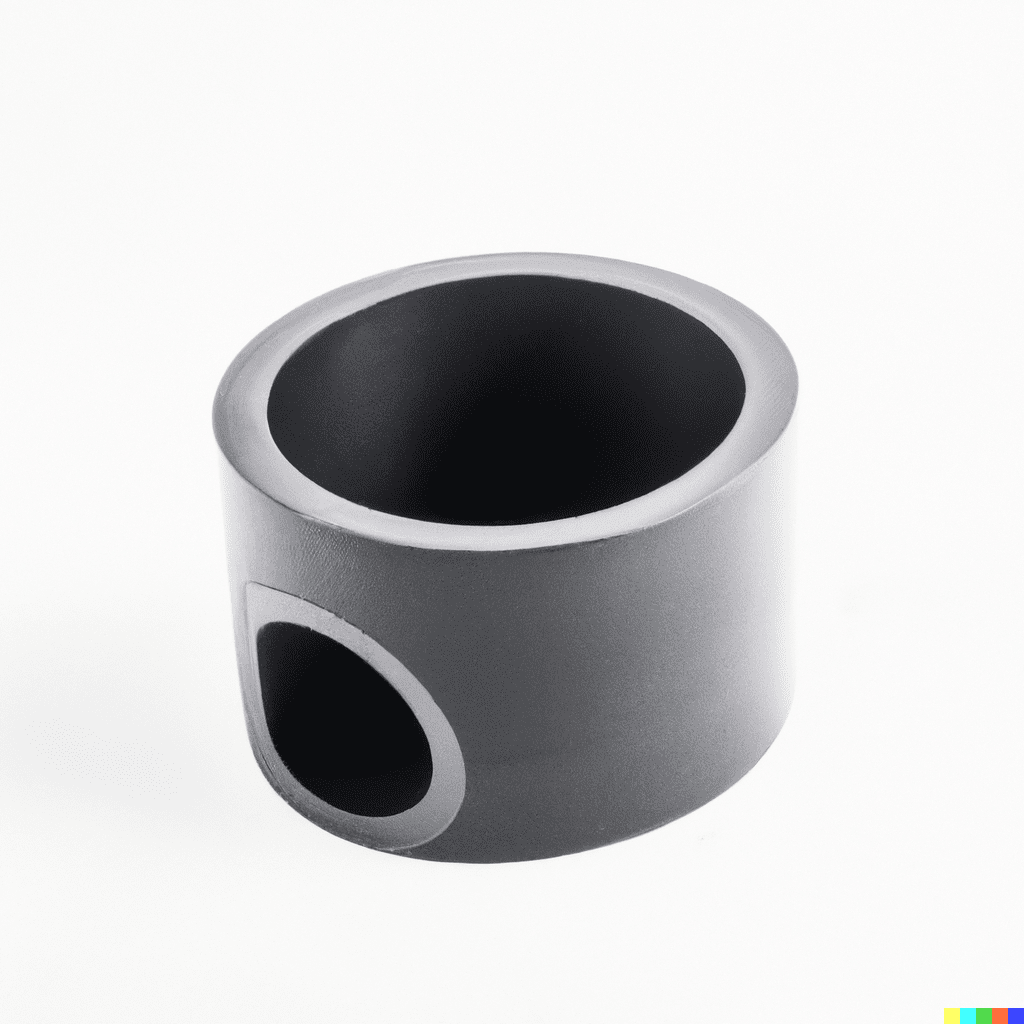

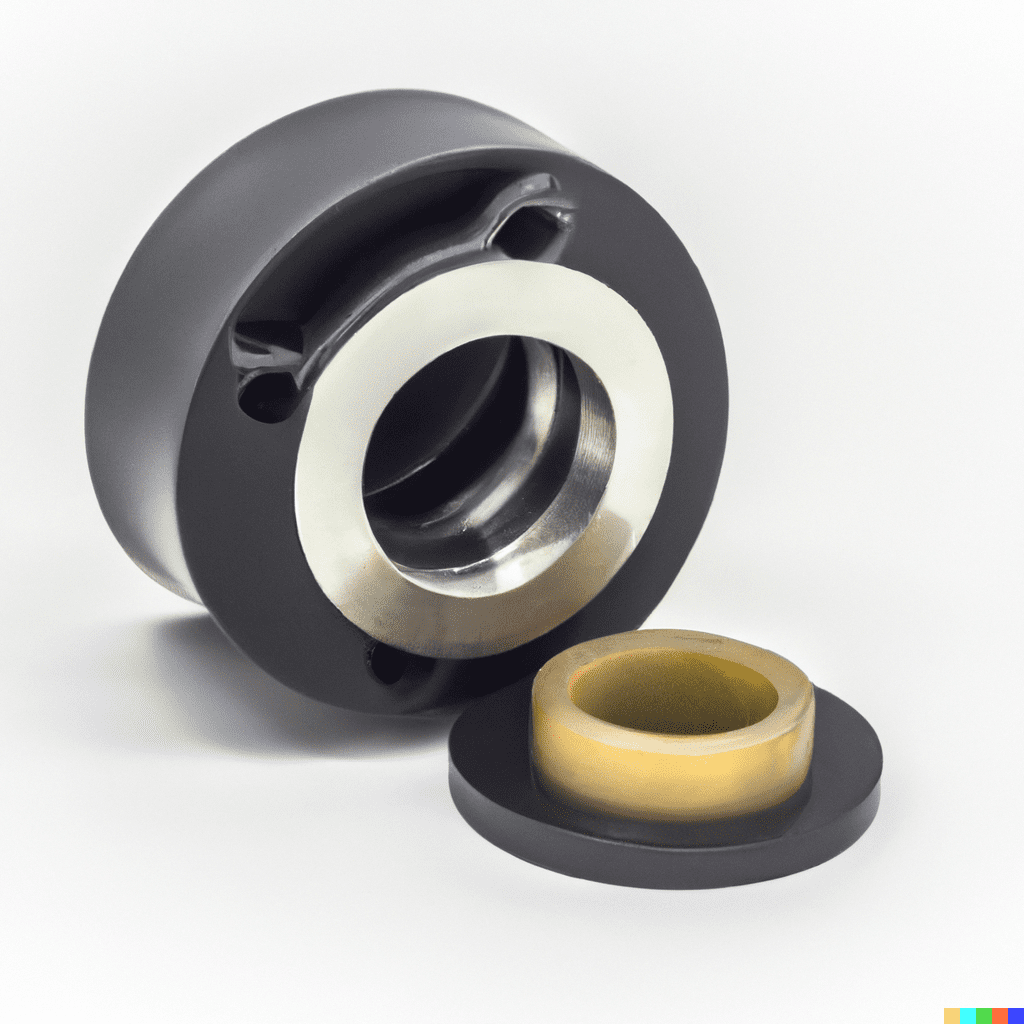

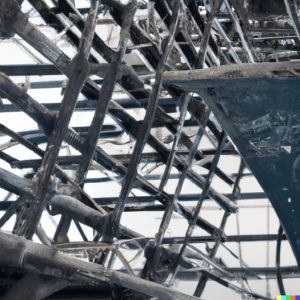

Tensile Strength: 60-80 MPa

Impact Strength: 20-40 kJ/m²

Density: 1.03 g/cm³

Melting Point: 220-260°C |

Various colors available

Low density

Good dimensional stability

|

Resistant to many chemicals and oils

|

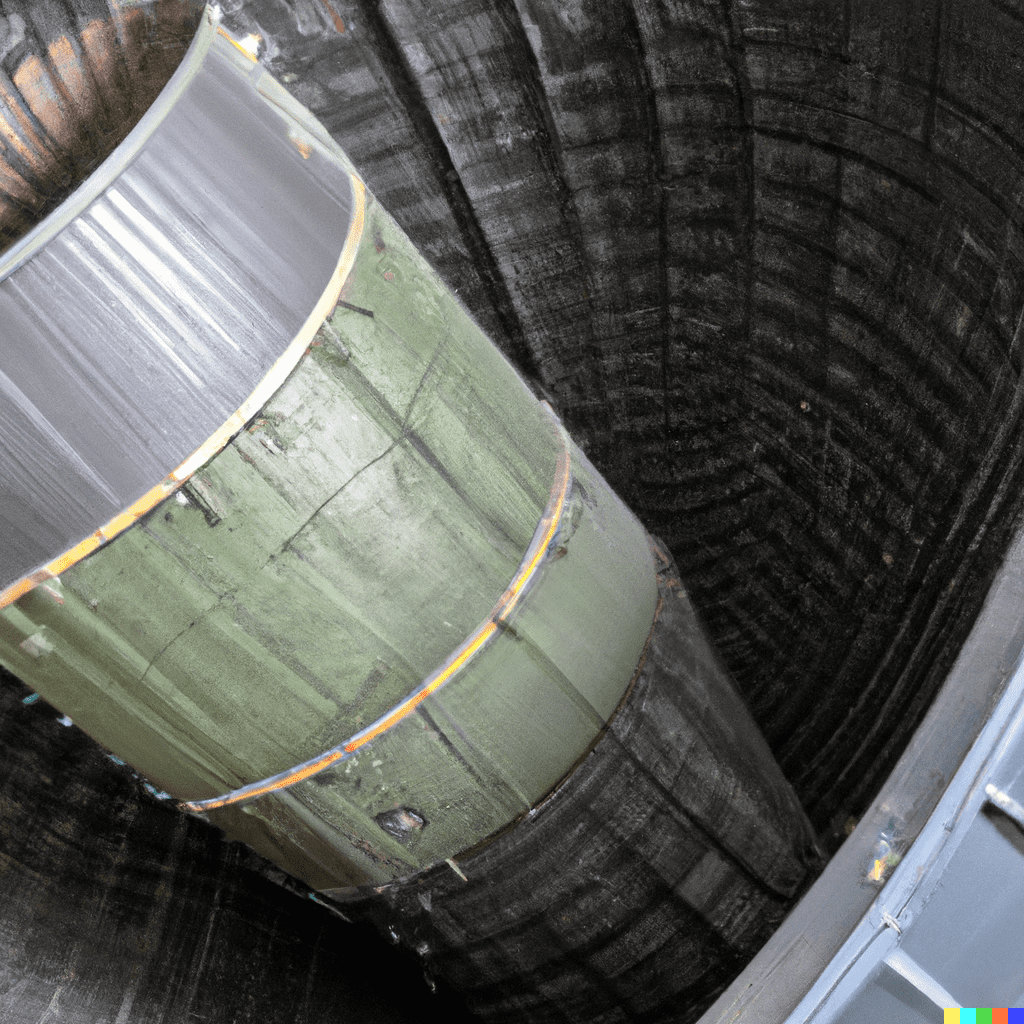

High strength and impact resistance

Lightweight

|

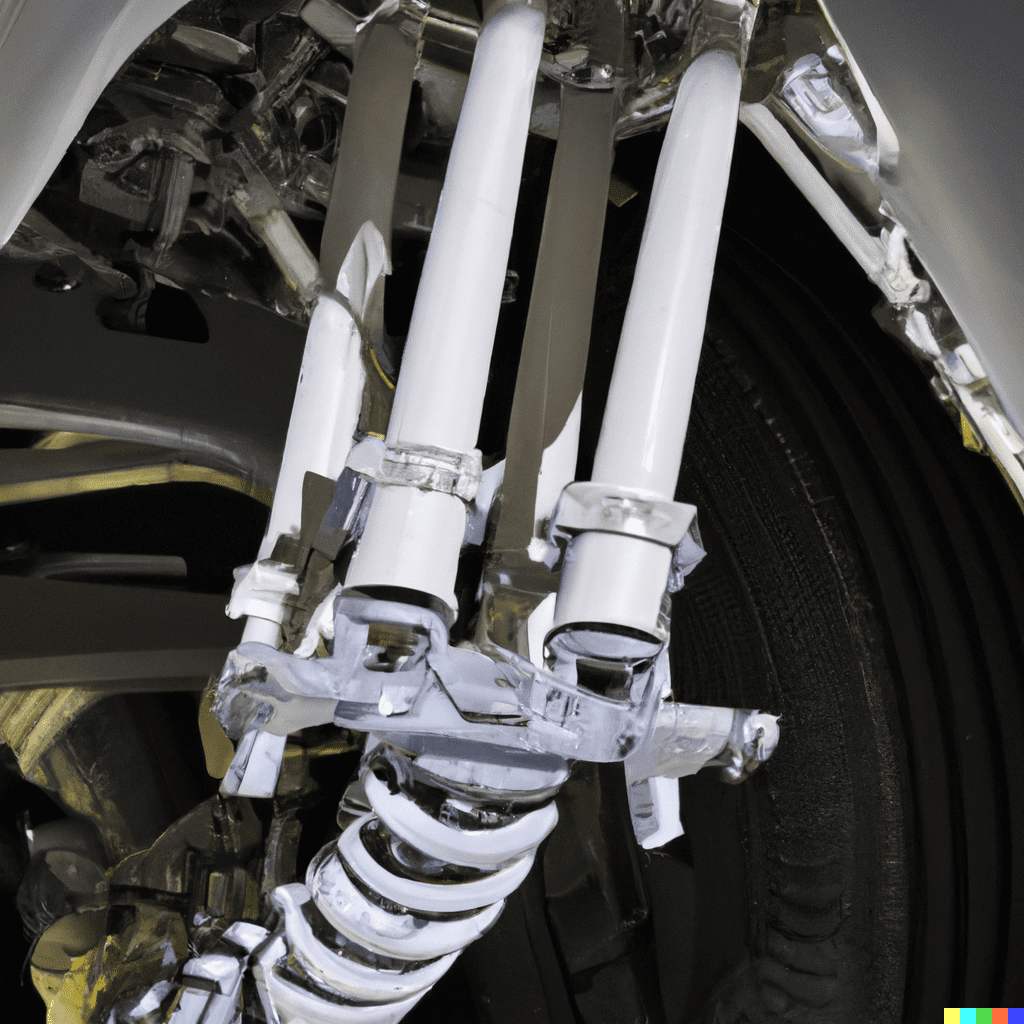

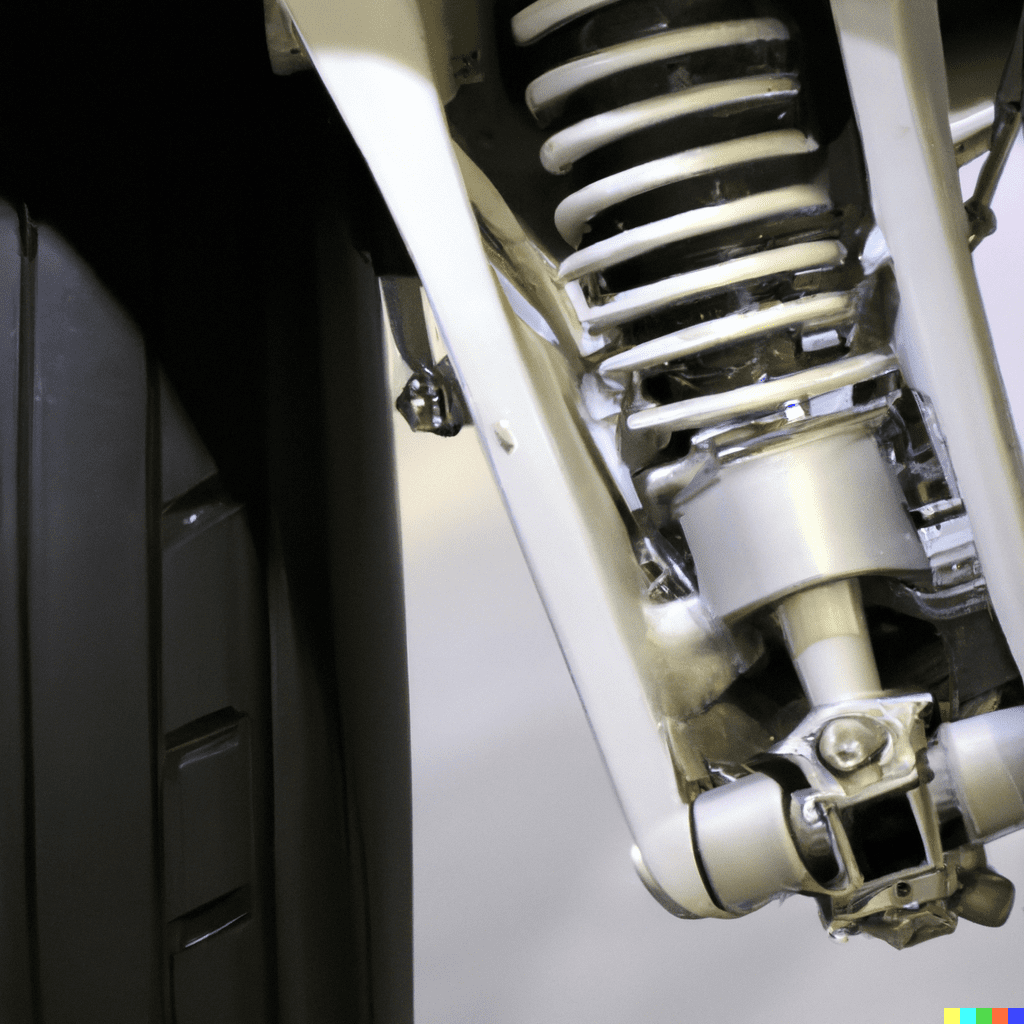

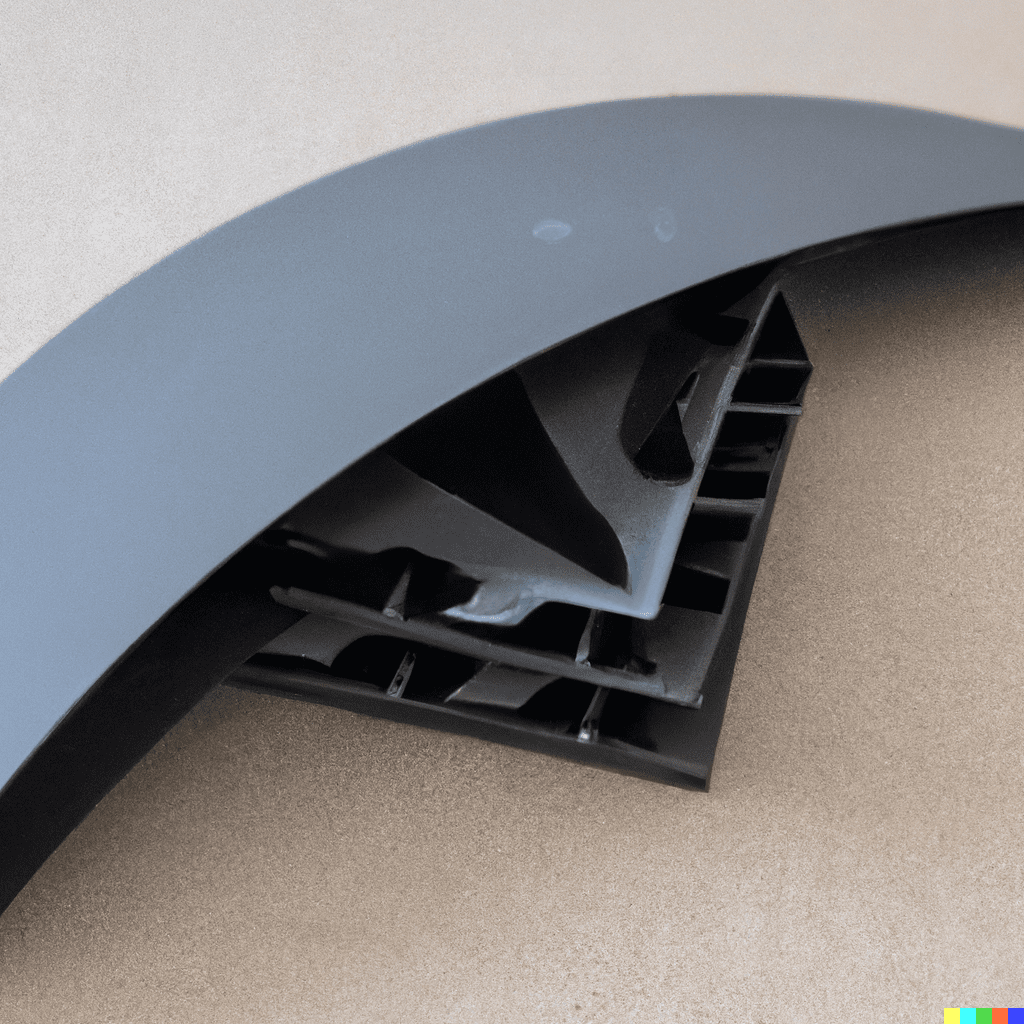

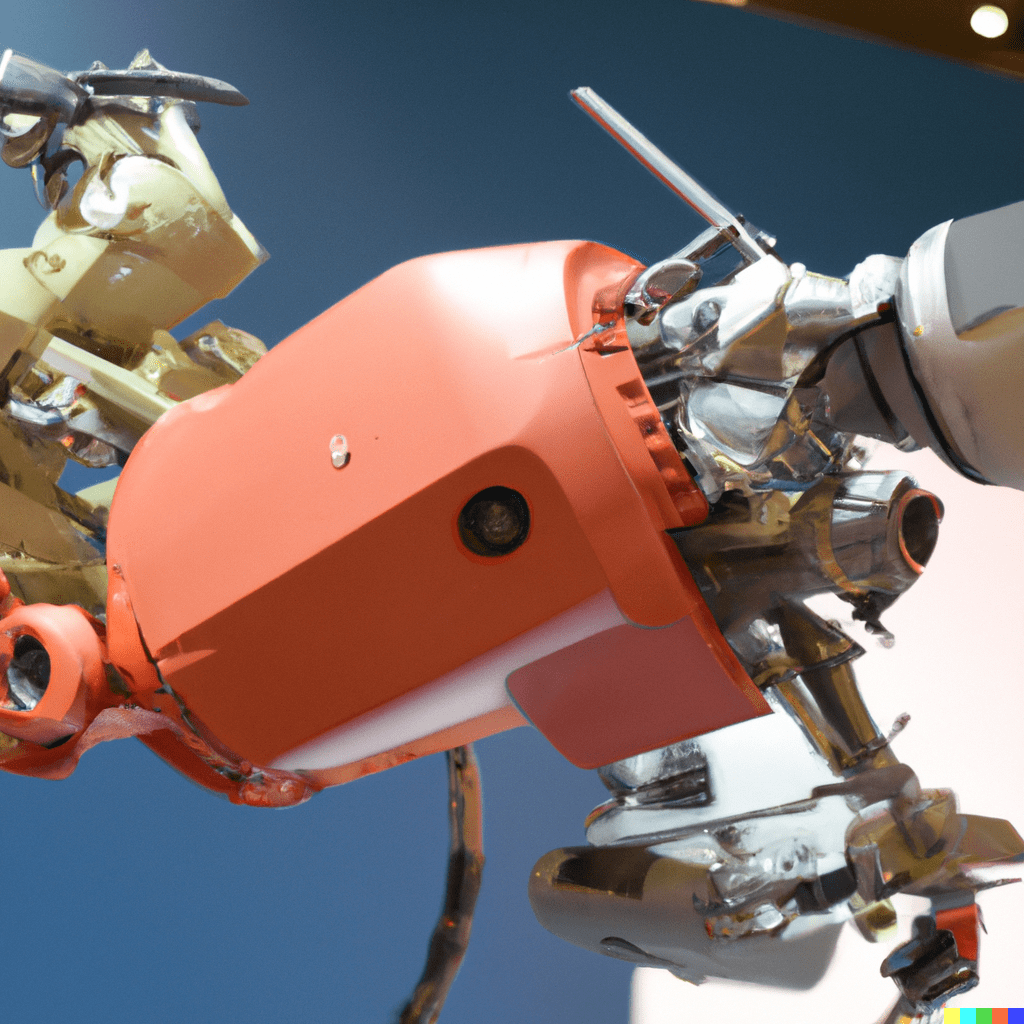

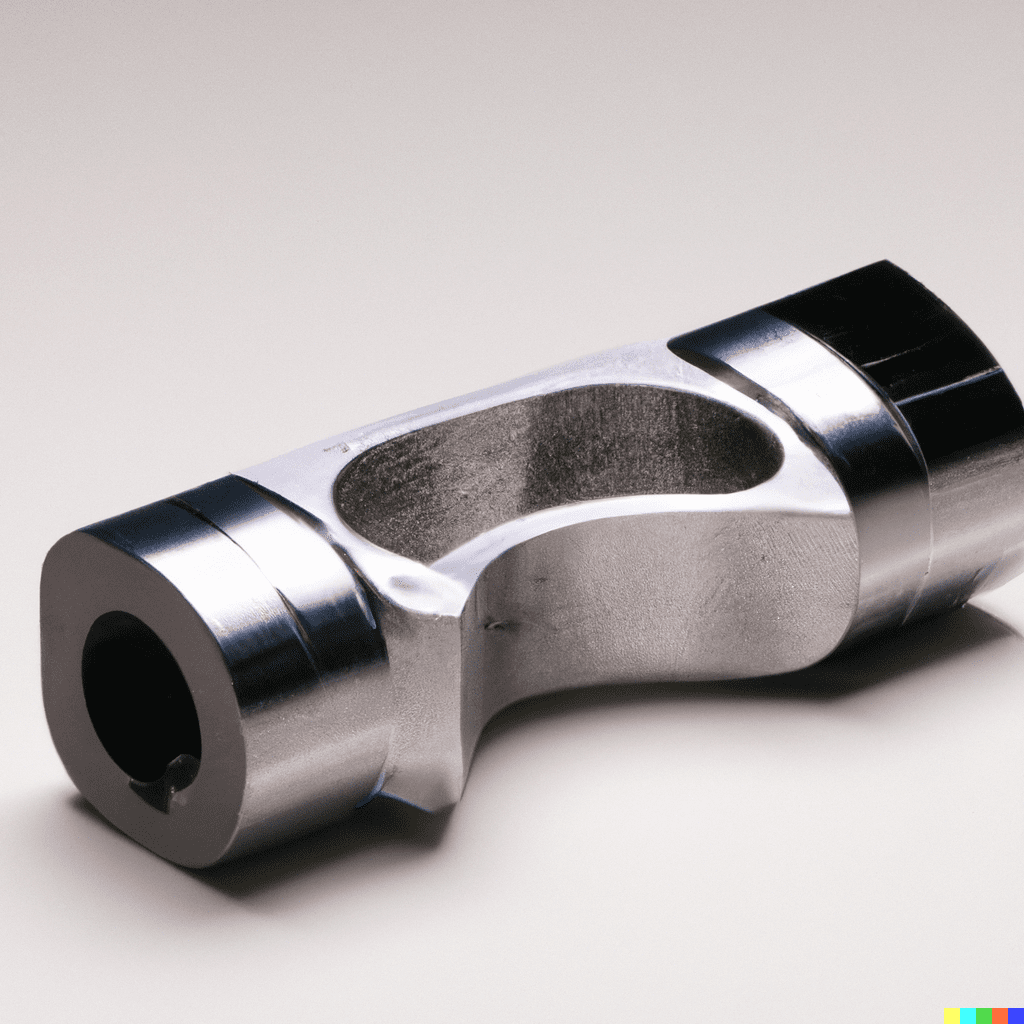

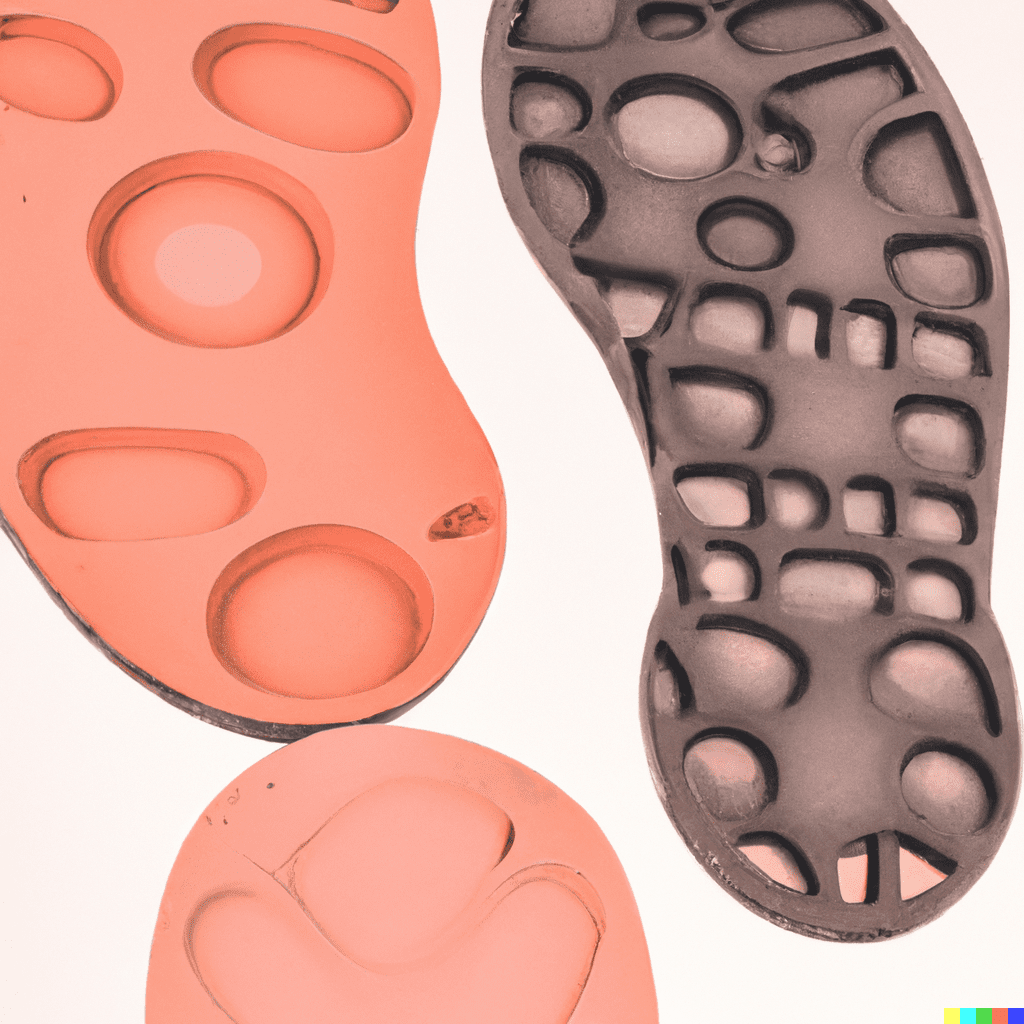

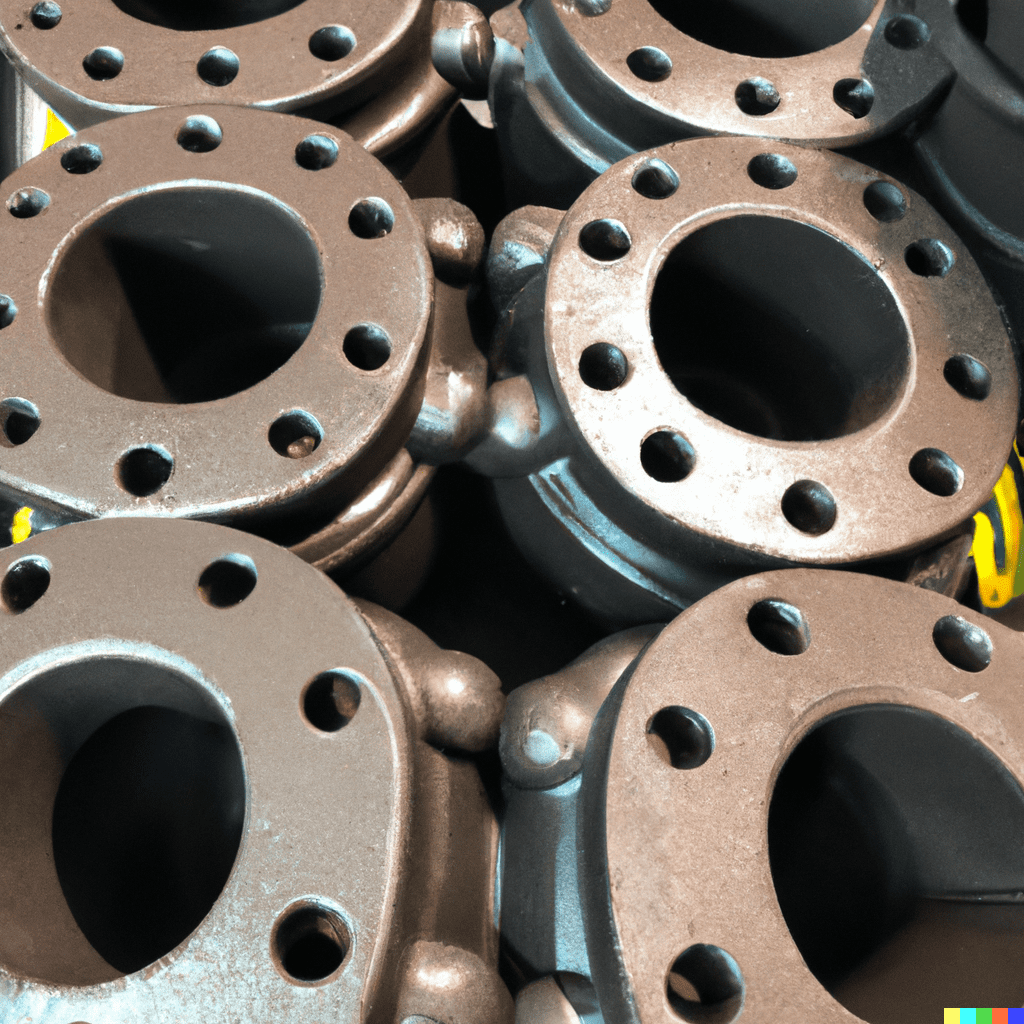

Automotive: Bumpers, Aerospace and Defense: Structural components |

|

|

|

|

|

|

|

|

|

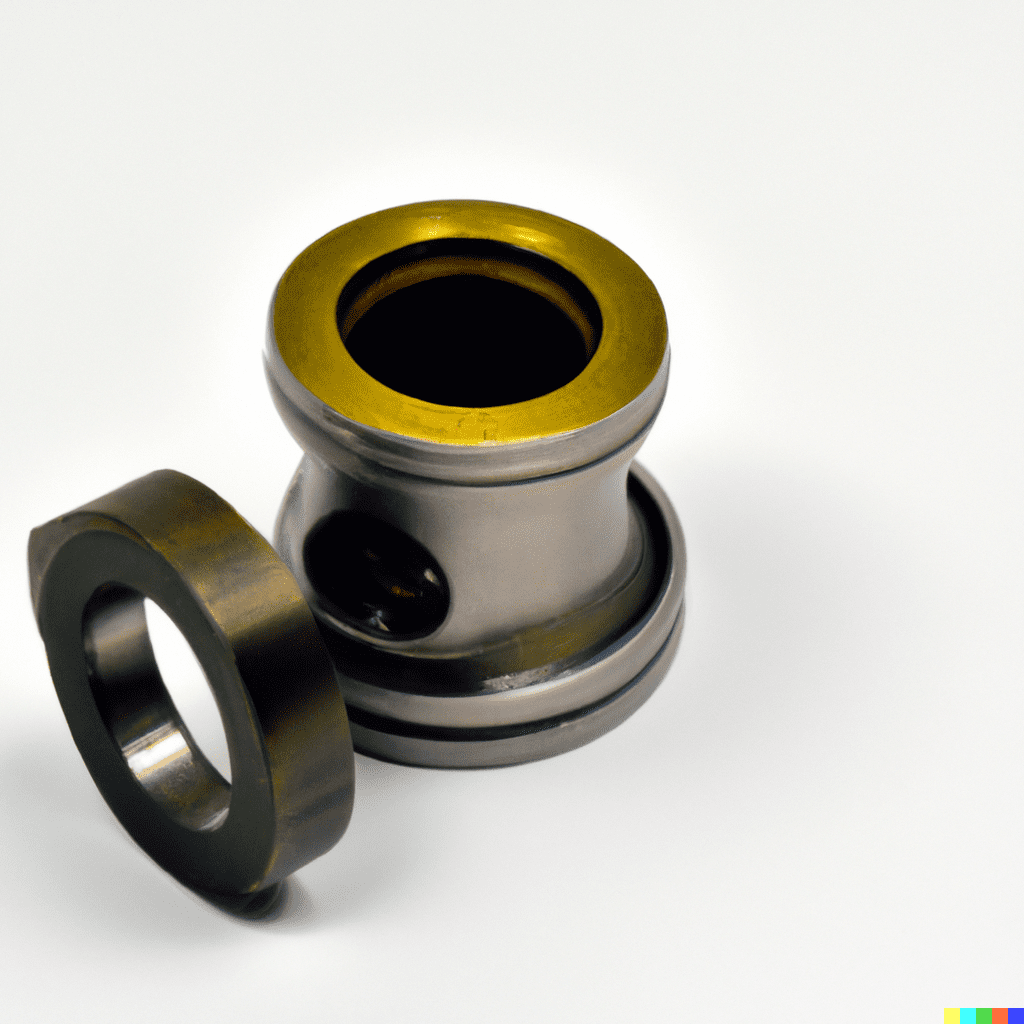

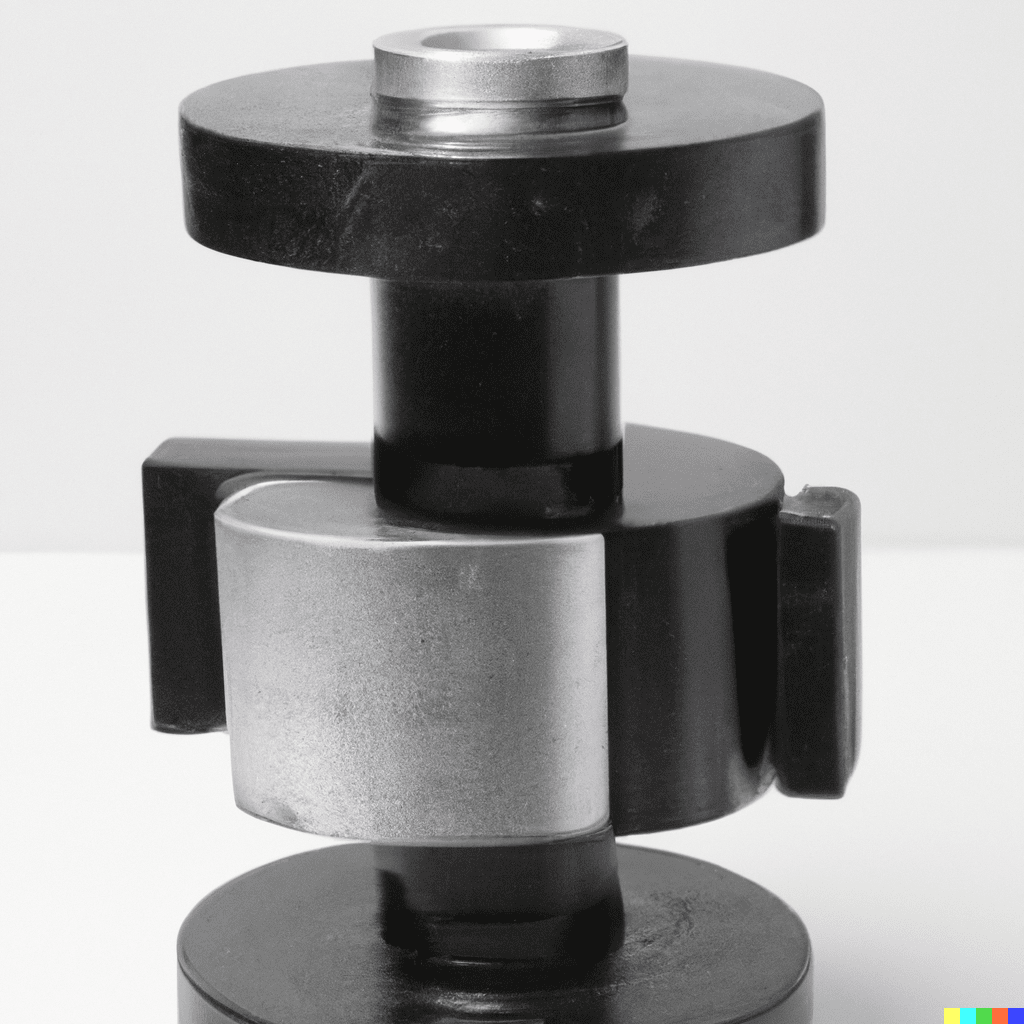

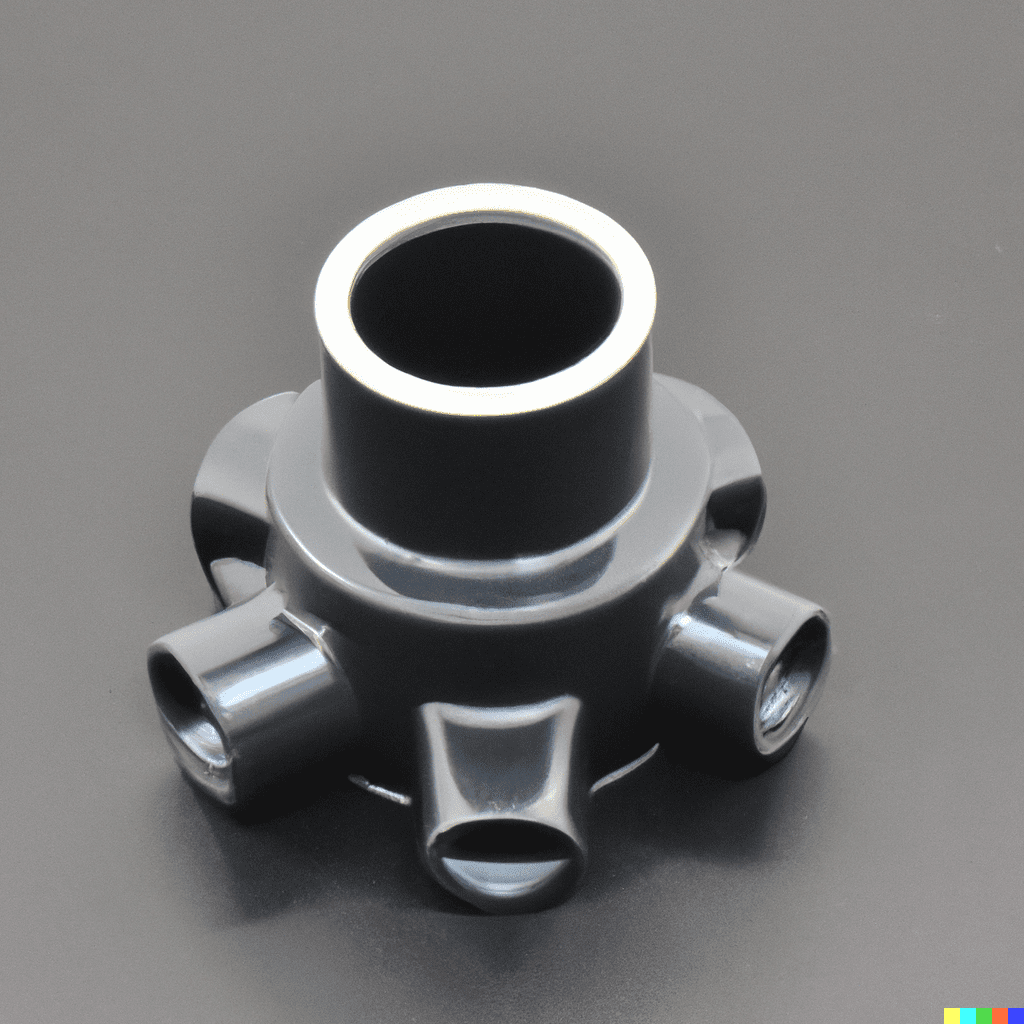

Tensile Strength: 40-60 MPa

Impact Strength: 5-20 kJ/m²

Density: 1.03 g/cm³

Melting Point: 220-260°C

|

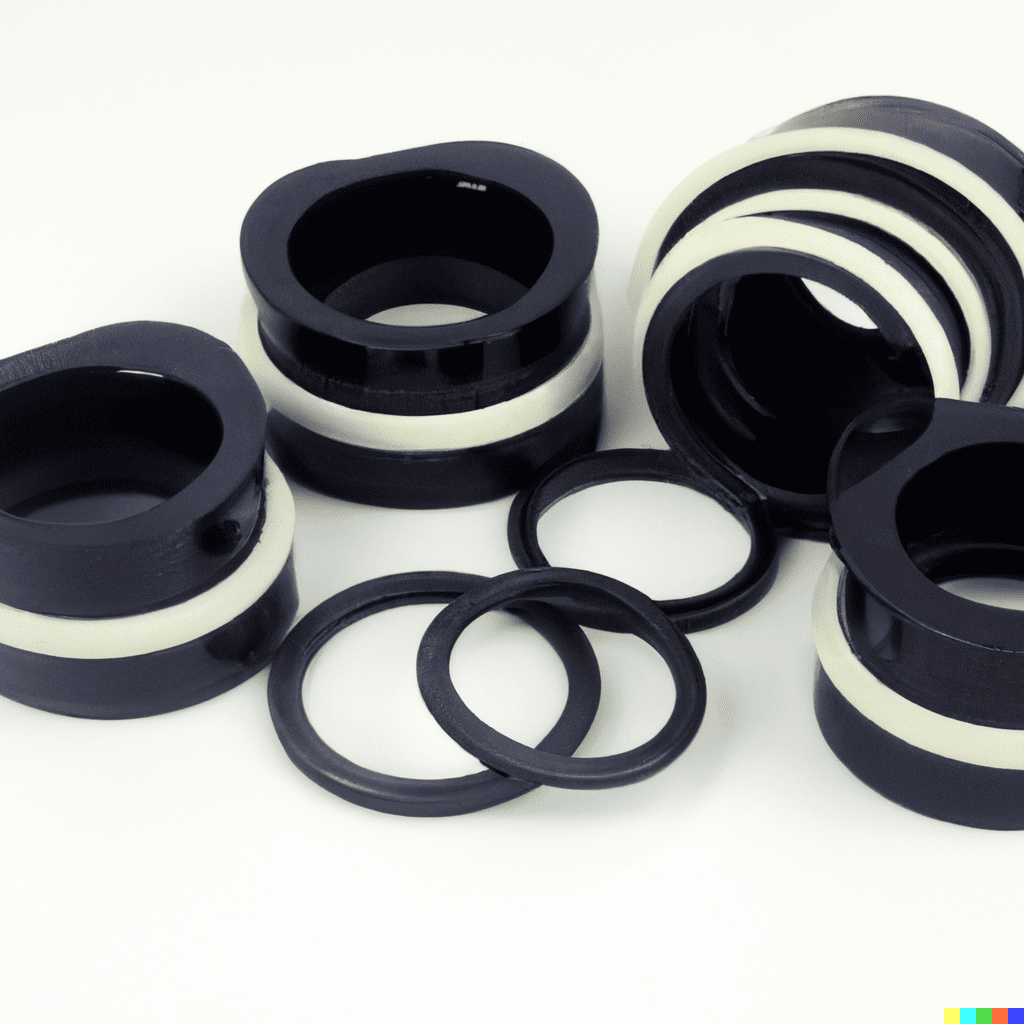

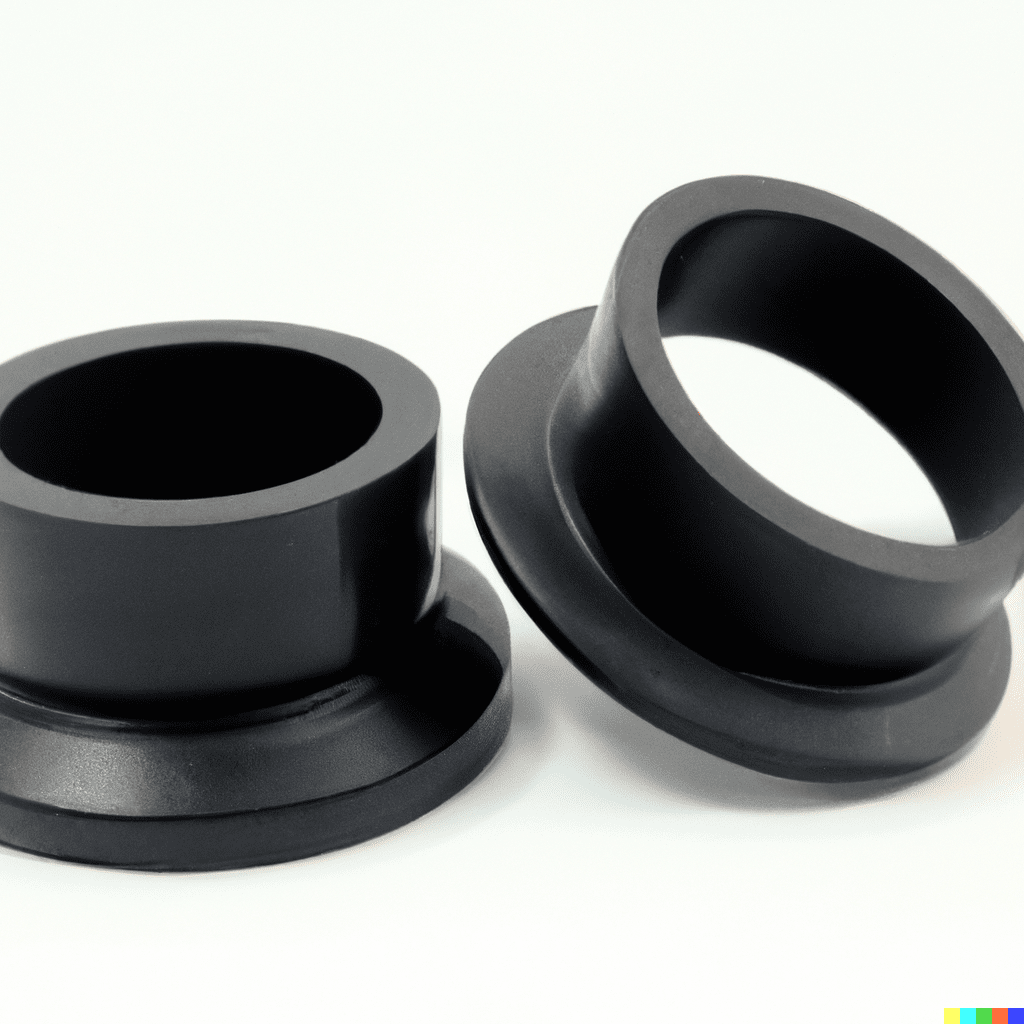

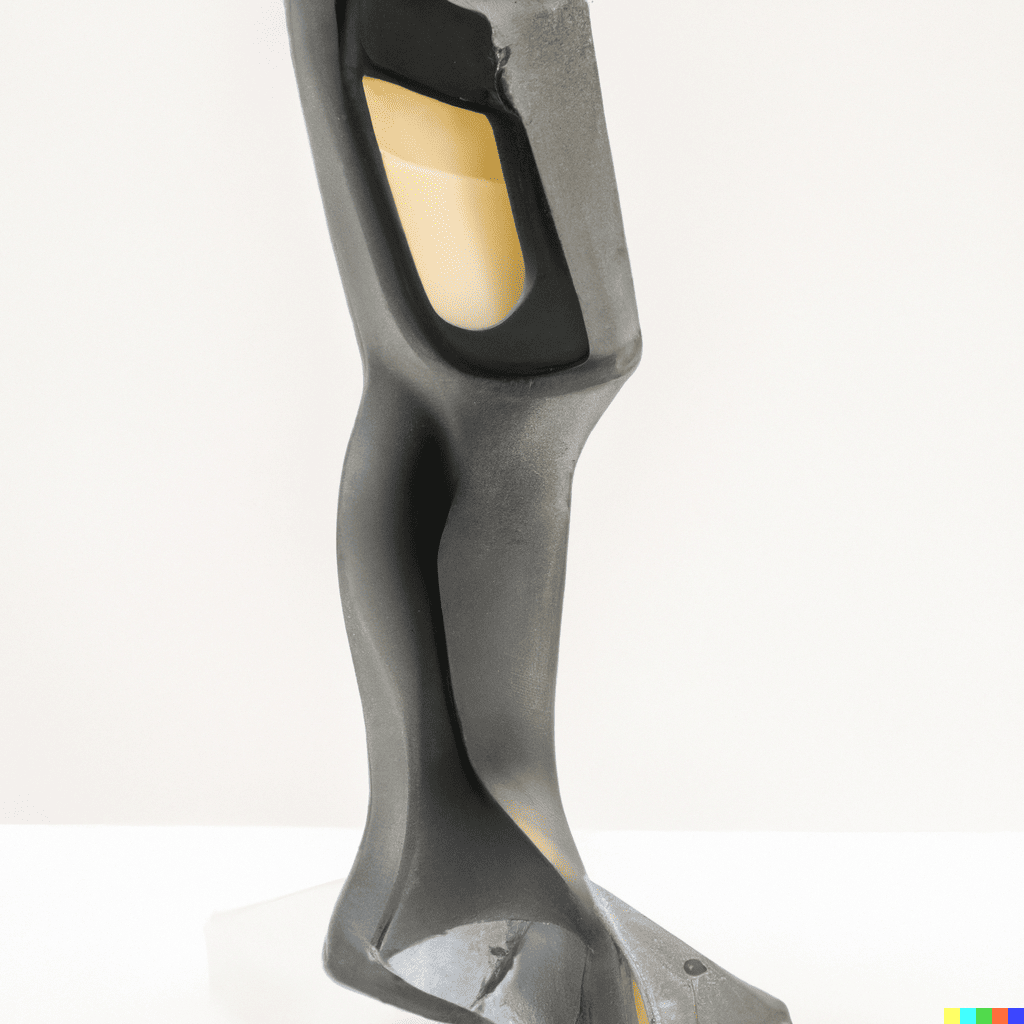

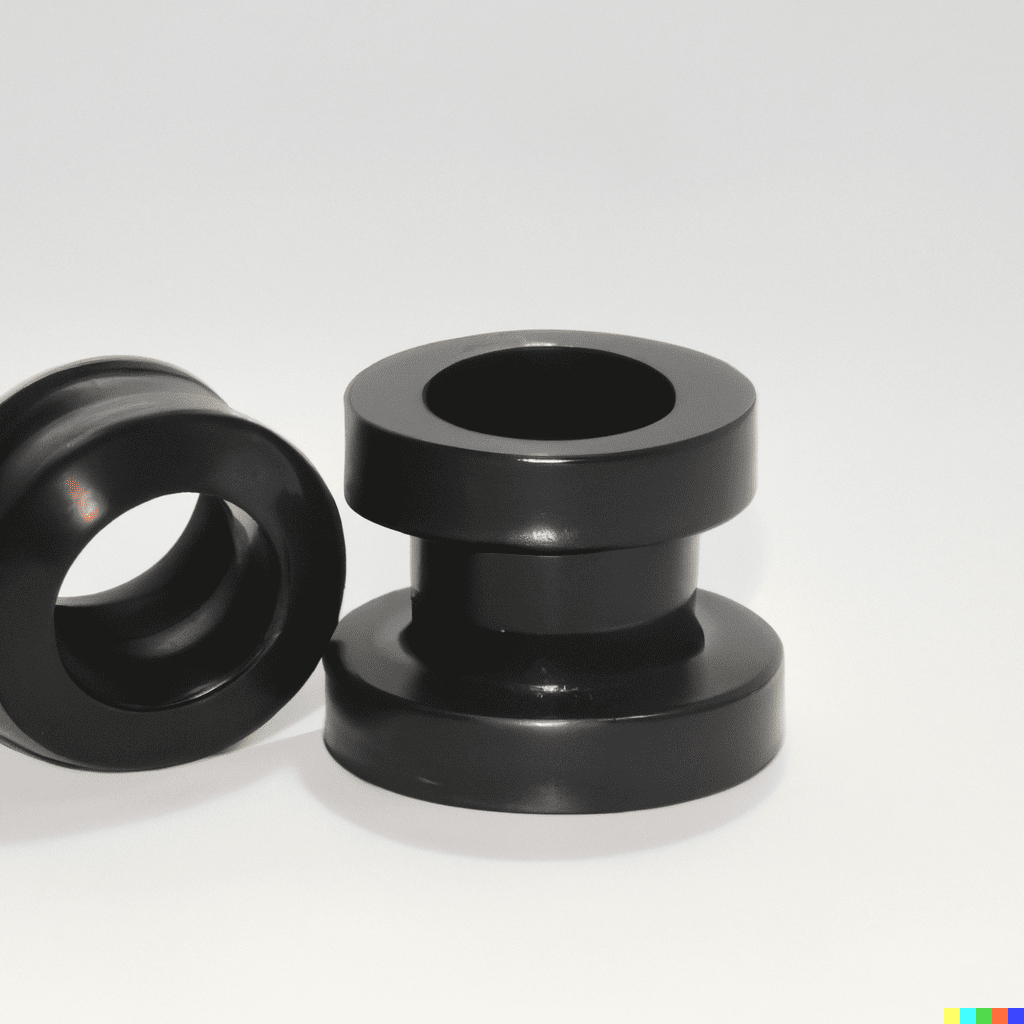

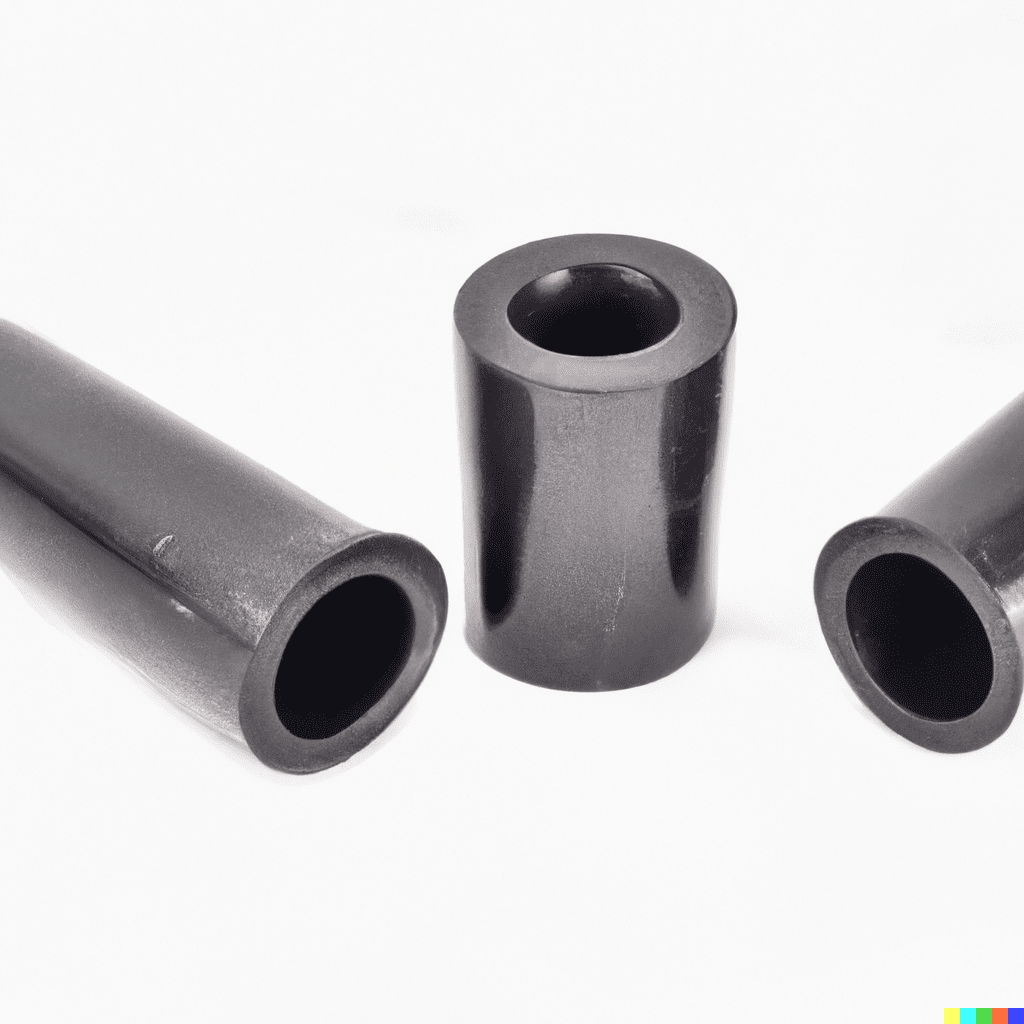

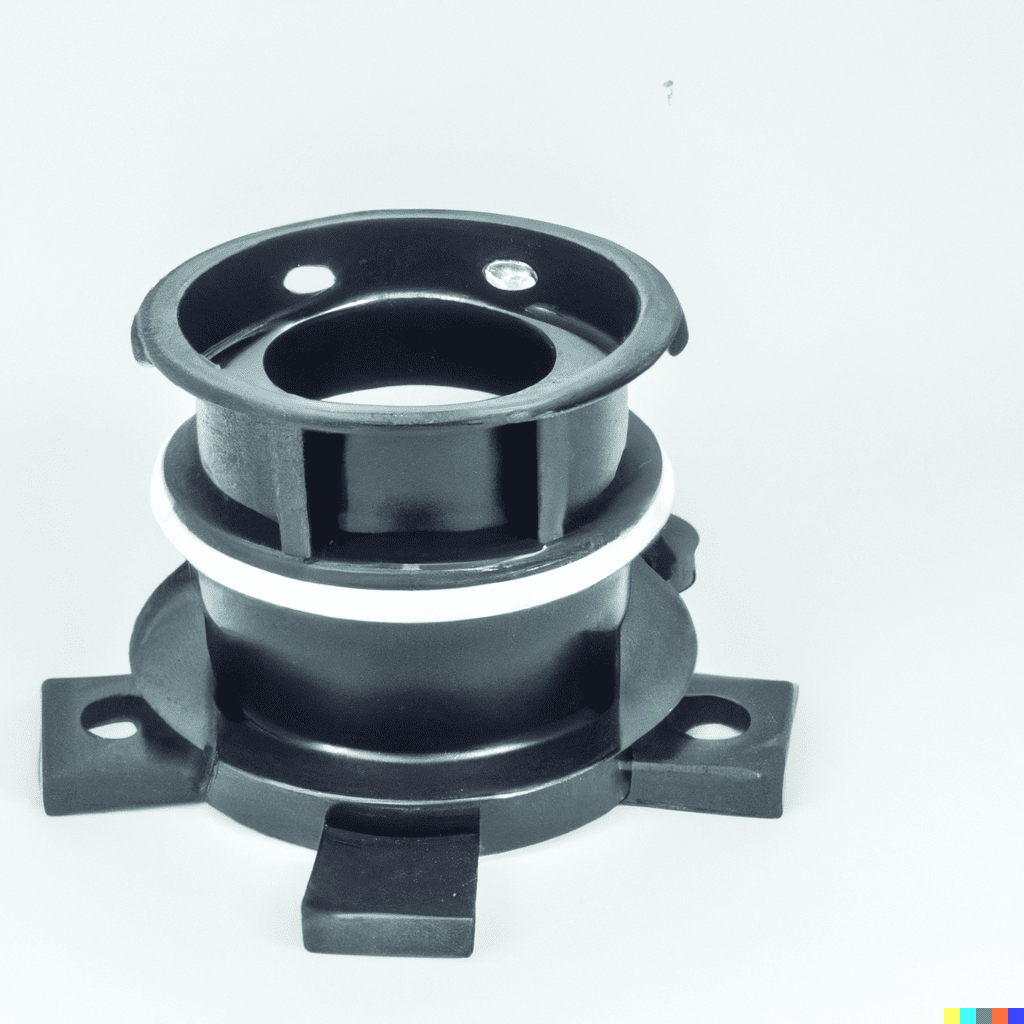

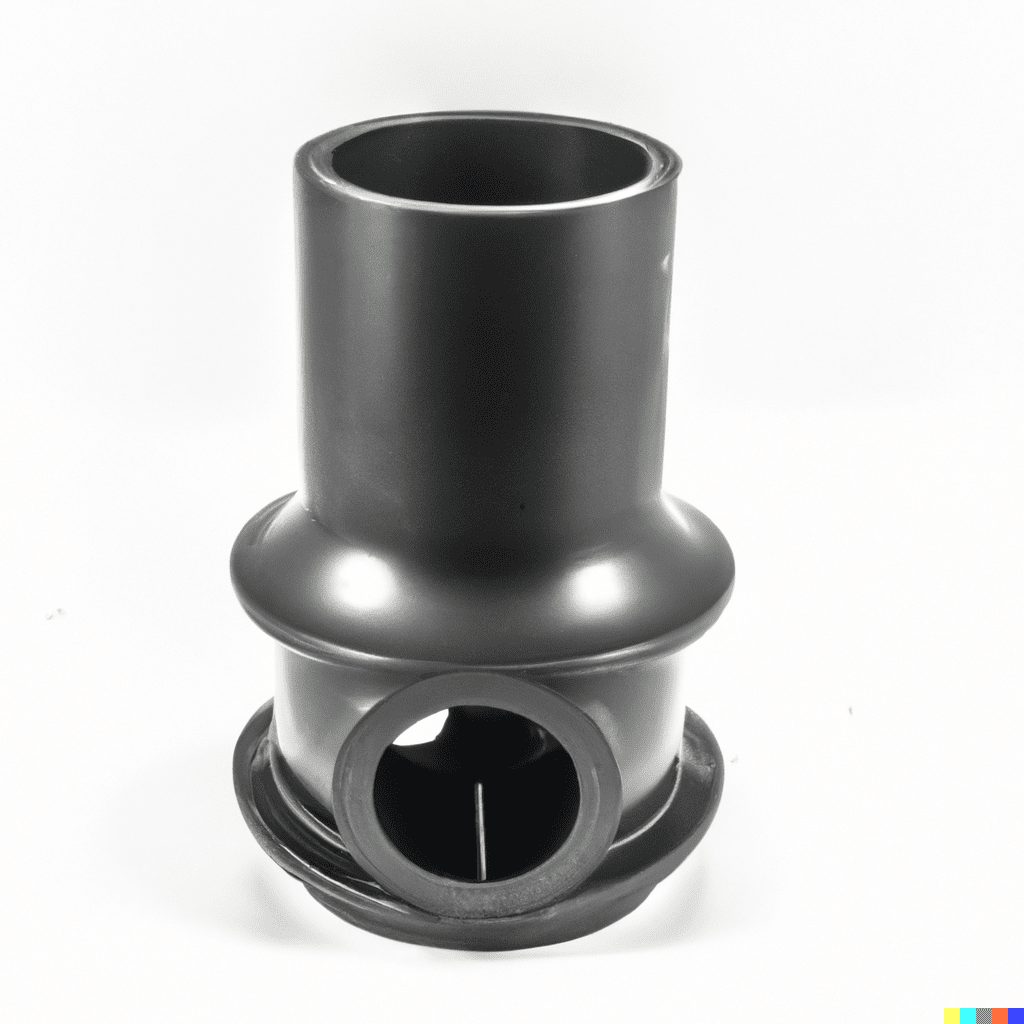

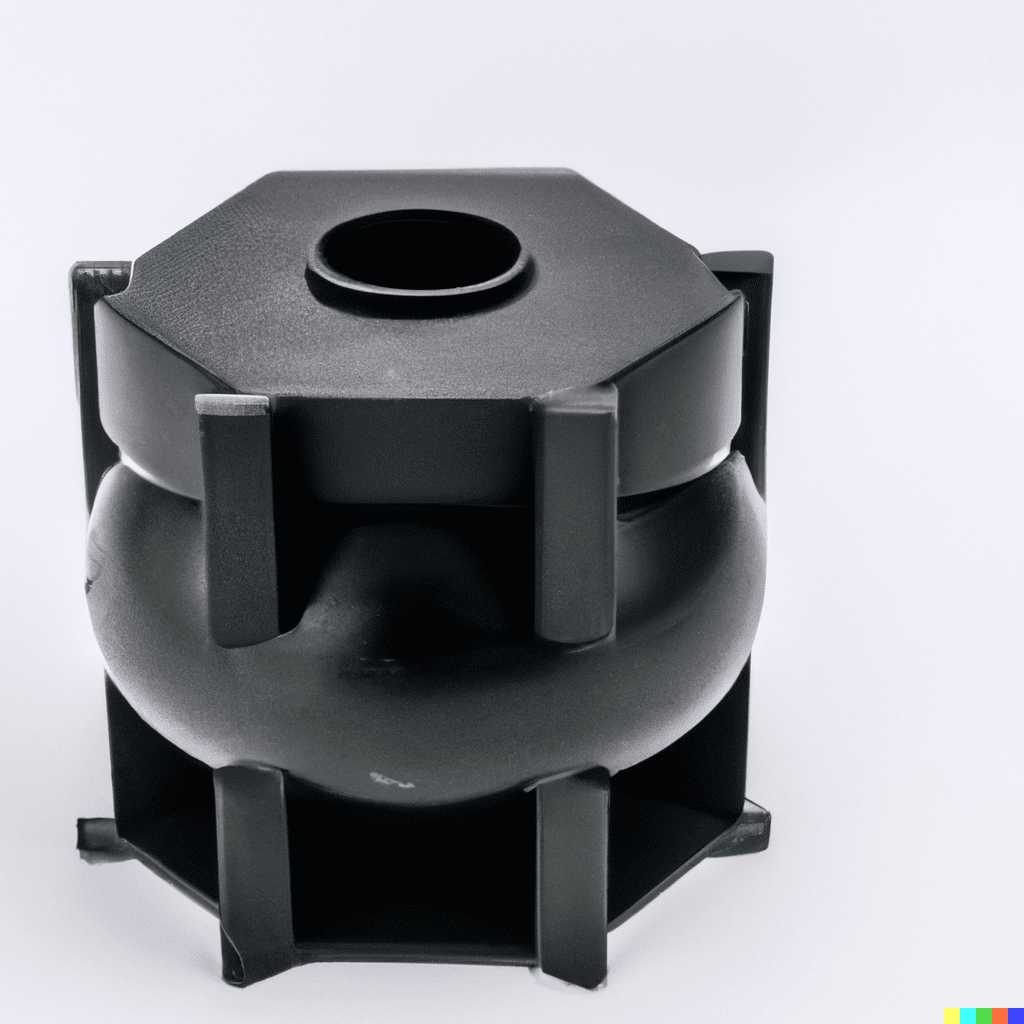

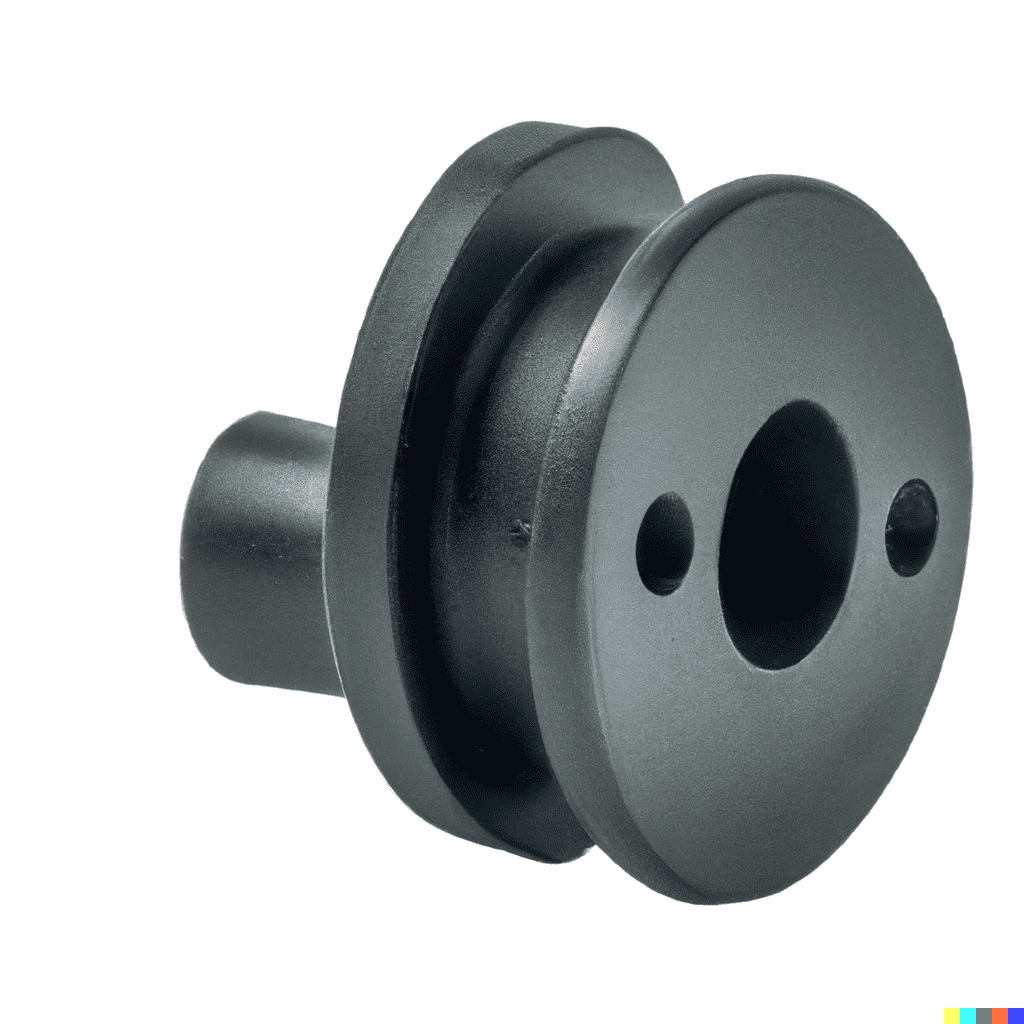

Black color

Low density

Good dimensional stability

|

Resistant to many chemicals and oils

|

Black appearance

Lightweight -

Durable |

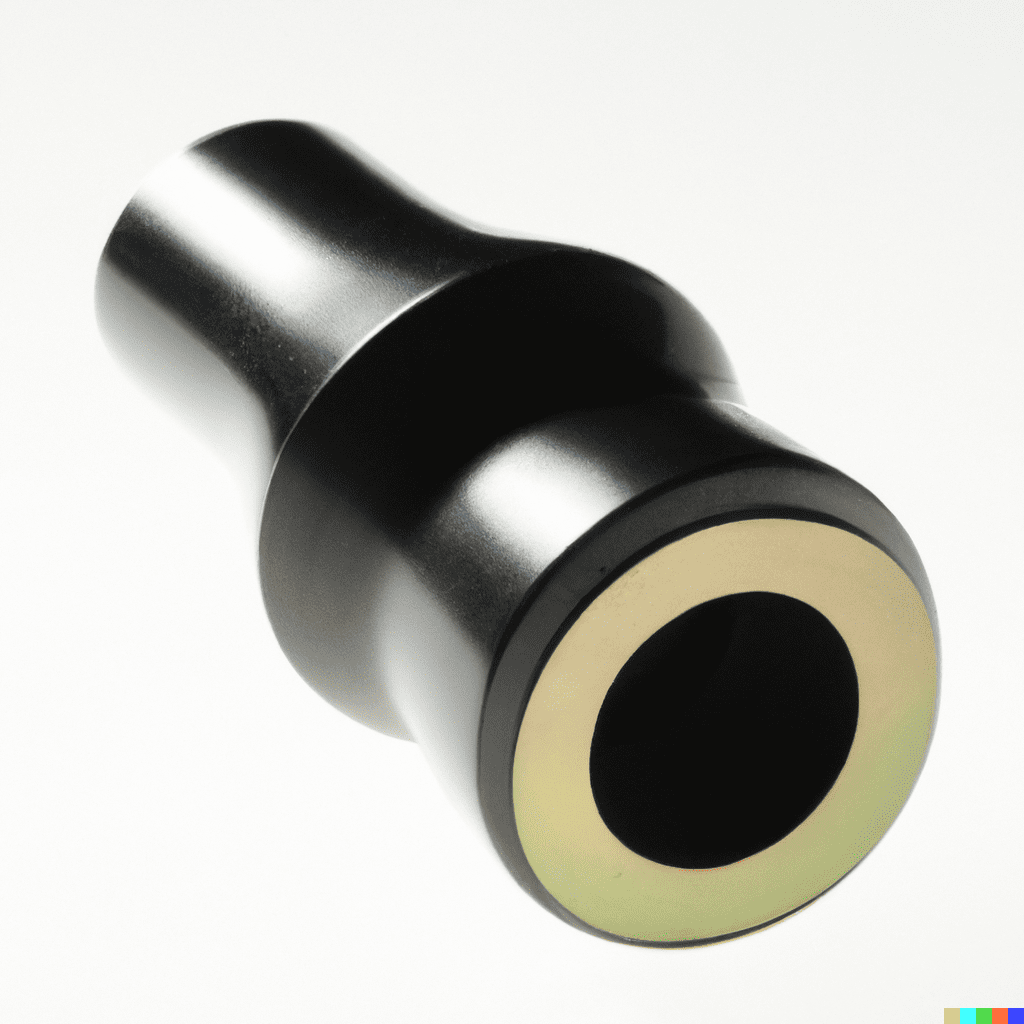

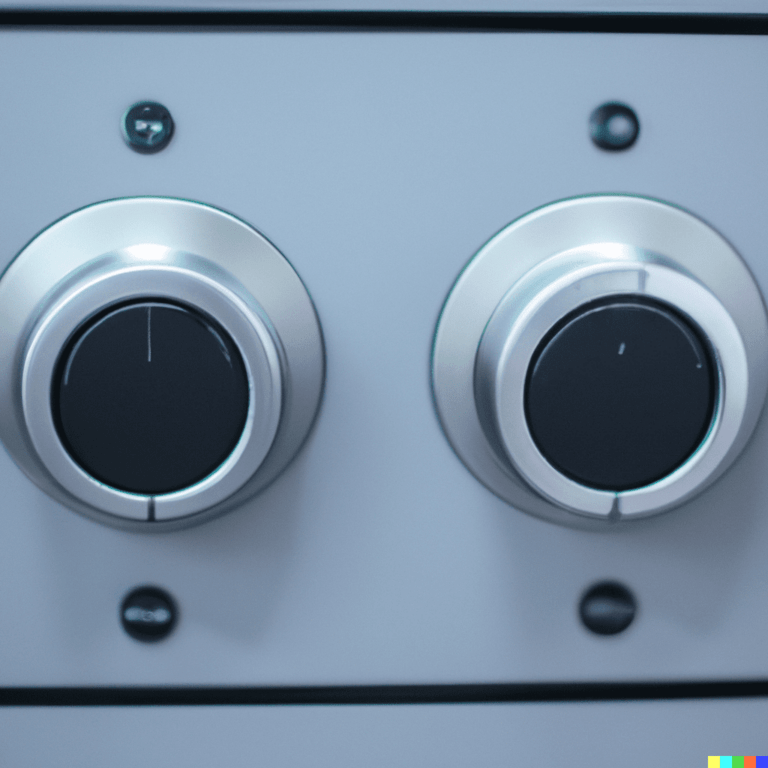

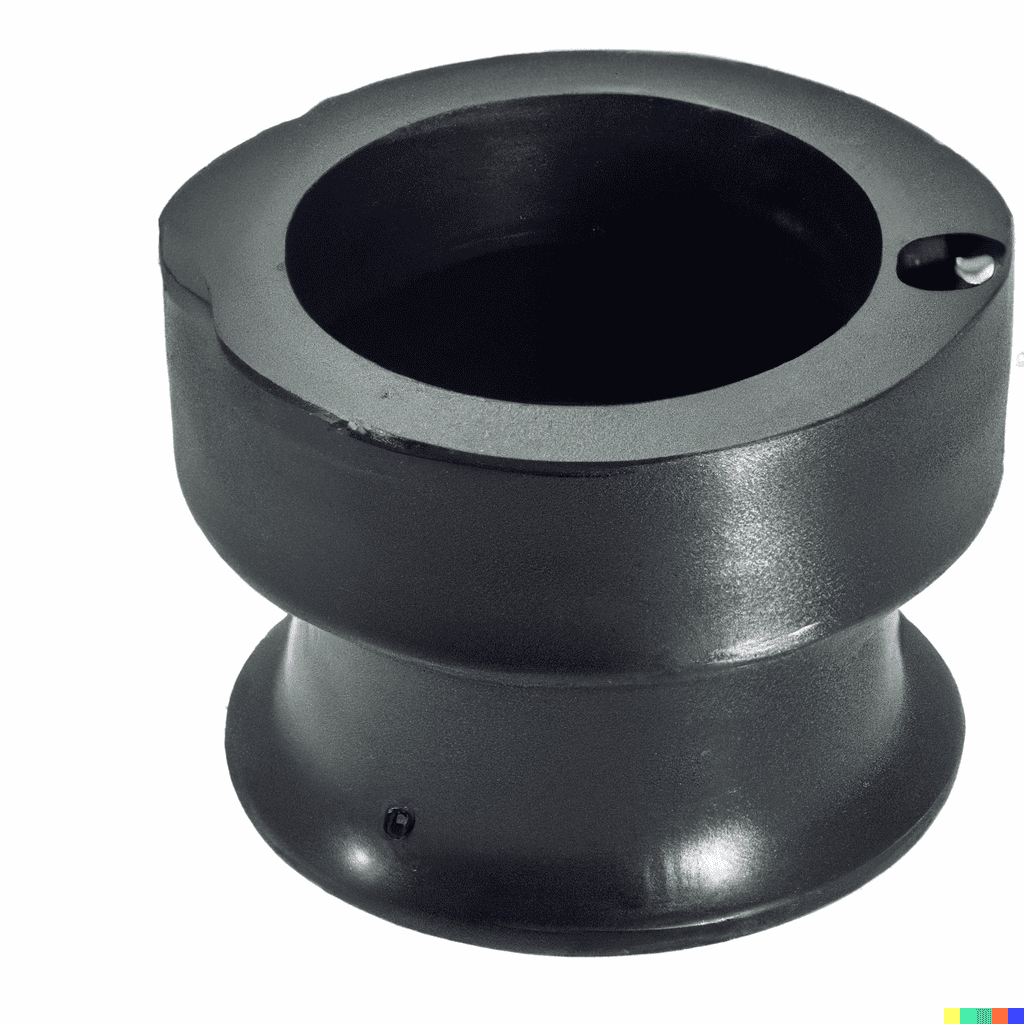

Consumer Products: Electronics casings, automotive interior parts |

|

|

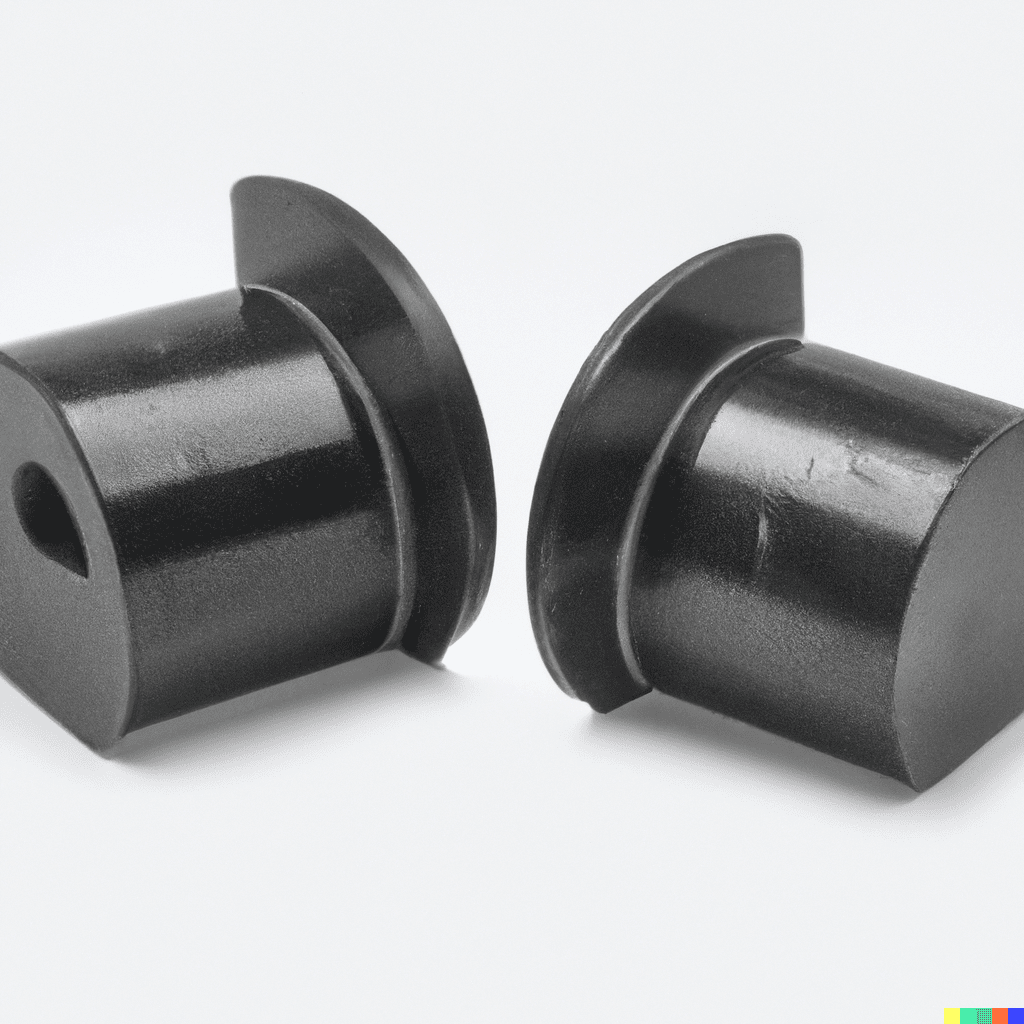

Tensile Strength: 40-60 MPa

Impact Strength: 5-20 kJ/m²

Density: 1.03 g/cm³

Melting Point: 220-260°C |

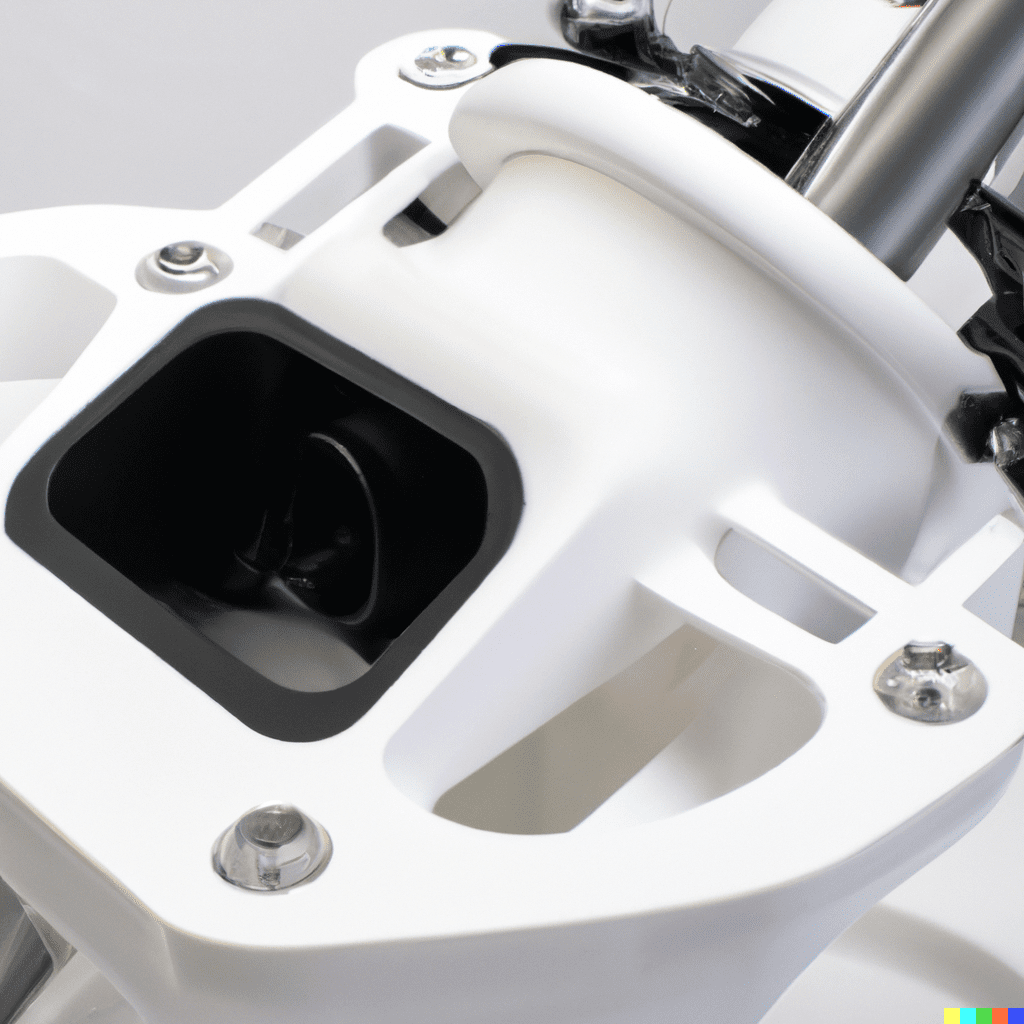

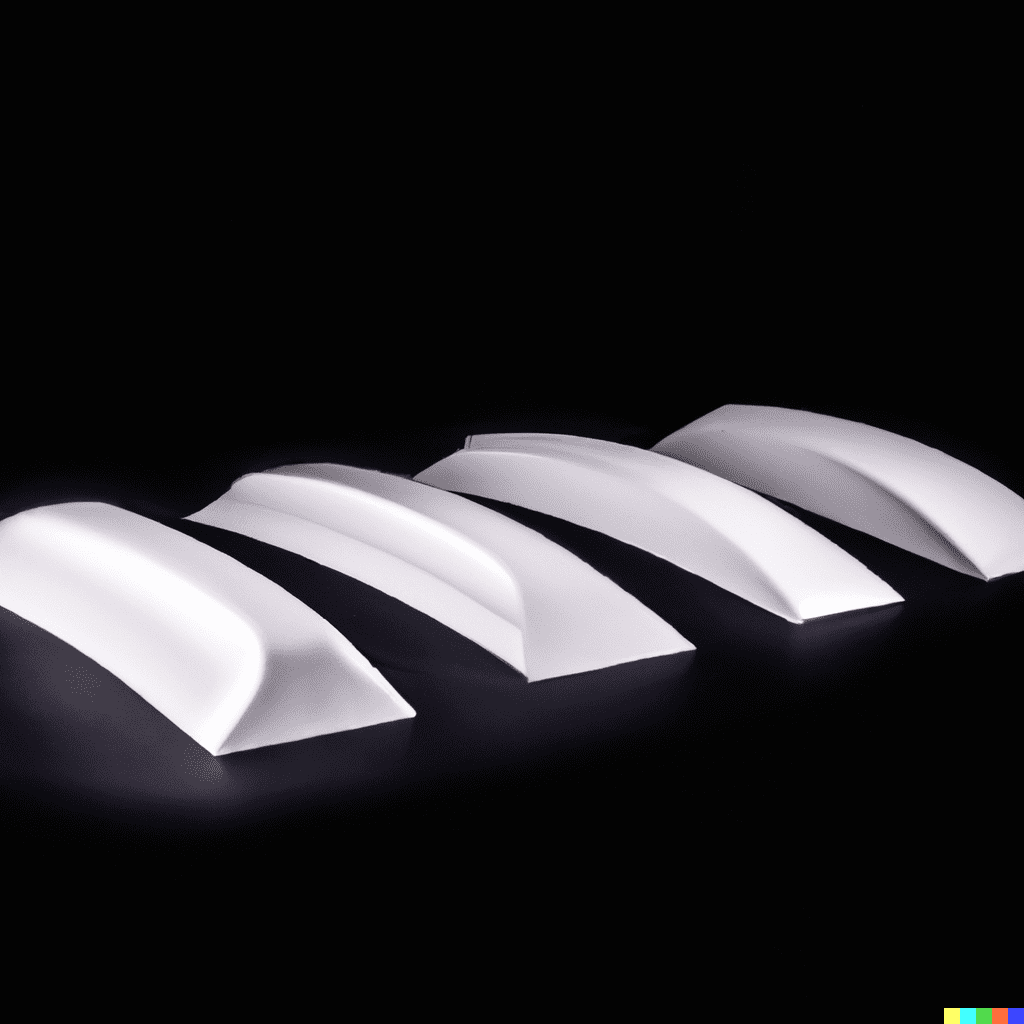

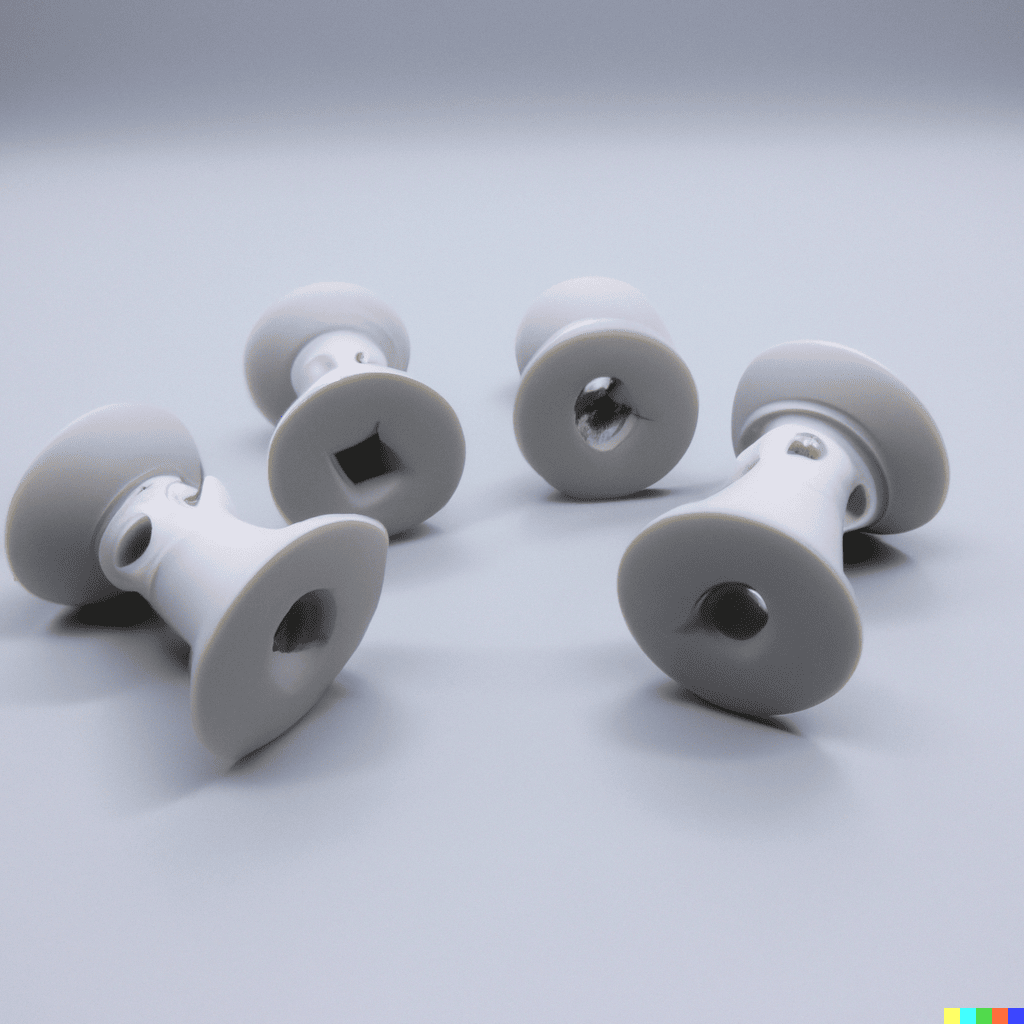

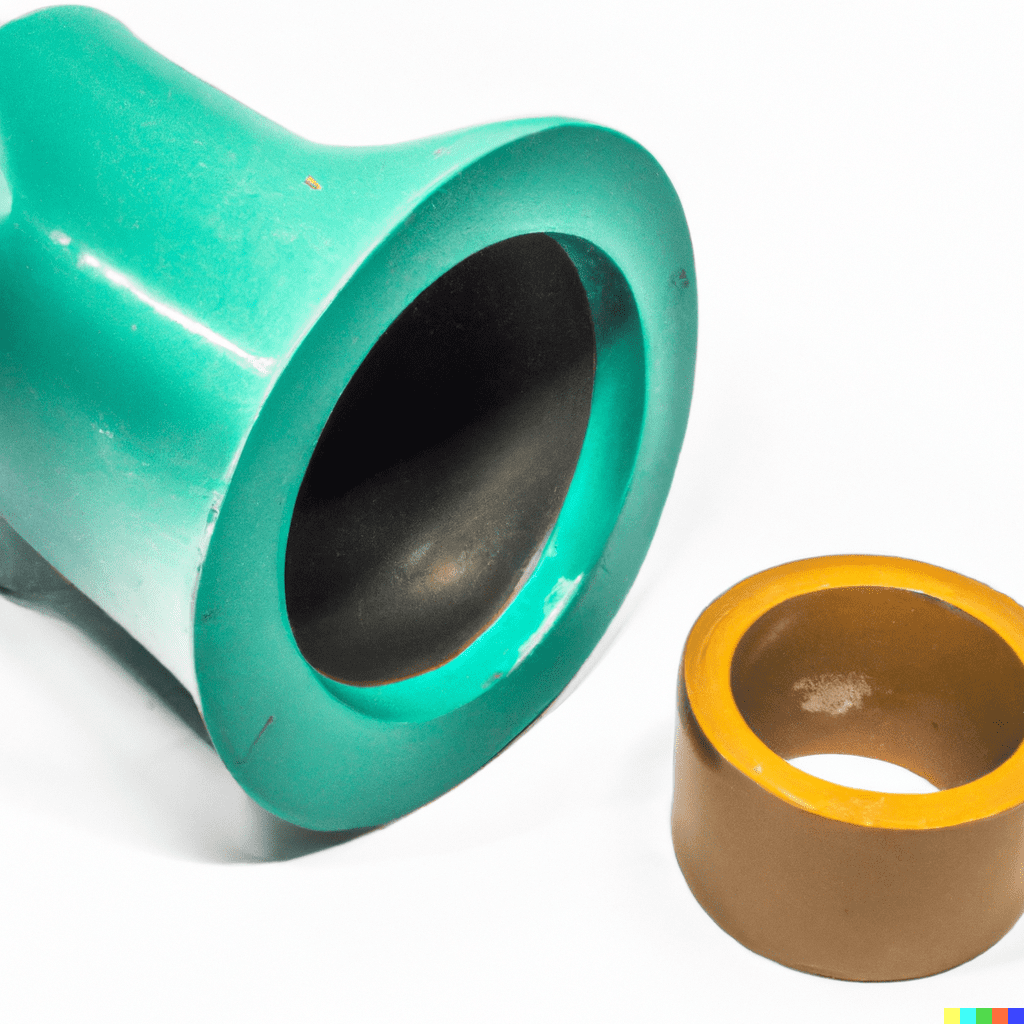

White color

Low density

Good dimensional stability

|

Resistant to many chemicals and oils

|

White appearance

Lightweight

Durable

|

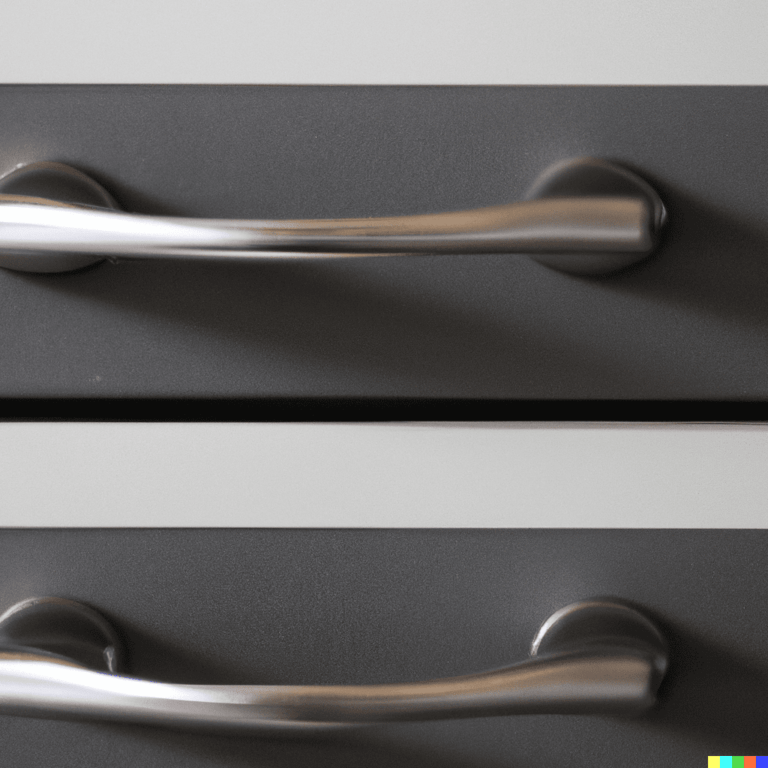

Consumer Products: Electronics casings, toys, kitchen appliances |

|

|

|

|

Resistant to diluted acids, alkalis |

High strength, versatility,

cost-effective |

Automotive, Consumer Products |

|

|

|

|

|

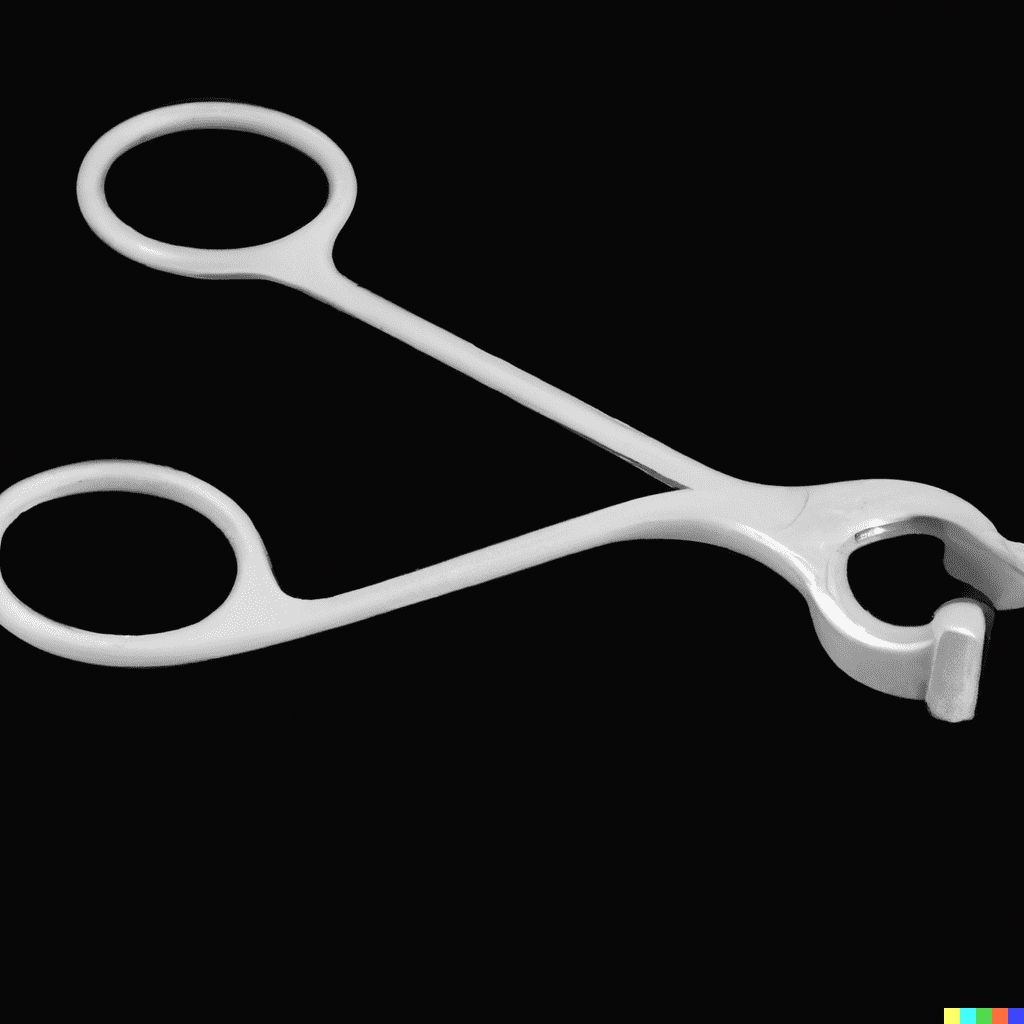

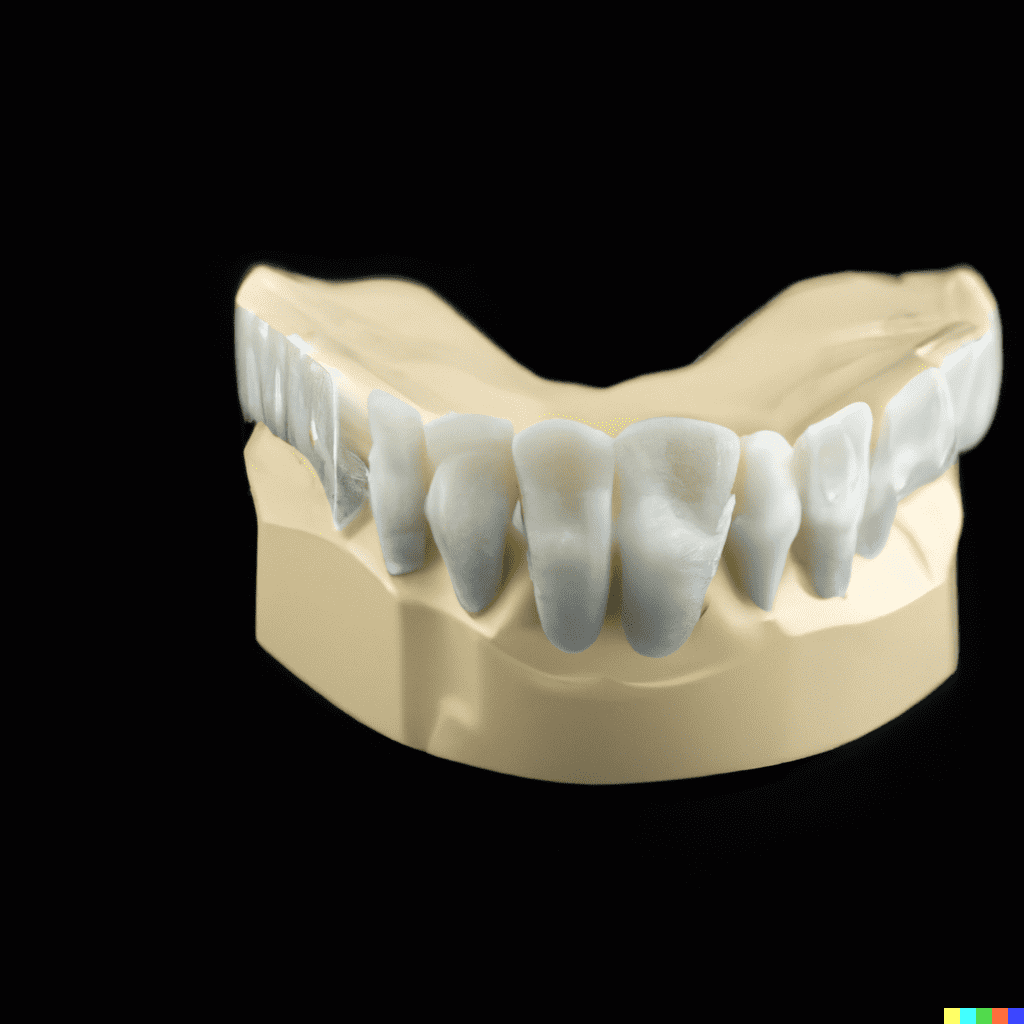

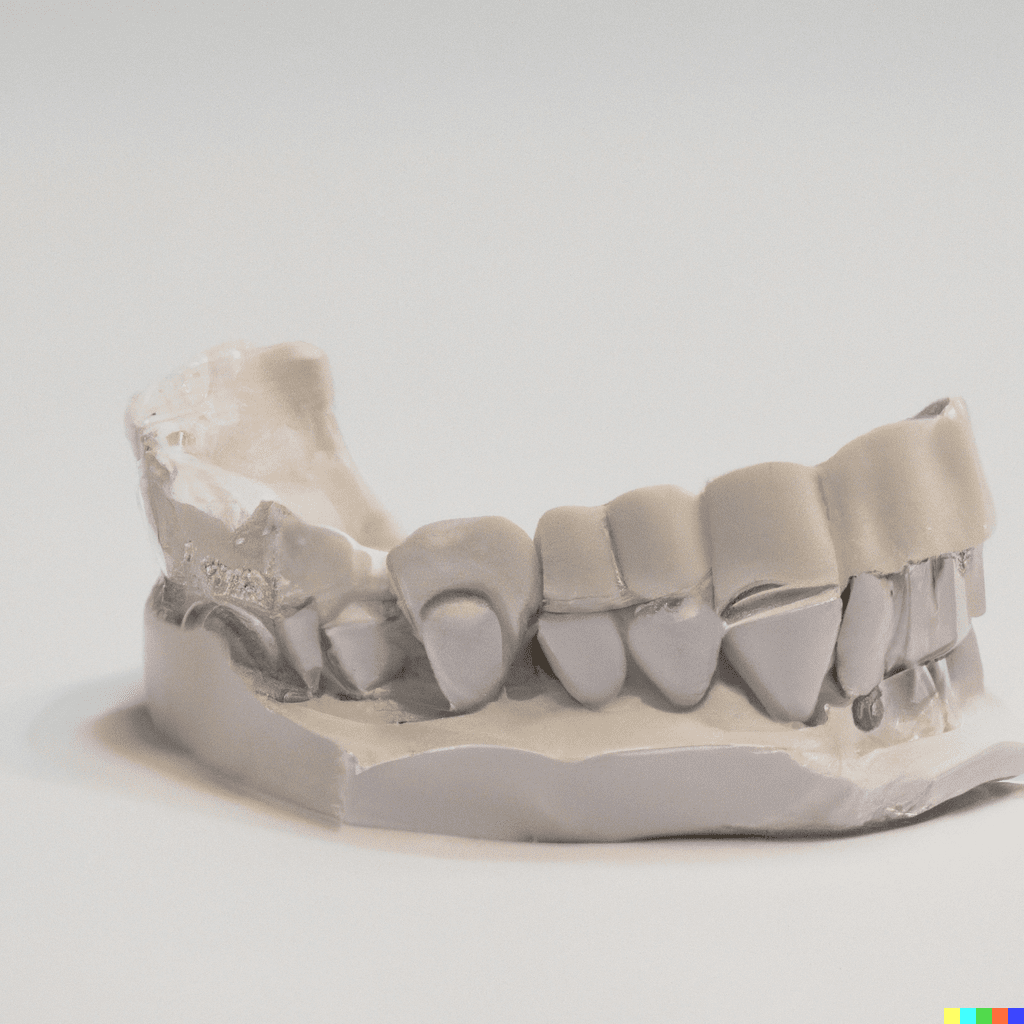

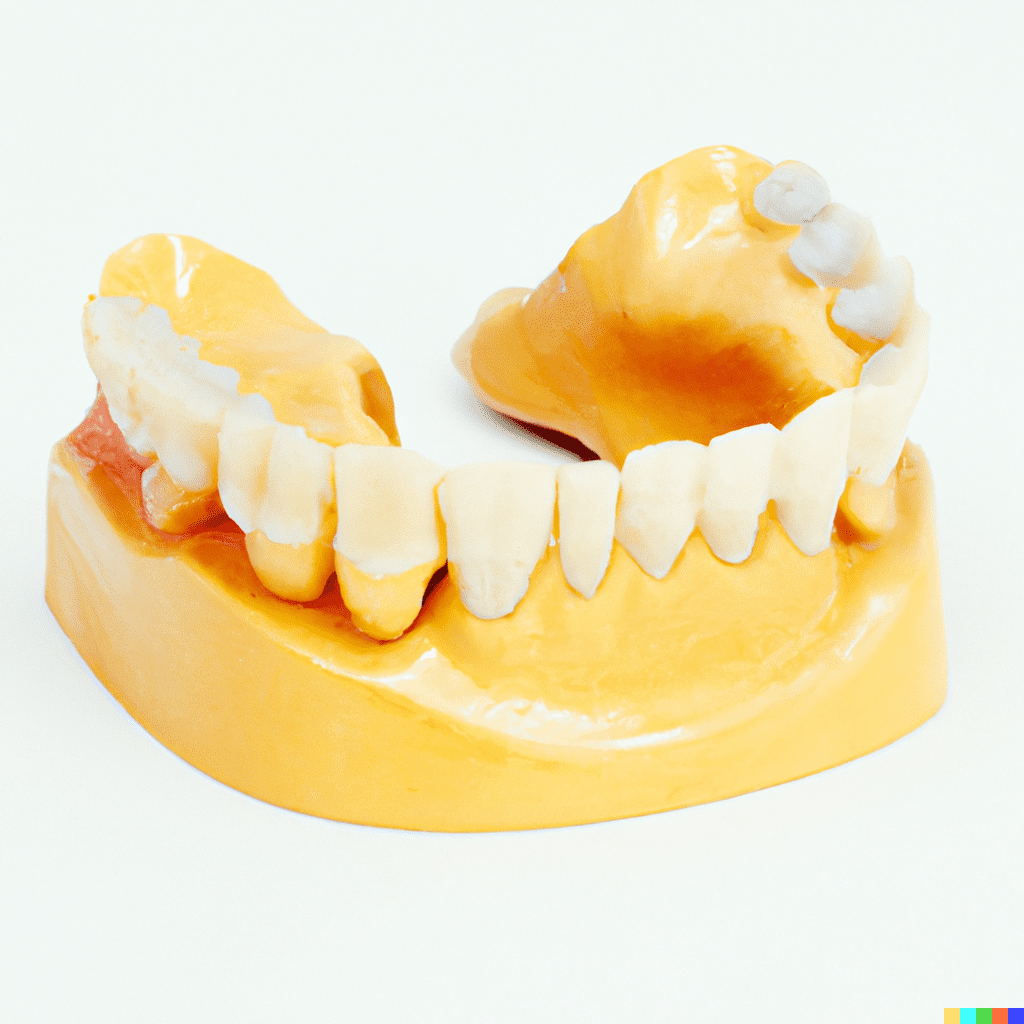

- Biocompatible, sterilizable, suitable for medical devices |

|

|

|

- Static-dissipative properties |

|

|

- Prevents electrostatic discharge, suitable for electronics |

Aerospace and Defense, Consumer Products |

|

|

- High toughness and durability |

- Density: Varies by formulation |

- Resistant to various chemicals |

- Resembles ABS but may offer specific improvements |

|

|

|

- High accuracy and resolution |

- Density: Varies by formulation |

|

- Used in stereolithography 3D printing, fine details |

Consumer Products, Medical, Aerospace and Defense |

|

|

- High strength and durability |

- Density: Varies by formulation |

|

- Tough and durable, suitable for functional prototypes |

Consumer Products, Aerospace and Defense |

|

|

|

- Density: Varies by formulation |

|

- Rigid and durable, good for functional prototypes |

Consumer Products, Aerospace and Defense |

|

|

- High transparency and clarity |

- Density: Varies by formulation |

|

- Crystal clear appearance, ideal for clear parts |

Consumer Products, Medical |

|

|

- High toughness and durability |

- Density: Varies by formulation |

|

- Resistant to high temperatures, strong and rigid |

Consumer Products, Aerospace and Defense |

|

|

- Excellent UV resistance |

|

|

- Outdoor durability, retains color and strength in sunlight |

Automotive, Consumer Products |

|

|

|

|

- Resistant to moisture, chemicals |

- Tough and durable, suitable for functional parts |

Aerospace and Defense, Automotive, Consumer Products |

|

|

- Flame retardant properties |

- Density: Varies by formulation |

|

- Fire safety, suitable for applications requiring flame resistance |

Aerospace and Defense, Automotive |

|

|

- Good chemical resistance |

|

- Resistant to oils, greases |

- Versatile, suitable for various industrial applications |

Aerospace and Defense, Automotive, Consumer Products, Oil and Gas |

|

|

|

|

- Resistant to moisture, abrasion |

- Durable, excellent for applications requiring impact resistance |

Automotive, Consumer Products |

|

|

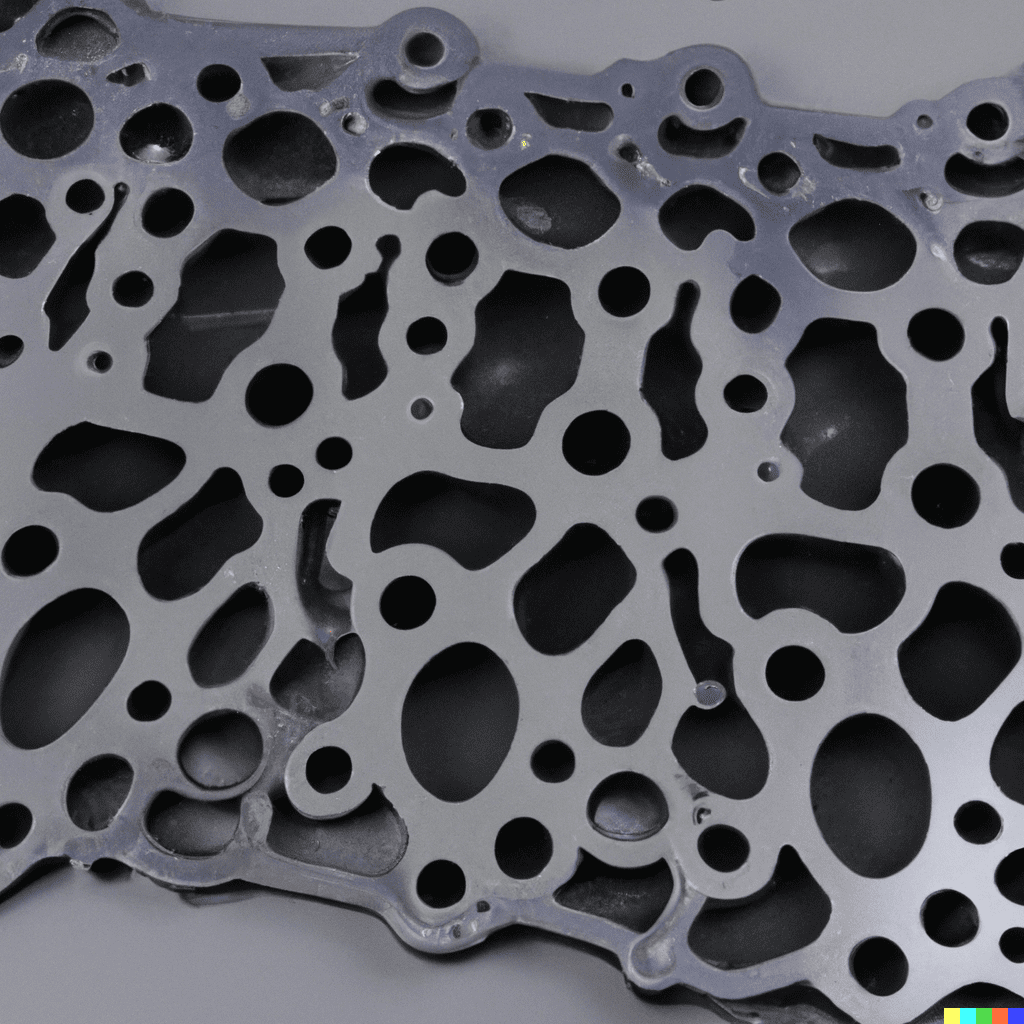

- Improved stiffness and dimensional stability |

- Density: Varies by formulation |

- Reinforced with glass beads |

- Increased stiffness, suitable for engineering applications |

Automotive, Aerospace and Defense |

|

|

- High strength and heat resistance |

- Density: Varies by formulation |

|

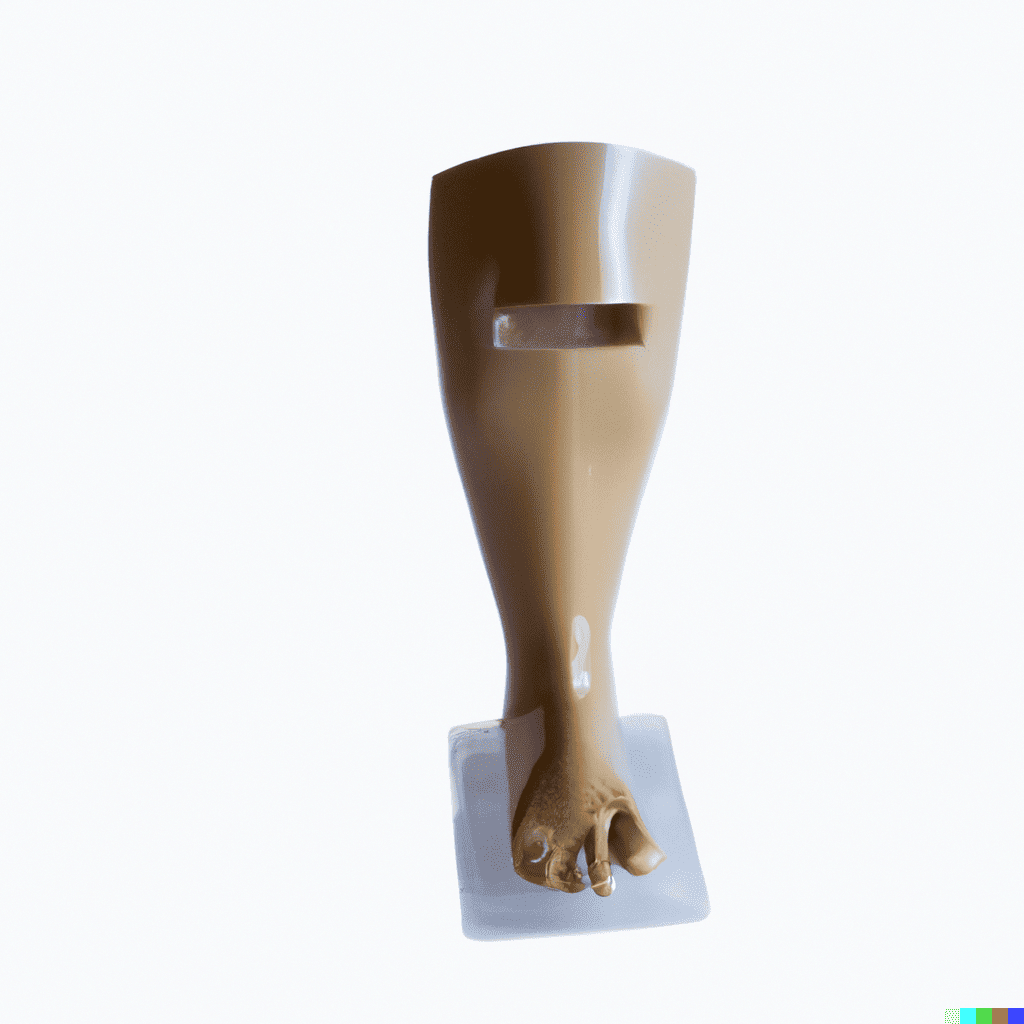

- Suitable for medical and aerospace applications |

Aerospace and Defense, Medical |

|

|

|

- Density: Varies by formulation |

|

- Blends properties of PC and ABS, versatile material |

Automotive, Consumer Products |

|

|

- Excellent transparency and impact resistance |

|

|

- Clarity and toughness, ideal for packaging and displays |

Consumer Products, Medical |

|

|

- Biodegradable and easy to print |

|

|

- Eco-friendly, easy to 3D print |

Consumer Products, Medical |

|

|

- High impact resistance, optical clarity |

|

- Excellent optical properties |

- Exceptional clarity and strength, suitable for transparent parts |

Aerospace and Defense, Consumer Products, Medical |

|

|

- Low density and good chemical resistance |

|

- Resistant to moisture, chemicals |

- Lightweight, suitable for low-stress applications |

Consumer Products, Automotive |

|

|

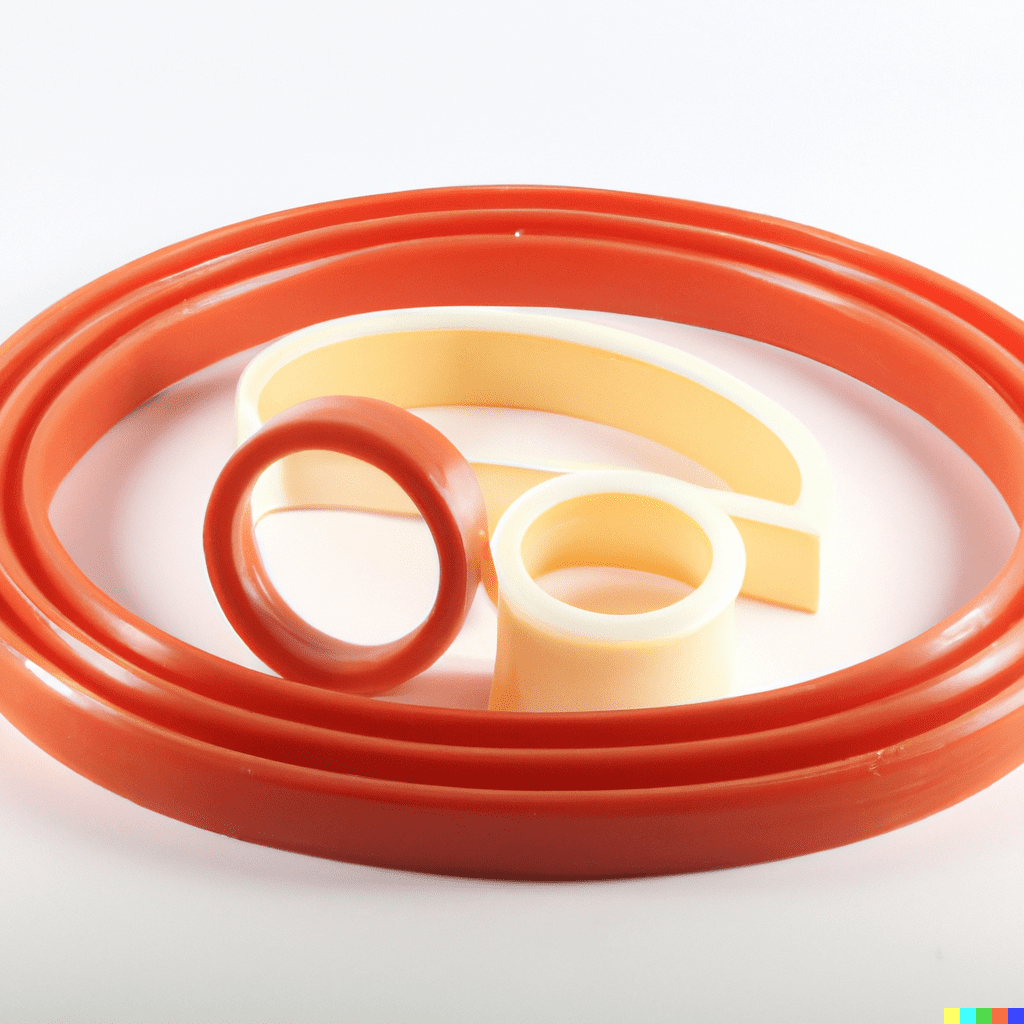

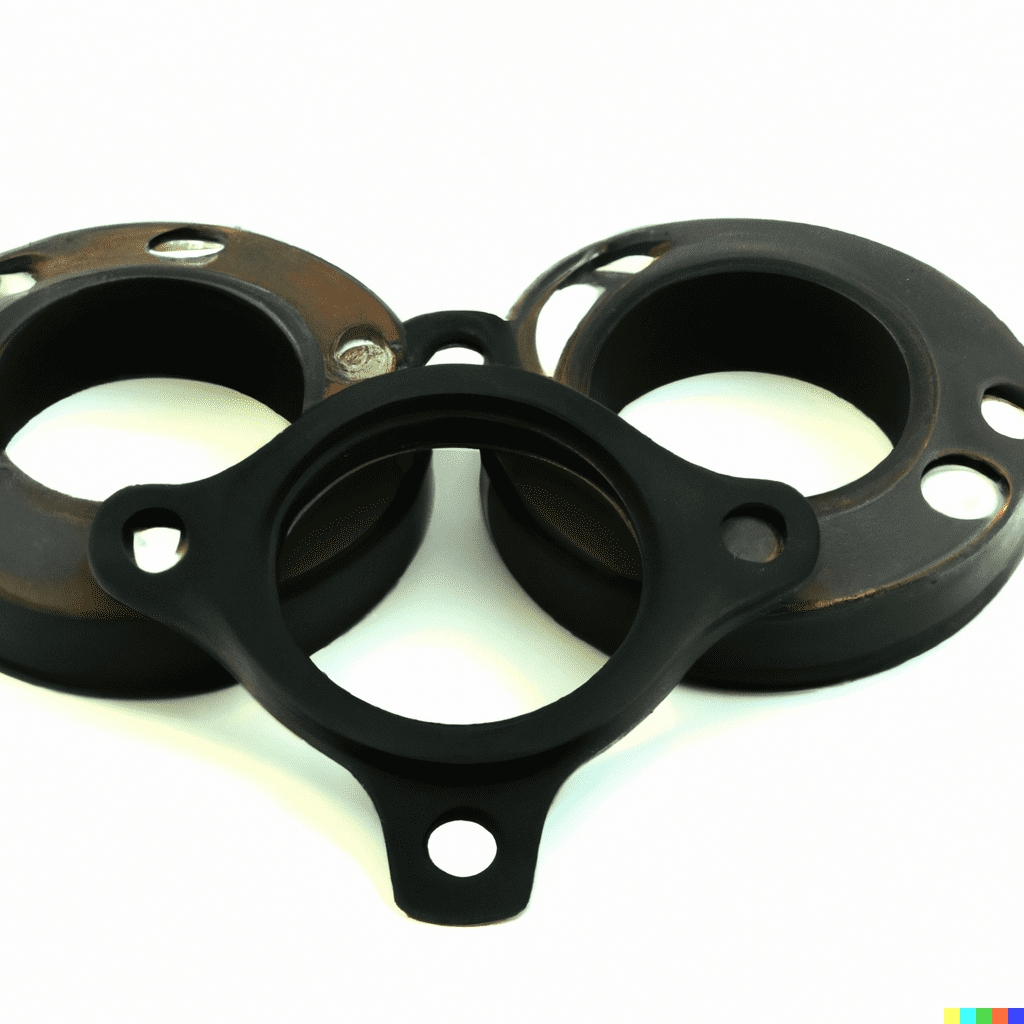

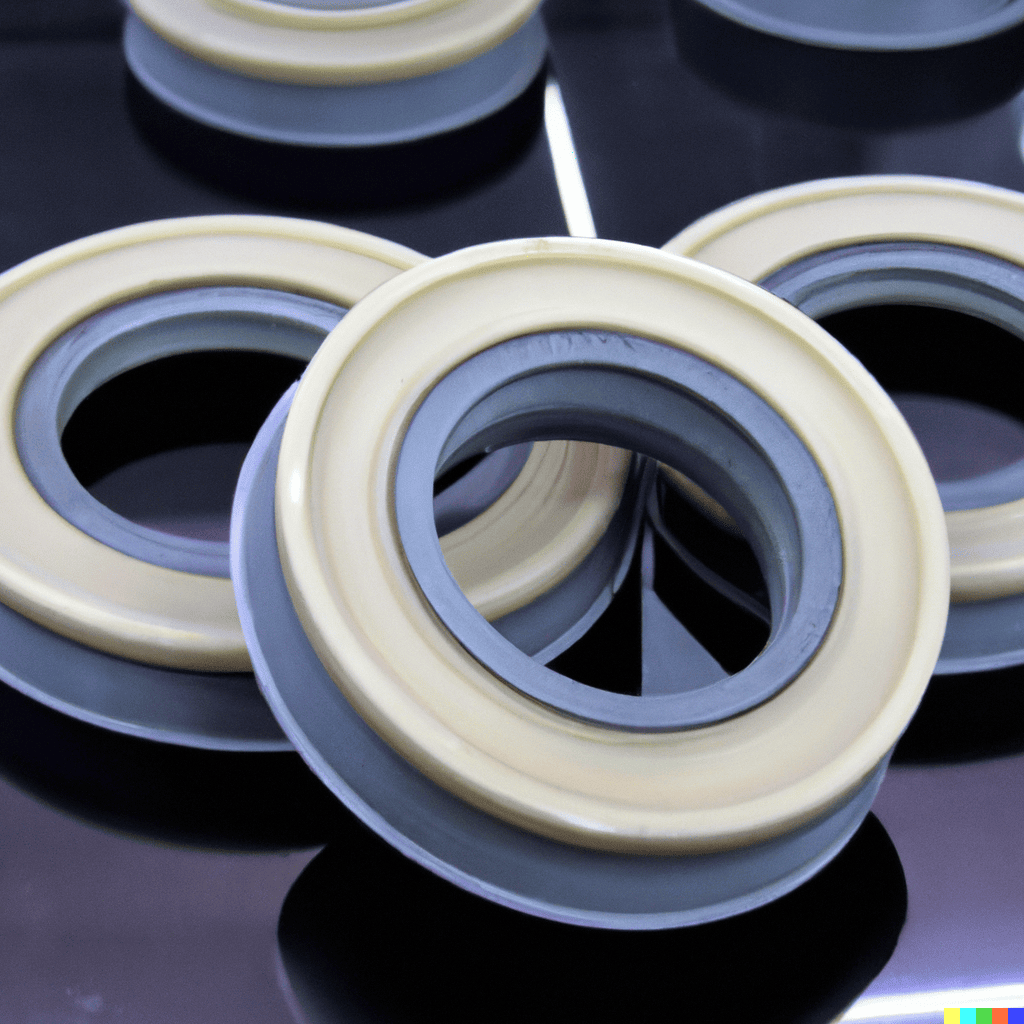

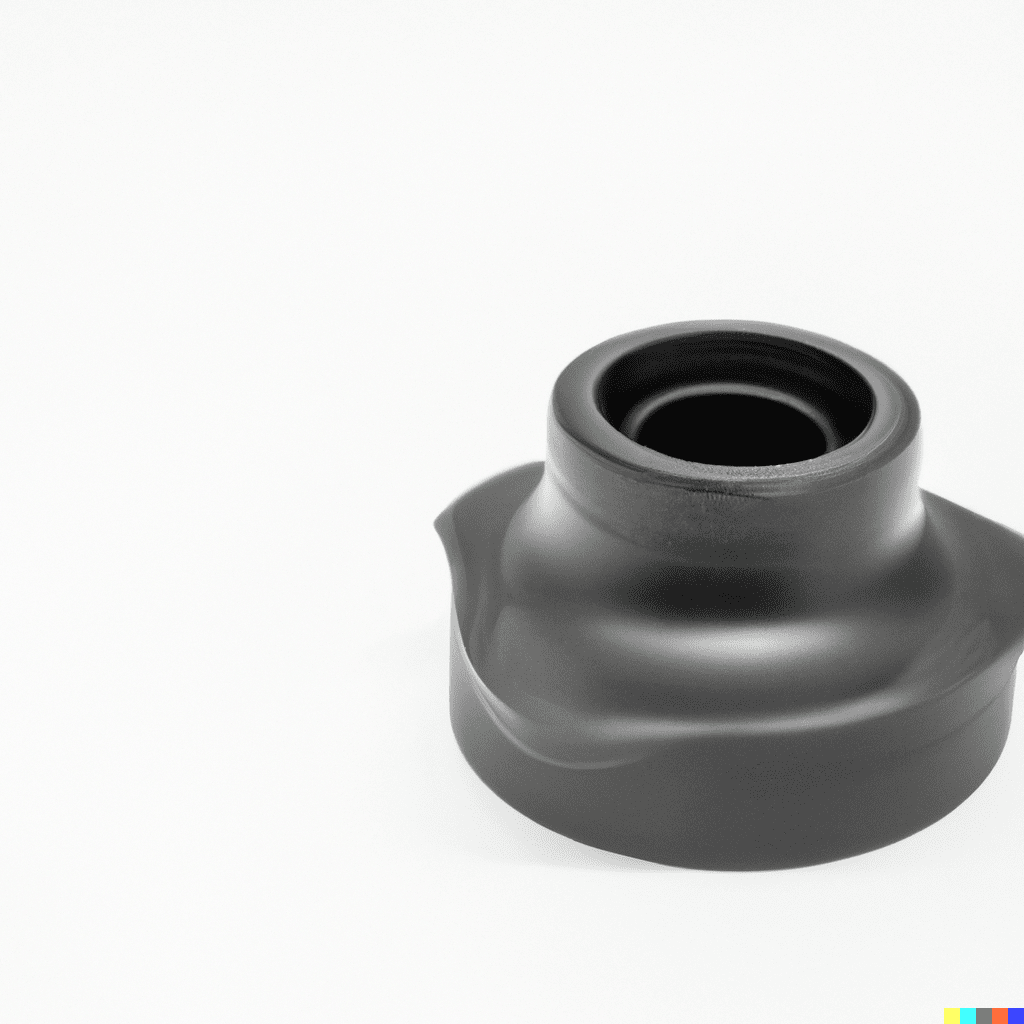

- Flexible and rubber-like properties |

- Density: Varies by formulation |

|

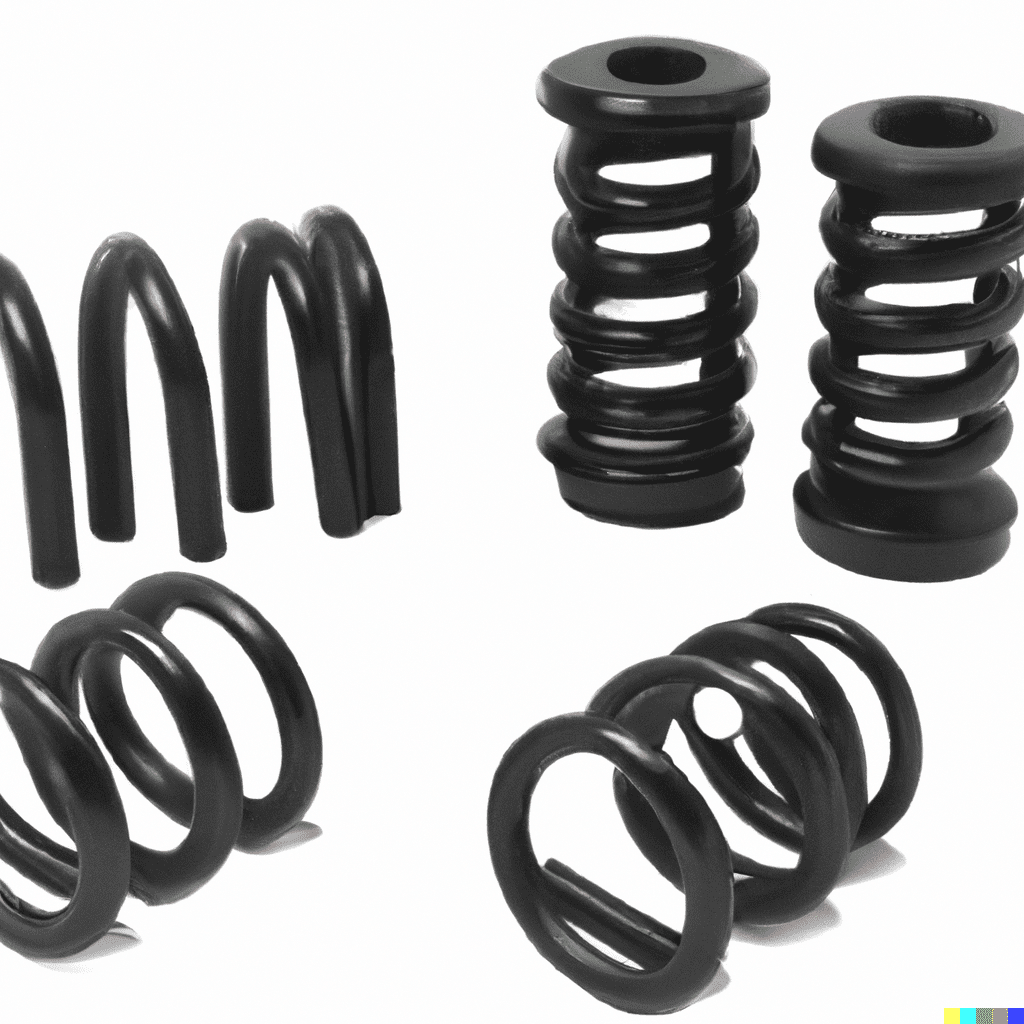

- Mimics rubber, suitable for gaskets and seals |

Automotive, Consumer Products |

|

|

- High strength and heat resistance |

- Density: Varies by formulation |

|

- Engineering-grade material, suitable for functional prototypes |

Aerospace and Defense, Automotive |

|

|

- High stiffness and heat resistance |

- Density: Varies by formulation |

|

- Strong and stiff, ideal for high-temperature applications |

|

|

|

- High transparency and clarity |

- Density: Varies by formulation |

|

- Transparent, suitable for clear prototypes and parts |

Consumer Products, Medical |

|

|

- Excellent clarity and water resistance |

- Density: Varies by formulation |

|

- Waterproof, suitable for water-resistant parts |

Consumer Products, Medical |

|

|

- High toughness and durability |

- Density: Varies by formulation |

|

- Rigid, tough, and durable, good for functional prototypes |

Consumer Products, Aerospace and Defense |

|

|

- Flexible and elastomeric properties |

- Density: Varies by formulation |

- Thermoplastic polyurethane |

- Flexibility and resilience, suitable for elastomeric parts |

Automotive, Consumer Products, Medical |

|

|

- High strength, heat, and chemical resistance |

|

- Flame-resistant, UL 94 V0 |

- Engineering-grade thermoplastic with excellent properties |

Aerospace and Defense, Automotive, Oil and Gas |

|

|

- High strength, heat, and chemical resistance |

|

- Flame-resistant, UL 94 V0 |

- Suitable for aerospace and transportation applications |

Aerospace and Defense, Automotive |

|

|

|

- Density: Varies by formulation |

|

- Versatile material, good for prototypes and models |

Consumer Products, Aerospace and Defense |

|

|

- High transparency and clarity |

- Density: Varies by formulation |

|

- Transparent appearance, ideal for clear parts |

Consumer Products, Medical |